Porous carbon material capable of selectively absorbing gold ions, preparation method and application of porous carbon material

A porous carbon material and gold ion technology, applied in the field of porous carbon, can solve the problems of poor selectivity and small adsorption capacity, and achieve the effects of low cost, simple preparation process and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

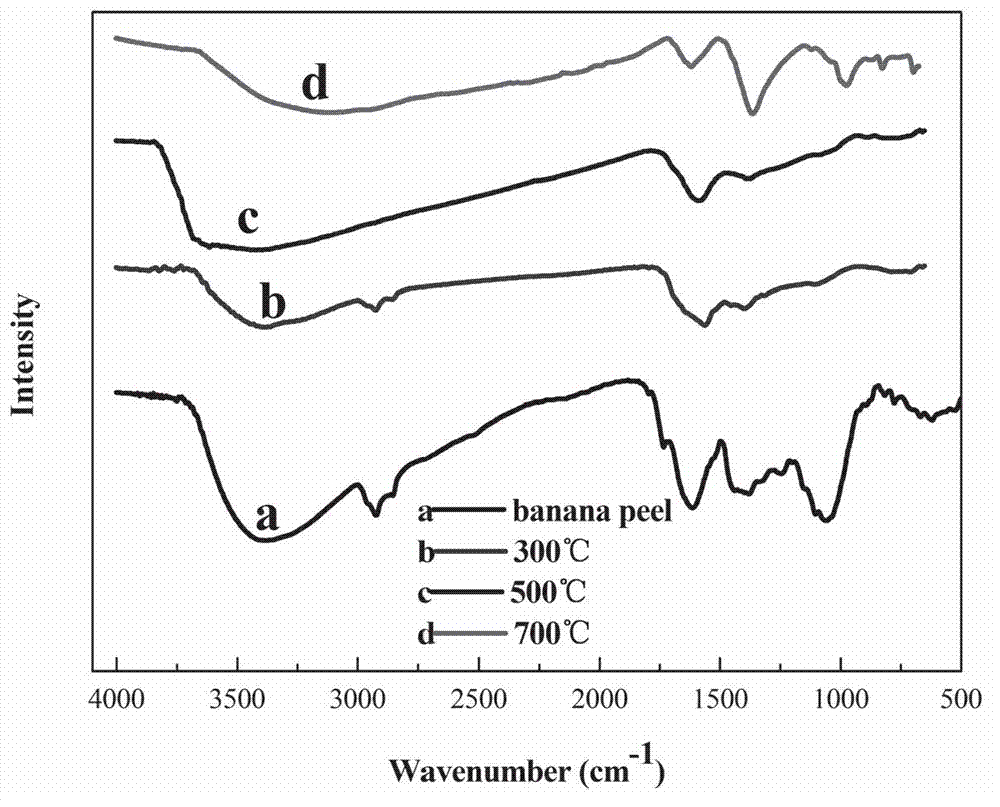

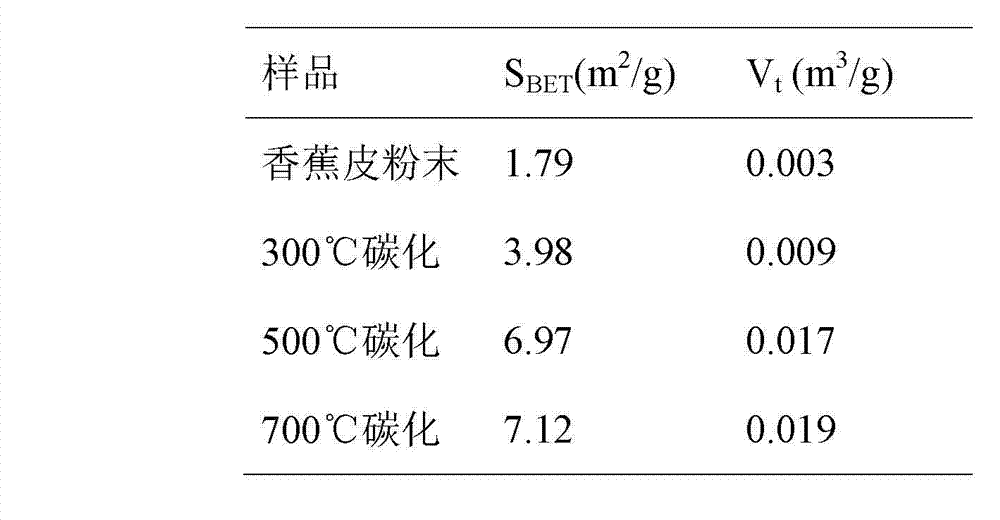

[0031] Example 1: Preparation and characterization of porous carbon materials at different carbonization temperatures

[0032] 1. Soak the banana peel of the domestic sesame banana in the pool and rinse it with running water. After rinsing the surface dirt, rinse it twice with distilled water. Then put it in a blast drying oven, bake at 80°C for 48 h, crush it with an electric grinder, and sieve it with a 100-mesh sieve to obtain banana peel powder.

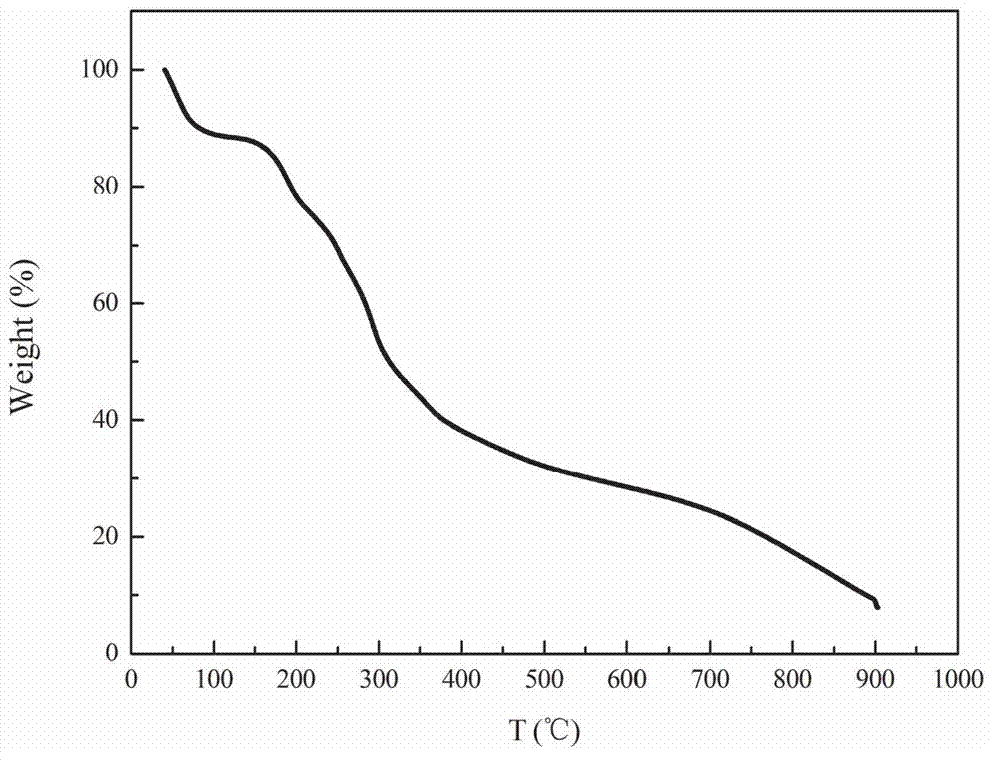

[0033] 2. Carry out thermogravimetric performance analysis to the obtained banana peel powder, the thermogravimetric analysis of banana peel powder is as follows: figure 1 shown. from figure 1 It can be seen from the figure that 50-200°C is the water evaporation stage remaining in the banana peel; while in the temperature range of 200-700°C, it is the hemicellulose, cellulose, lignin and other polysaccharides and proteins in the banana peel. Wait for the splitting and decomposition stage of biomass; after 700°C, the biomass of...

Embodiment 2

[0042] Example 2: Testing of the adsorption performance of porous carbon materials prepared at 500°C on gold ions

[0043] 1. Prepare AuCl with a concentration of about 2, 3, 4, and 5mmol / L respectively 3 Solution, its accurate concentration is determined by atomic absorption spectrometry, and its test accuracy reaches 0.0001g.

[0044] 2. An analytical balance accurately weighed 0.0180 g of the porous carbon material prepared by carbonization at 500°C in Example 1, and put into 10 ml of the above-mentioned four kinds of AuCl with a pH value of 2.50 3 After stirring for 2 h at room temperature, the porous carbon material adsorbed with gold was filtered out and the gold content in the filtrate was measured, and the adsorption capacity and adsorption efficiency were calculated. The specific results are shown in Table 3. As can be seen from Table 3, with the AuCl in the solution 3 As the concentration increases, the adsorption capacity of porous carbon materials increases, when...

Embodiment 3

[0047] Example 3: Testing of adsorption properties of banana peel powder and porous carbon materials prepared by carbonization at 300°C and 700°C

[0048] An analytical balance accurately weighed 0.0180 g of banana peel powder and the porous carbon material prepared by carbonization at 300°C and 700°C in Example 1, and put in 10 ml of AuCl with a pH value of 2.50 and a concentration of 1354mg / L 3 solution, stirred at room temperature for 2 h, and then filtered out the porous carbon material adsorbed with gold. The gold content in the filtrate was determined by atomic absorption spectrometry to be 1120, 537, and 1270 mg / L, and the calculated adsorption capacity was 198.31 mg / L. , 692.37, 71.19 mg / g, and the adsorption efficiencies were 17.28%, 60.34%, and 6.20%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com