Method for preparing through-type composite strip embedded with silver copper

A composite strip, silver-clad copper technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of not being suitable for mass production, limited service life of mold hot-pressing devices, and high requirements for manufacturing equipment capabilities. Achieve the effect of facilitating automatic processing, enhancing the bonding firmness, and requiring less manufacturing equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

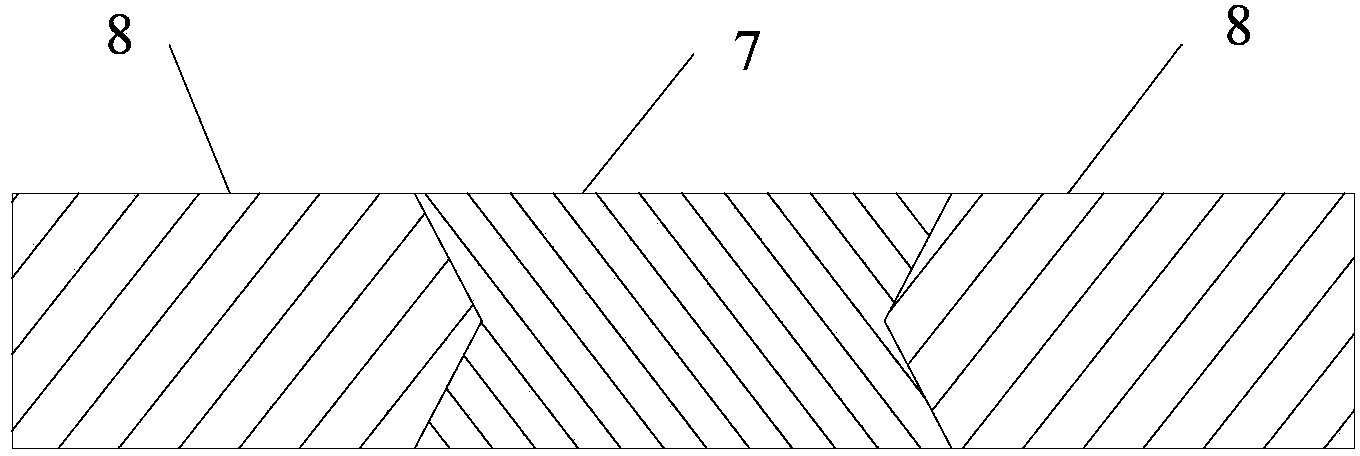

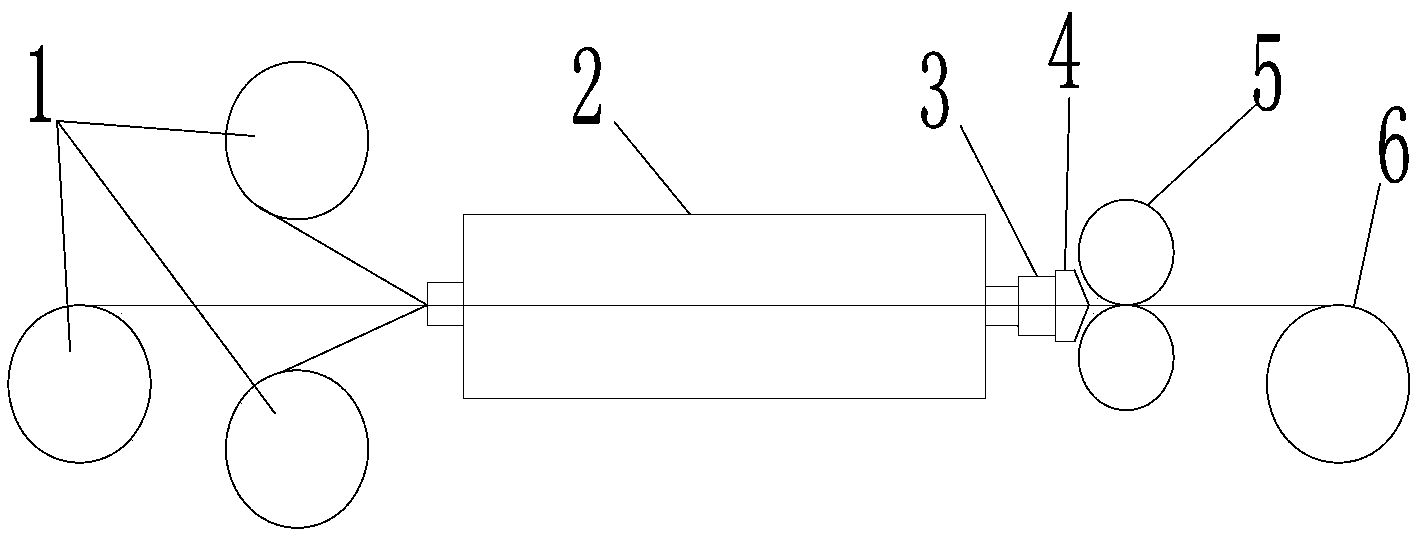

[0035] Example 1 A preparation method of a silver-coated copper composite strip alternately. The prepared silver ingot is extruded into a special-shaped silver strip and the surface of the purchased special-shaped copper strip is cleaned. The two sides of a silver strip are centered and recessed inward with a depth of 3mm, and the angle It has a concave angle of 118°, a total width of 30mm and a thickness of 10mm. The two copper strips have a convex angle of 3mm centered on one side and an angle of 118°, with a total width of 25mm and a thickness of 10mm. One silver strip and two copper strips form a composite blank. Remove the oil and impurities from the surface of the silver and copper belts. The material is acidified, polished and dried to obtain a clean composite blank. The sulfuric acid concentration is 15%. The polishing material is a steel wire wheel. The diameter of the steel wire is ¢0.1mm, and the cleaning speed is 2.5m / min. Place the cleaned material on the discha...

Embodiment 2

[0036] Example 2 A method for preparing two silver-coated copper composite strips alternately. The prepared silver ingots are extruded into special-shaped silver strips and the surface of the purchased special-shaped copper strips is cleaned. Both sides of the two silver strips are centered and inwardly recessed to a depth of 3.5 mm, concave angle of 104°, total width 15mm, thickness 9mm. Two copper strips have a convex angle of 3.5mm centered on one side and an angle of 104°, with a total width of 20mm and a thickness of 9mm. One copper tape has a centered convex angle of 3.5mm on both sides and an angle of 104°, with a total width of 15mm. The thickness is 9mm. Two silver strips and three copper strips form a composite blank. Remove the oil and impurities from the surface of the silver and copper belts. The materials are acidified, polished and dried to obtain a clean composite blank. The sulfuric acid concentration is 13%. The polishing material is a steel wire wheel. The d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com