Preparation method for Mitiglinide calcium

A mitiglinide calcium and action technology, which is applied in the preparation field of mitiglinide calcium to achieve the effects of reducing environmental pollution, friendly reaction conditions and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

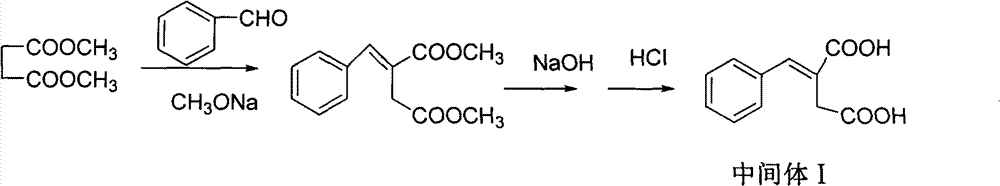

[0025] Step 1: Preparation of 2-benzylidene succinic acid.

[0026] Feeding amount

[0027] raw material

molecular weight

Feeding amount

moles

The molar ratio of

146

5.85kg

40.1

1

106

2.12kg

20

0.5

54

1.52kg

28.1

0.7

-

5.7L

--

--

caustic soda

40

2.3kg

57.5

1.4

36.5

8.7L

88.7

2.2

[0028] Put dimethyl succinate, methanol, and sodium methoxide into the reaction kettle in turn, start stirring, turn on the heating system of the reaction kettle, and after reflux, add benzaldehyde dropwise. Continue to stir and reflux for a period of time, then heat to evaporate methanol, cool to room temperature, add about 23L caustic soda solution, heat to reflux for 1 hour, cool to room temperature, add ethyl acet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com