Ink-jet printing preparation method of organic solar battery optical active layer film

A solar cell and photoactive layer technology, which is applied in the field of solar cells, can solve the problems of excessive fluctuations in the surface height of the photoactive layer film of organic solar cells, and the slow drying rate of the solution, so as to achieve good leveling, good solubility, Guaranteed solubility and stability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The invention provides an inkjet printing preparation method of a photoactive layer film of an organic solar cell, comprising the following steps:

[0025] Step 1: Mix the base solvent and the added solvent to form a mixed solvent, weigh the electron donor material P3HT (poly-3-hexylthiophene) and the electron acceptor material PC61BM (2ALPHA-phenyl-1,2(2ALPHA)-high[ 5,6] fullerene-C60-LH-2ALPHA-butyric acid methyl ester), added to the mixed solvent to dissolve to form a mixed solution; the base solvent is chlorobenzene, and the added solvent is o-dichlorobenzene, tetrahydronaphthalene , trimethylbenzene or chloronaphthalene, the volume percentage of the base solvent and the added solvent in the mixed solvent is (80%~98%): (2%~20%);

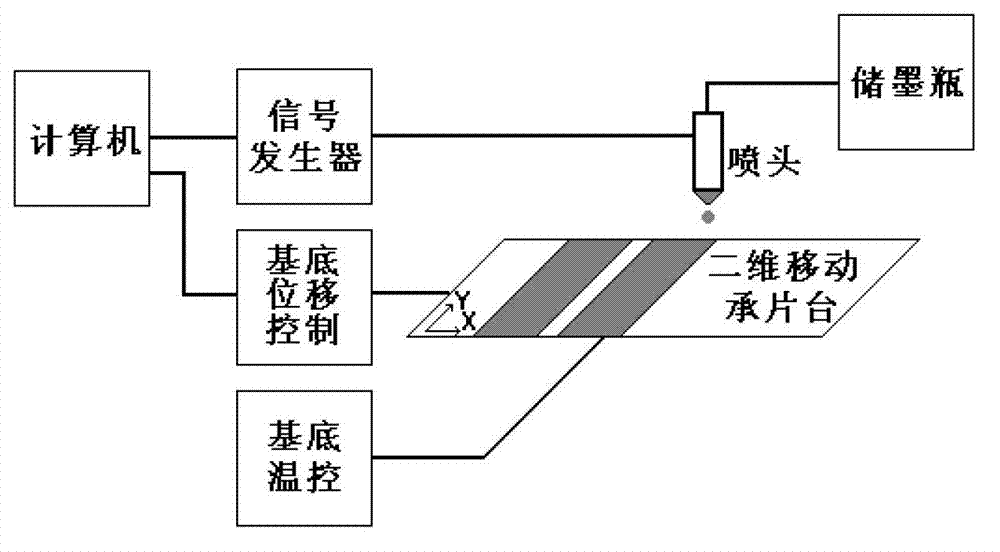

[0026] Step 2: Deposit the mixed solution obtained in Step 1 on the surface of the substrate provided with a hole injection layer and a transparent conductive layer through an inkjet printing device. The thickness of the printing liquid la...

Embodiment 1

[0033] (1) Solution configuration

[0034] Measure 9.0 ml of base solvent chlorobenzene and 1.0 ml of added solvent chloronaphthalene, mix them to form a mixed solvent, then weigh 50 mg of electron donor material P3HT and 50 mg of electron acceptor material PC61BM, add them to the mixed solvent at 40 °C dissolved to form a mixed solution;

[0035] (2) Preparation of photoactive layer by inkjet printing

[0036] Deposit the mixed solution obtained in step (1) on the surface of the substrate provided with the PEDOT hole injection layer and the ITO transparent conductive layer through an inkjet printing device. The thickness of the printing solution layer is 20 microns, and the substrate temperature is 20°C. After the solution is dried The photoactive layer thin film of the organic solar cell is obtained.

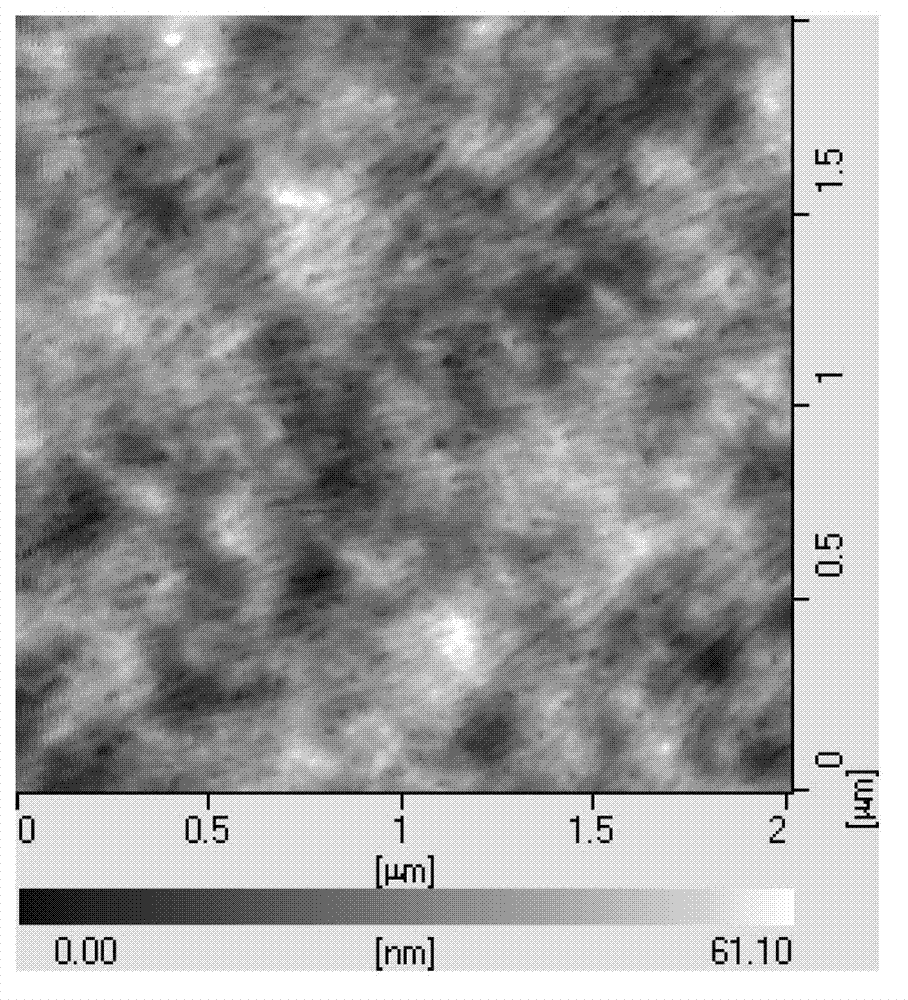

[0037] figure 2 It is an atomic force microscope surface topography picture of the organic solar cell photoactive layer film obtained in Example 1. The experimental result...

Embodiment 2

[0039] (1) Solution configuration

[0040] Measure 9.0 ml of base solvent chlorobenzene and 1.0 ml of added solvent trimethylbenzene, mix them to form a mixed solvent, then weigh 50 mg of electron-donor material P3HT and 50 mg of electron-acceptor material PC61BM, add them to the mixed solvent at 70°C dissolved to form a mixed solution;

[0041] (2) Preparation of photoactive layer by inkjet printing

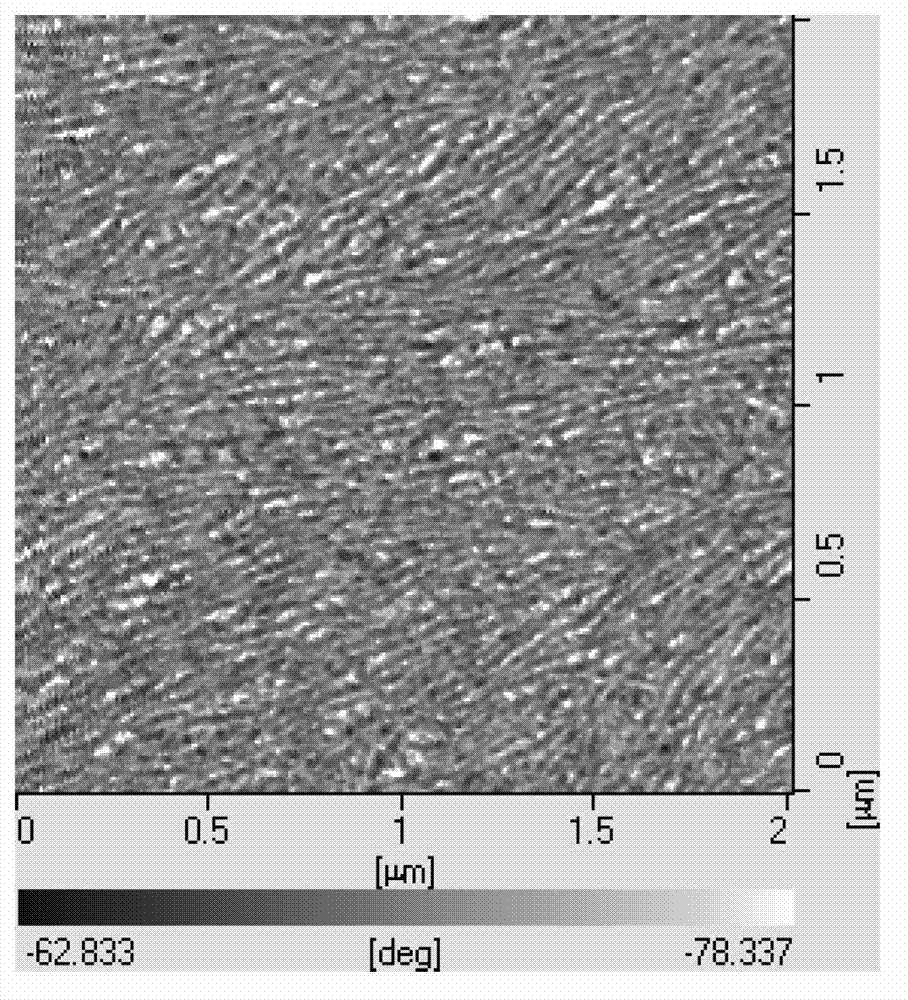

[0042] The mixed solution obtained in step (1) is deposited on the surface of the substrate provided with the PEDOT hole injection layer and the ITO transparent conductive layer through an inkjet printing device. The thickness of the printing solution layer is 40 microns, and the substrate temperature is 20 ° C. After the solution is dried The photoactive layer thin film of the organic solar cell is obtained. Figure 4 It is an atomic force microscope surface topography picture of the organic solar cell photoactive layer film obtained in Example 2. The experimental results sho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com