Stable preparation of phosphatidylserine and preparation method, application as well as application product of stable preparation

A technology for phosphatidylserine and stable preparations, which is applied in the fields of biomedicine and food processing, and can solve problems such as difficult production and preparation, easy oxidation and discoloration, and unstable physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

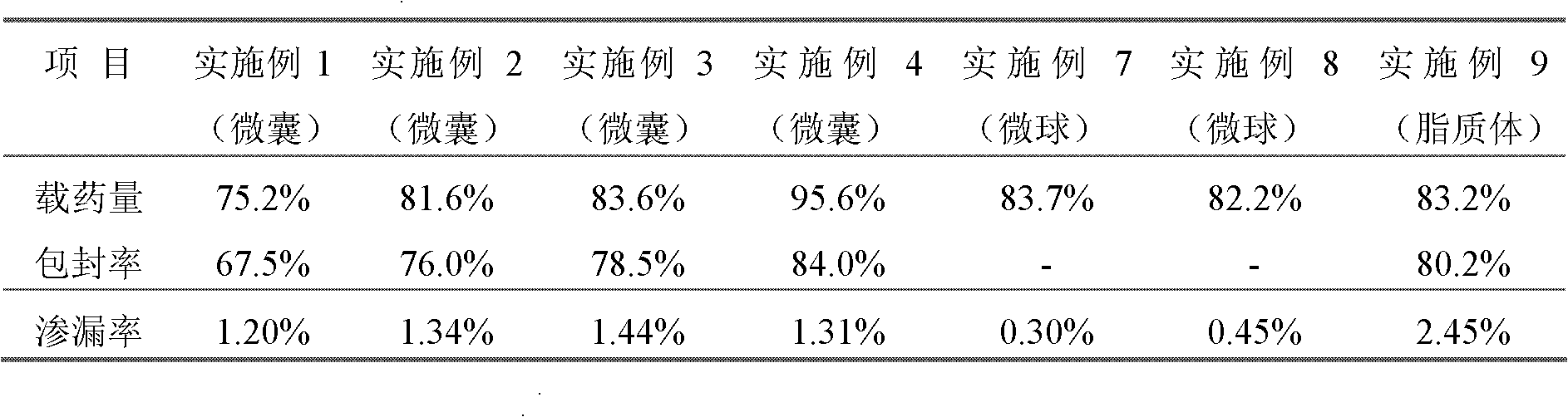

Examples

Embodiment 1

[0067] Add 100 grams of sodium alginate to 1 liter of purified water at 50-60°C and stir to form a uniform aqueous solution. Gradually add 200 grams of ground phosphatidylserine roughened product (containing 50 parts of phosphatidylserine), fully stir and homogenize. Another 1 liter of 50-60° C. purified gelatin aqueous solution was prepared, with a concentration of 5%. Stir constantly in a constant temperature water bath to swell completely. The above-mentioned sodium alginate solution and gelatin solution are combined and fully stirred to form a cystic solution. Add purified water (V / V, 1:1) to the cyst-forming solution, adjust the pH range to 3.9-4.2 with an appropriate amount of 5% dilute acetic acid; 2 As a curing agent, lower the temperature and control the temperature at 10°C to 15°C to form microcapsules of phosphatidylserine. The microcapsules were collected by filtration, washed with water, dried, and set aside.

[0068] In other embodiments of the present invent...

Embodiment 2

[0070] Add 100 grams of sodium alginate to 1 liter of purified water at 50-60° C. and stir to form a uniform aqueous solution, and stir until dispersed. Gradually add 200 grams of ground phosphatidylserine roughened product (containing 50 parts of phosphatidylserine), fully stir and homogenize. Another 1 liter of purified water at a temperature of 50-60° C. is used to fully soak and swell the chitosan at a concentration of 0.5%. The above-mentioned sodium alginate solution and chitosan solution are combined and fully stirred to form a cystic solution. Purified water (V / V, 1:2) was added to the cyst-forming solution, and about 100ml of 0.25M CaCl 2 As a curing agent, lower the temperature and control the temperature at 10°C to 15°C. Forms microcapsules of phosphatidylserine. The microcapsules were collected by filtration, washed with water, dehydrated with absolute ethanol, dried, and set aside.

Embodiment 3

[0072] Mix and grind 50 grams of gum arabic and 200 grams of phosphatidylserine roughened product (containing 40 parts of phosphatidylserine). Add to 1 liter of purified water at 50-60°C and stir to form a homogeneous aqueous solution. Another 1 liter of purified aqueous solution of 5% gelatin at a temperature of 50-60° C. was prepared. Stir constantly in a constant temperature water bath to swell completely. The above-mentioned gum arabic solution and gelatin solution are combined and stirred thoroughly to form a cystic solution. Purified water (V / V, 1:3) was added to the cyst-forming solution, and an appropriate amount of 5% dilute acetic acid was used to adjust the pH range to 4.1-4.5; the stirring was continued for 1 hour. The solution was adjusted to pH 8-9 with 20% sodium hydroxide. About 50ml of 30% formaldehyde solution is used as a curing agent, the temperature is lowered and cured, and the temperature is controlled at 10°C to 15°C to form microcapsules of phosphat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com