Method for preparing fish oil ethyl ester by microwave esterification and purifying ethyl eicosapentaenoate

A technology of fatty acid ethyl ester and fish oil, which is applied in the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds. It can solve the problems of small processing capacity, achieve large processing capacity, fast speed, and avoid heavy metal ions or toxic The effect of the use of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The raw material used in this example is a certain crude fish oil glyceride, and the acid value measured by the national standard GB-T5530-2005 method is 12.38mgKOH / g.

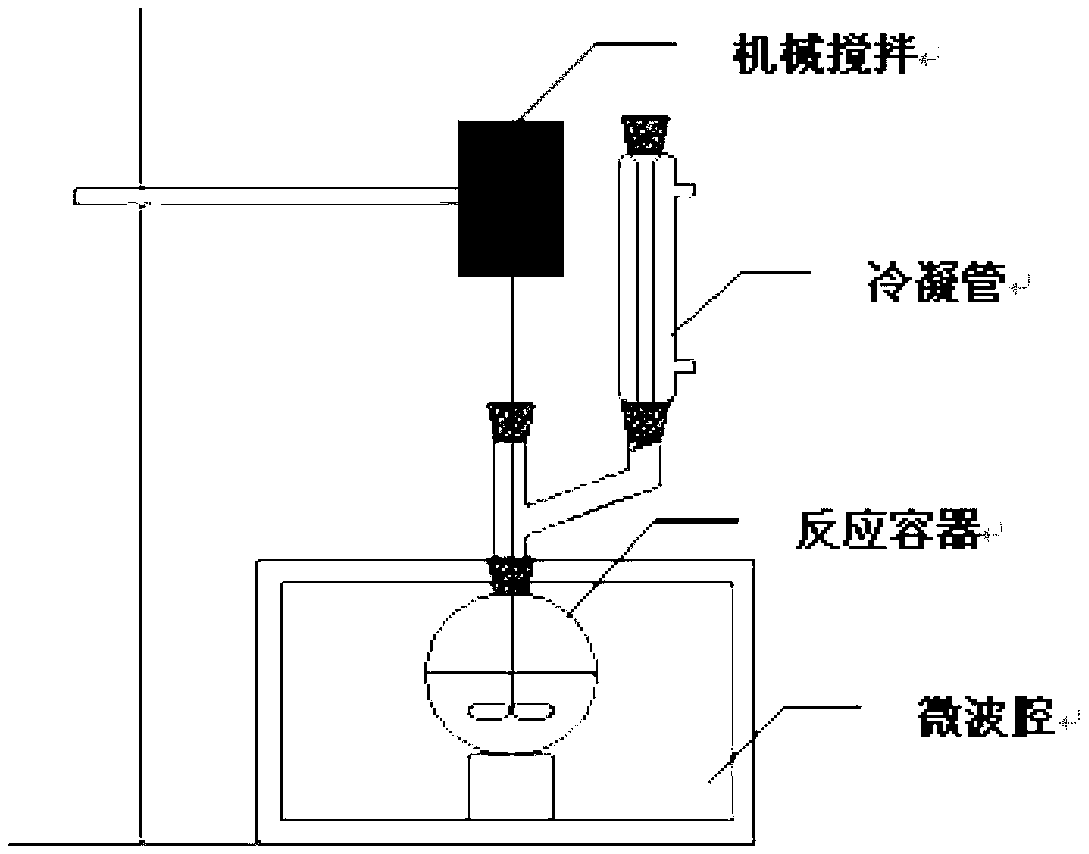

[0028] 1) Pre-esterification of fish oil: figure 1 500g of fish oil, 10g of concentrated sulfuric acid, and 500g of absolute ethanol were added to a round-bottomed flask, the round-bottomed flask was placed in a microwave reaction chamber, the microwave power was set to 300W, and the mechanical stirring was refluxed for 20 minutes; The pre-esterified product was washed with water until neutral, and excess ethanol and water were distilled under reduced pressure.

[0029] About 510 g of the pre-esterification product was obtained, and the acid value of the above-mentioned pre-esterification product was measured by the national standard GB-T5530-2005 method: S=1.38mgKOH / g.

[0030] 2) transesterification of fish oil: figure 1 , take 10g KOH and 500g absolute ethanol to make a solution, add it into a roun...

Embodiment 2

[0038] This example adopts the crude fish oil glyceride in embodiment 1 as raw material.

[0039] 1) Pre-esterification of fish oil: Take 500g of fish oil, 5g of concentrated sulfuric acid, and 200g of absolute ethanol into a round-bottomed flask, place the round-bottomed flask in a microwave reaction chamber, set the microwave power to 800W, mechanically stir and reflux for 10 minutes; the reaction is complete Finally, the pre-esterified product was washed with hot distilled water until neutral, and excess ethanol and water were distilled under reduced pressure. The acid value of the pre-esterified product was 0.96 mgKOH / g.

[0040] 2) Transesterification of fish oil: Take 2.5g KOH and 200g absolute ethanol to make a solution, add it into a round-bottomed flask containing 500g of pre-esterified fish oil, place the round-bottomed flask in a microwave reaction chamber, and set the microwave power to 500W, stir and reflux for 15 minutes. After the reaction was completed, the p...

Embodiment 3

[0044] The raw material used in this example is a certain crude fish oil glyceride, and the acid value is 9.68mgKOH / g after determination.

[0045] 1) Pre-esterification of fish oil: Take 500g of fish oil, 2.5g of concentrated sulfuric acid, and 150g of absolute ethanol into a round-bottomed flask, place the round-bottomed flask in a microwave reaction chamber, set the microwave power to 500W, and mechanically stir and reflux for 30 minutes; After completion, the pre-esterified product is washed with hot distilled water until neutral, and excess ethanol and water are distilled under reduced pressure. The acid value of the pre-esterified product was 1.06 mgKOH / g.

[0046] 2) Transesterification of fish oil: Take 5g KOH and 150g absolute ethanol to make a solution, add it into a round-bottomed flask containing 500g of pre-esterified fish oil, place the round-bottomed flask in a microwave reaction chamber, and set the microwave power to 800W , stirred and refluxed for 5 minutes....

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com