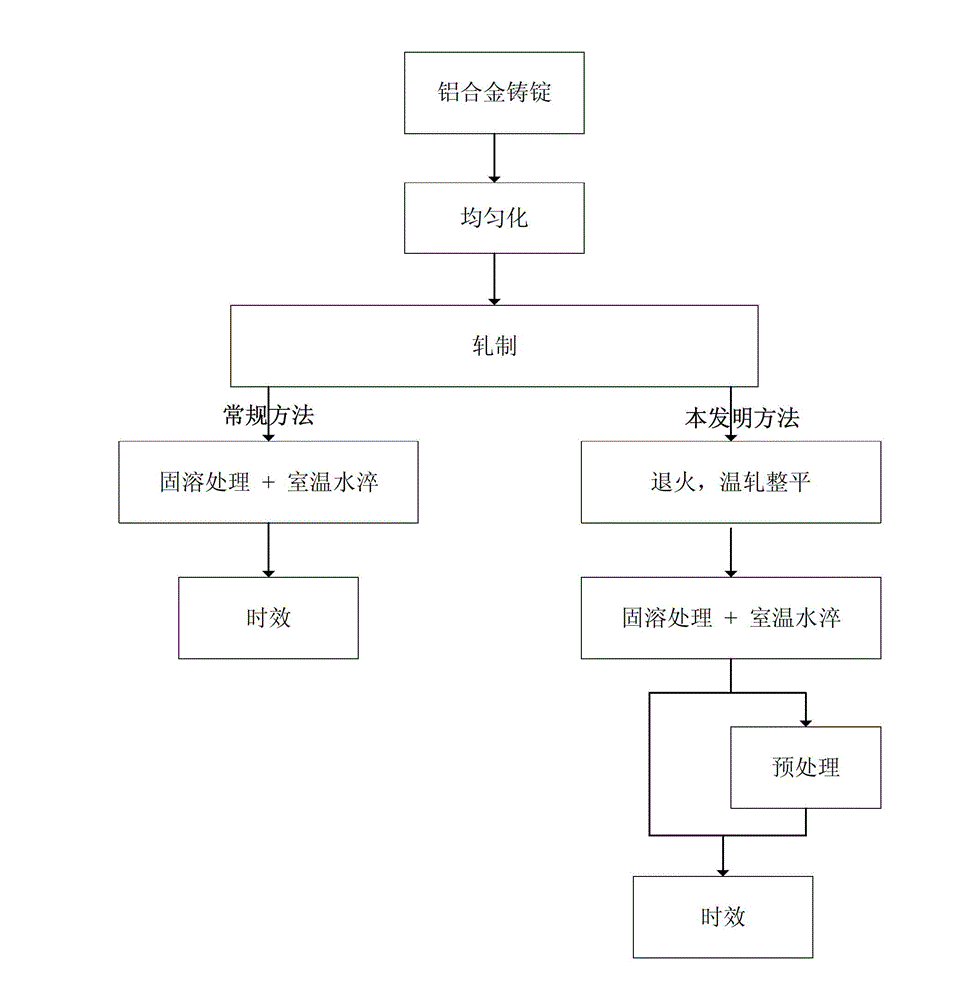

Method of reducing residual stress and quenching deformation non-uniformity of aluminum alloy after deformation

A technology of residual stress and quenching deformation, which is applied in the fields of reducing residual stress after deformation of aluminum alloys and non-uniformity of quenching deformation, can solve problems such as reducing and reducing residual stress, and achieve reduction of residual stress, increase of deformation heat treatment process, and serious warping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

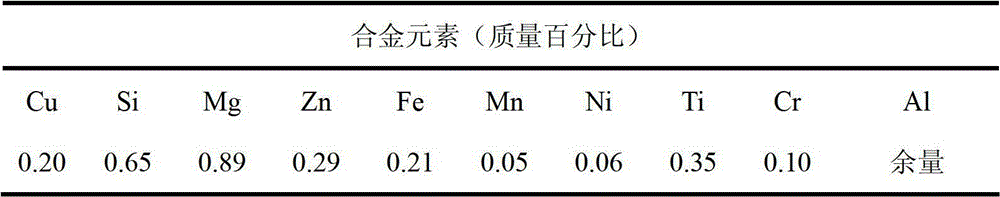

[0028] After the aluminum alloy ingot is rolled in a hot rolling mill, the plate is annealed at 350°C / 2h in a resistance heating furnace. After the annealing treatment, it is leveled with a hot rolling mill. 0.5%. The total temperature deformation is 3%, solution treatment is carried out in the air furnace, put into water for quenching within 20 seconds after the solution treatment is completed, and take it out of the water pool after the temperature of the plate drops below 50°C and dry it in the air. deal with.

Embodiment 2

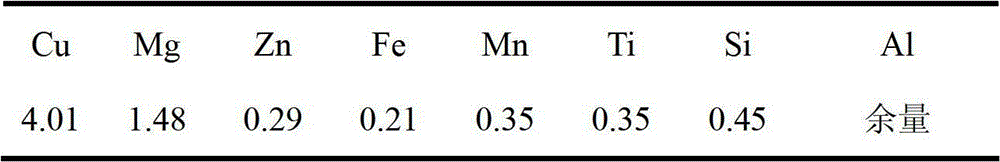

[0030] After the B aluminum alloy ingot is rolled by a hot rolling mill, the plate is annealed at 350°C / 4h in a resistance heating furnace. 0.5%. The total amount of thermal deformation and deformation is 4%. The plate is subjected to solution treatment in a salt bath furnace. After the solution treatment is completed, it is quenched in water within 20 seconds. After the temperature of the plate drops below 50°C, it is taken out of the pool and dried. , pre-stretched to 3% of the total length, and then aged.

Embodiment 3

[0032] After the C aluminum alloy ingot is rolled by a hot rolling mill, the plate is annealed at 350°C / 4h in a resistance heating furnace. 0.5%). The total temperature deformation is 5%. After the solid solution treatment, it is quenched in a roller hearth furnace. After the temperature of the plate drops below 50°C, it is taken out and dried, pre-compressed by 5% of the total thickness, and then quenched and aged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com