Solar-cell backsheet and solar-cell module

A technology for solar cells and back sheets, applied in circuits, applications, photovoltaic power generation, etc., can solve the problems of reduced adhesive adhesion, increased manufacturing costs, insufficient adhesion, etc., and achieves excellent adhesion durability, Low manufacturing cost, excellent weather resistance and water vapor barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

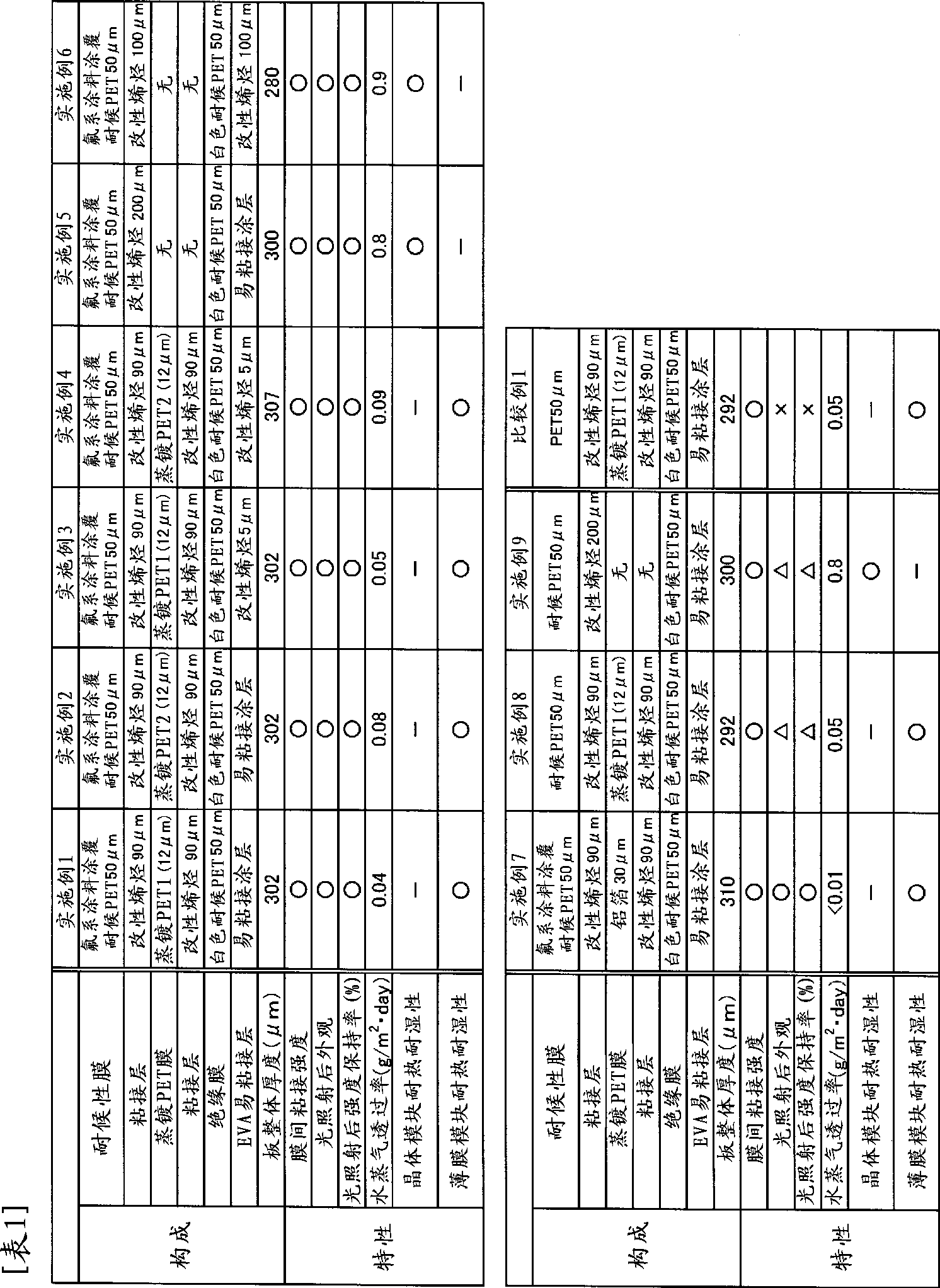

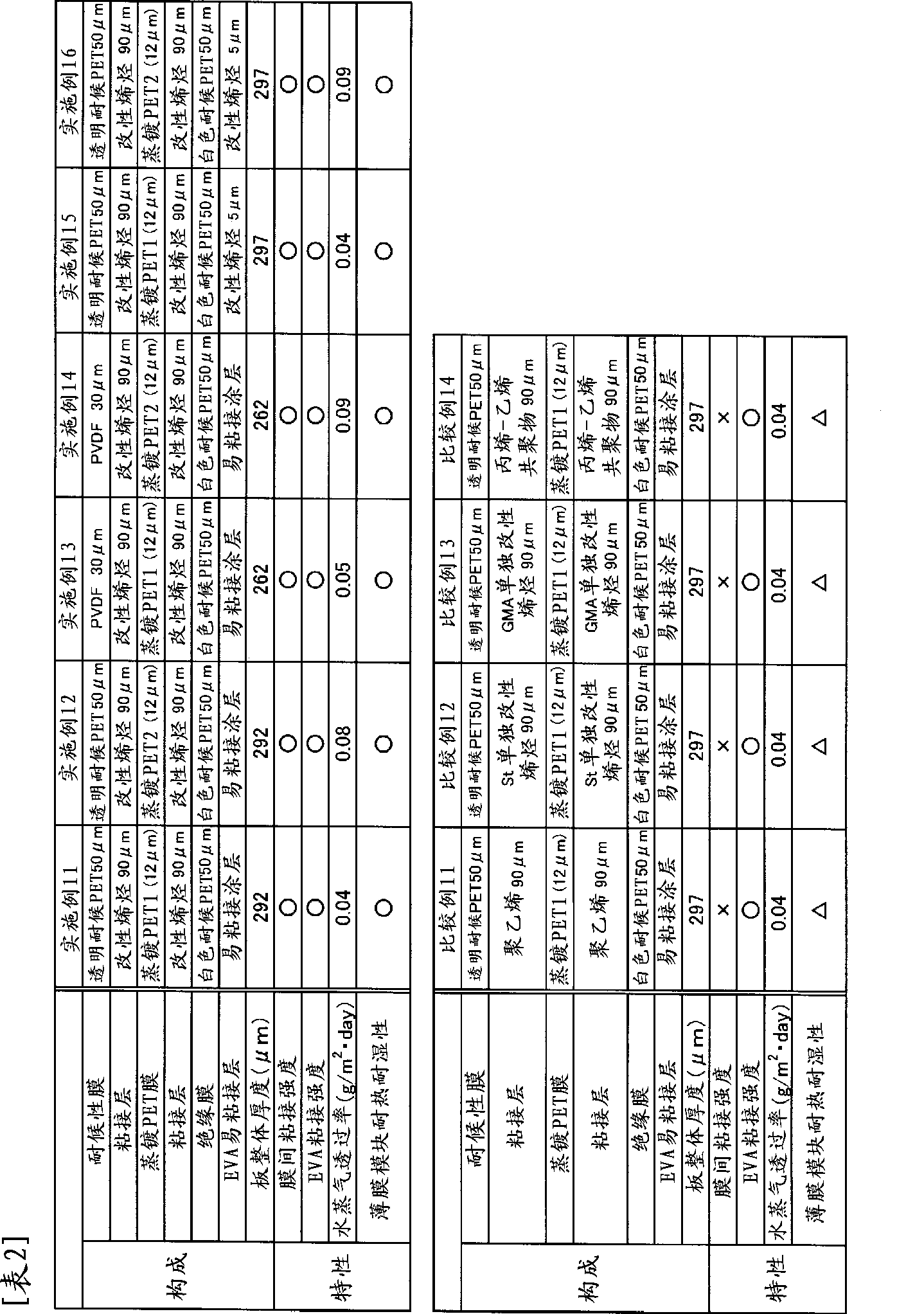

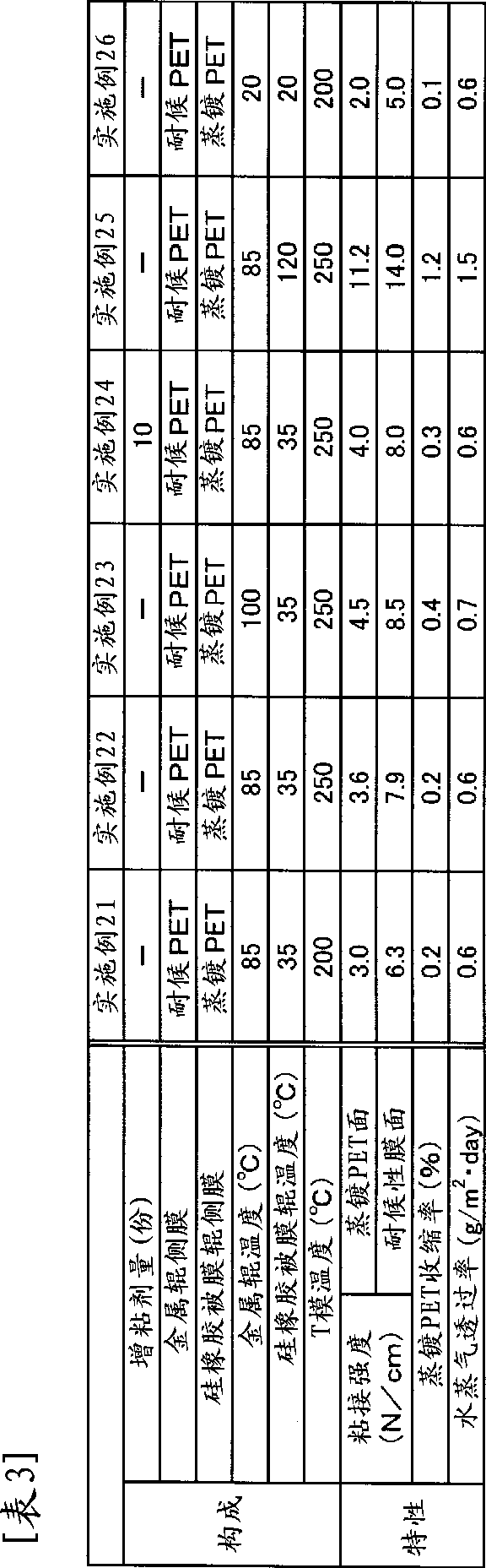

[0177] The first embodiment of the present invention consists of a weather-resistant polyester resin film (first layer) / modified polyolefin resin layer (second layer) / evaporated polyester resin film (third layer) / modified Backsheet for solar cells with a five-layer structure consisting of polyolefin resin layer (fourth layer) / weather-resistant polyester resin film (fifth layer). Solar cells are arranged on the fifth layer side. In this form, high water vapor barrier properties can be ensured by the presence of the third layer.

[0178] It is preferable to further apply a fluorine-based paint to the outer surface (surface opposite to the second layer) of the weather-resistant polyester resin film of the first layer to improve weather resistance.

[0179] In order to improve the adhesiveness with the sealing material of the solar cell element, it is preferable to further provide an undercoat layer on the outer surface (the surface opposite to the fourth layer) of the weather-re...

no. 2 approach )

[0185] The second embodiment of the present invention is a three-dimensional structure consisting of a weather-resistant polyester resin film (first layer) / modified polyolefin resin layer (second layer) / weather-resistant polyester resin film (third layer). Layer structure backsheet for solar cells. Solar cells are arranged on the third layer side.

[0186] It is preferable to further apply a fluorine-based paint to the outer surface (surface opposite to the second layer) of the weather-resistant polyester resin film of the first layer to improve weather resistance.

[0187] In order to improve the adhesiveness with the sealing material of the solar cell element, it is preferable to further provide a primer layer on the outer surface (the surface opposite to the second layer) of the weather-resistant polyester resin film of the third layer.

[0188] It is preferable to mix a white pigment in the third layer so that sunlight can be reflected.

[0189] In this embodiment, it is...

no. 3 approach )

[0192] The third embodiment of the present invention is a resin layer (third layer) composed of weather-resistant polyester resin film (first layer) / modified polyolefin resin layer (second layer) / unmodified polyolefin resin component. layer) / modified polyolefin-based resin layer (fourth layer) is a four-layer back sheet for solar cells. In this embodiment, the second layer, the third layer, and the fourth layer are formed of an olefin-based resin, so the water vapor barrier properties required as a solar battery back sheet can be ensured.

[0193] The solar cell element is placed in direct contact with the surface of the fourth layer. In this case, there is no need to arrange a sealing material for sealing the solar cell element between the solar cell element and the fourth layer. The fourth layer functions as a sealing material for the solar cell element. That is, the back sheet for solar cells of this aspect has a function not only as a back sheet but also as a sealing mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com