Process for preparing effective components of schisandrachinensis

A preparation process and technology of effective parts, applied in the field of continuous preparation of schisandra lignans, can solve the problems of unclear health effects, crossed effective parts, low extraction efficiency, etc., to improve human immunity, improve sleep, and avoid waste of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

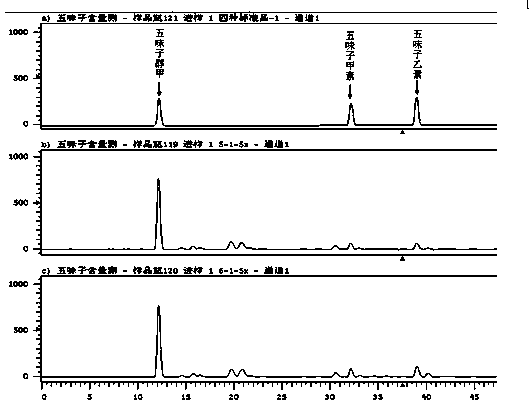

[0015] The dried mature fruit of Schisandra chinensis was crushed to 50 mesh, placed in supercritical CO 2 In the extraction device, the pressure of the extraction kettle: 35MPa, the temperature: 45°C, the flow rate: 8L / min; the pressure of the separation kettle: 4.5MPa, the temperature: 30°C, and the extraction was carried out for 6 hours to obtain supercritical oil of Schisandra chinensis, and the yield of the oil was 14.2 %. This part mainly contains unsaturated fatty acids, lignans and volatile oil components; the determination conditions of lignans are reversed high performance liquid chromatography, and the chromatographic conditions are acetonitrile / water gradient elution (see Table 1 for details), and the flow rate is: 1.0ml / min, column temperature 30℃, chromatographic column: PLATISIL ODS column (250mm×4.6mm, 5μm); detection wavelength 250nm, the standard used is schisandrin A, schisandrin A and schisandrin B, three kinds of oil The sum of the component contents is 1...

example 2

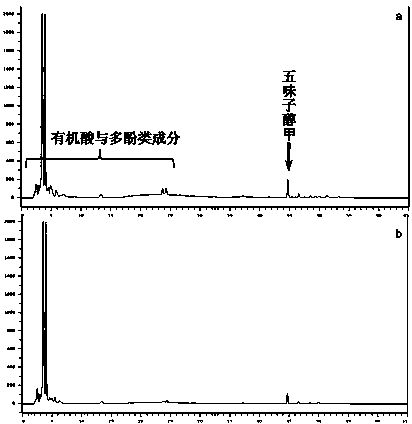

[0023] (1) Grind the dried and mature fruits of Schisandra chinensis to 40 mesh, and place them in supercritical CO 2 In the extraction device, the pressure of the extraction kettle: 25MPa, the temperature: 35℃, the flow rate: 4L / min; the pressure of the separation kettle: 3MPa, the temperature: 25℃, and the extraction was performed for 2 hours to obtain supercritical oil of Schisandra chinensis, which mainly contained unsaturated Fatty acid, lignan and volatile oil components, its content determination method is the same as example 1, and the chromatogram sees figure 1 (b), the results showed that the oil yield was 8.25%, and the sum of the three lignan contents was 12.1%.

[0024] (2) Add 5 times the amount of 30% ethanol to the dry residue at 25°C, stir and extract once, each extraction time: 4 hours, then filter with 6 layers of gauze, suction filter the filtrate, and extract the obtained clear filtrate Concentrate under reduced pressure to make a thick extract, dry the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com