Silver powder for printing size for solar cell electrodes and preparation process thereof

A technology of solar cells and silver powder, which is applied in the field of solar cells, can solve the problems of difficult effective transmission of current and low photoelectric conversion efficiency, and achieve the effects of good filling characteristics and electrical properties, high photoelectric conversion efficiency, and high dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

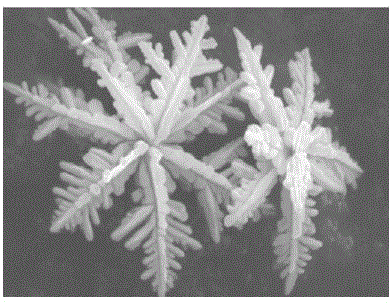

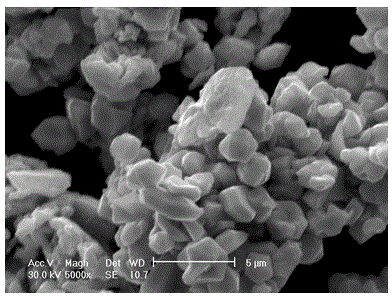

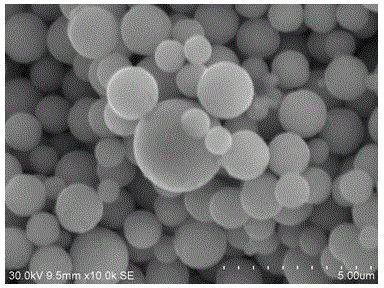

Image

Examples

Embodiment 1

[0024] A. Prepare respectively the silver nitrate solution that is 0.5mol / L and the ascorbic acid solution that concentration is 0.5mol / L with deionized water;

[0025] B. Get 1% polyvinylpyrrolidone of the silver nitrate quality, add in the silver nitrate solution obtained in step A, and disperse for 5 minutes with a rotating speed of 450r / min under ultrasonic conditions, then adjust the pH of the mixed solution with dilute nitric acid to be 2, and obtain Silver precursor solution;

[0026] C. Get 1% polyvinylpyrrolidone of reducing agent quality, add in the reducing agent solution obtained in step A, obtain reducing mixed solution;

[0027] D. According to the molar ratio of reducing agent:silver nitrate=1:1, the silver precursor solution obtained in step B is gradually added dropwise to the reduction mixed solution obtained in step C for reaction, then left to stand, and then the liquid and solid are separated, and then the The solid was washed three times with deioniz...

Embodiment 2

[0029] A. Prepare respectively the silver nitrate solution that concentration is 1.5mol / L and the glucose solution that concentration is 0.6mol / L with deionized water;

[0030] B. Get 2.5% Tween of the silver nitrate mass, add it in the silver nitrate solution obtained in step A, and disperse for 5 minutes with a rotating speed of 500r / min under ultrasonic conditions, then adjust the pH of the mixed solution with dilute nitric acid to be 4 to obtain silver nitrate Precursor solution;

[0031] C. Take 2.5% Tween of reducing agent quality, add in the reducing agent solution obtained in step A, obtain reducing mixed solution;

[0032] D. According to the molar ratio of reducing agent:silver nitrate=2:1, the silver precursor solution obtained in step B is gradually added dropwise to the reduction mixed solution obtained in step C for reaction, then left to stand, and then the liquid and solid are separated, and then The solid matter was washed 3 times with deionized water and...

Embodiment 3

[0034] A. Prepare the silver nitrate solution that is 2mol / L and the triethanolamine solution that concentration is 0.7mol / L with deionized water respectively;

[0035] B. Get the polyethylene glycol of 5% of silver nitrate quality, add in the silver nitrate solution gained in step A, and under the condition of ultrasonic wave with rotating speed be that 600r / min carry out disperse for 5 minutes, then adjust the pH of mixed solution with dilute nitric acid to be 6, Obtain silver precursor solution;

[0036] C. Get 5% polyethylene glycol of reducing agent quality, add in the reducing agent solution obtained in step A, obtain reducing mixed solution;

[0037] D. According to the molar ratio of reducing agent: silver nitrate = 4: 1, the silver precursor solution obtained in step B is gradually added dropwise to the reduction mixed solution obtained in step C for reaction, then left to stand, and then the liquid and solid are separated, and then the The solid matter was washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com