Modified graphene EPS particles, preparation method of mortar and modified graphene EPS mortar

A graphene and modified technology, applied in the field of mortar preparation, modified graphene EPS mortar, and modified graphene EPS particles, can solve the problem of high thermal conductivity, compressive and flexural strength, low shrinkage crack resistance, thermal insulation Insufficient thermal insulation effect, etc., to achieve the effect of large specific surface area, improved shrinkage crack resistance, and improved microscopic morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

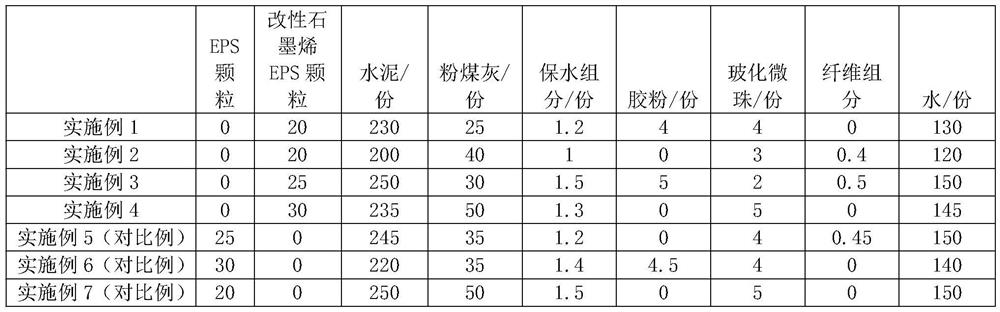

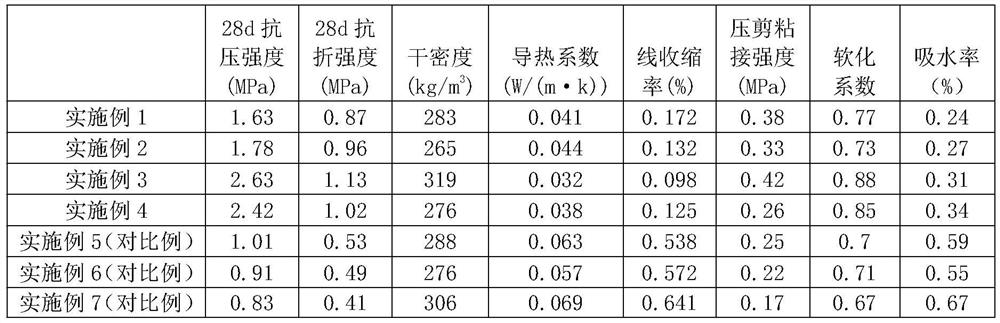

[0030] The present invention will be further described below in conjunction with the examples. The materials in this example are not particularly specified, and they are all commercially available conventional building materials.

[0031] Modified graphene EPS particle of the present invention is prepared by following method:

[0032] The specific operation is to use 5% sodium borohydride to reduce the carboxyl and carbonyl groups around the 10% graphene sheet, and then fully react with 30% alkylbenzenesulfonic acid in an ice bath , successfully grafted sulfonic acid groups onto the graphene oxide sheet, and then reduced it with hydrazine with a mass ratio of 40% at 100°C to obtain sheet-modified graphene, and then combined it with styrene monomer , using a suspension polymerization method to polymerize polystyrene particles, and then polymerize and foam with n-pentane with a mass ratio of 15% at normal pressure 100°C to obtain graphene-modified polystyrene foam particles, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com