Combined type biochar enhanced nitrogen removal filler and preparation method thereof

A bio-carbon, combined technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of ammonia fiber bursting, less research on rice husk pretreatment, etc. The effect of nitrogen performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

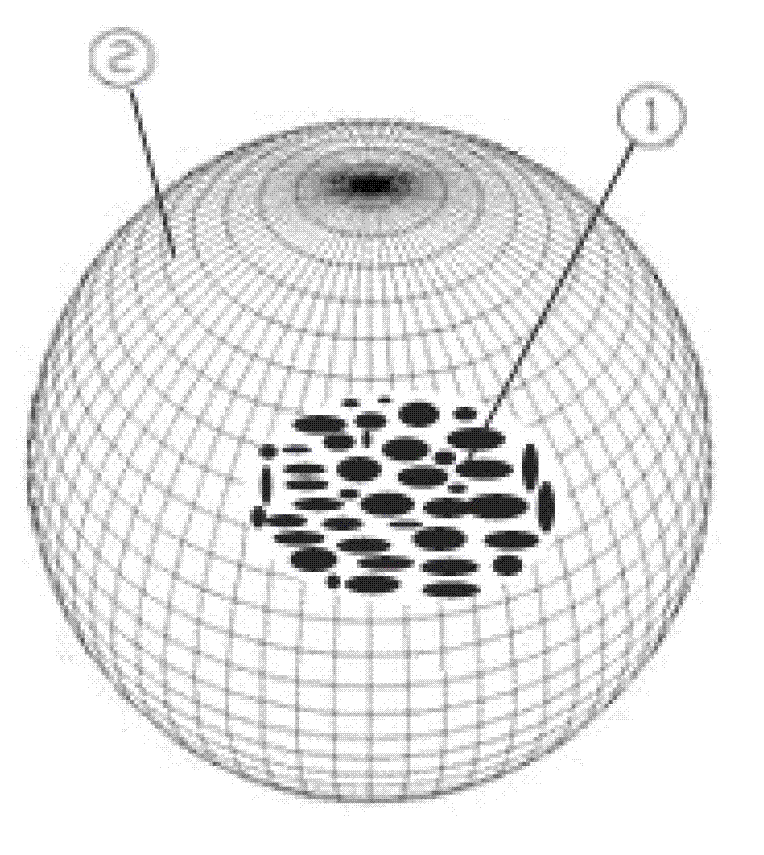

[0062] A combined biological carbon-enhanced denitrification filler, comprising: a mesh suspension ball 1 filled with modified rice husks 2, so that the modified rice hulls occupy 60% of the inner space of the mesh suspension ball 1, and the mesh suspension The mesh aperture of the ball 1 is 2-3mm, and the modified rice husk 2 is the rice husk processed by the following treatment method, and the treatment method is:

[0063] According to the ratio of solid-liquid mass volume ratio of 1:100 g / liter, rice husks are put into water, and then H 2 o 2 Make H 2 o 2 The mass volume ratio concentration is controlled at 15-20g / L, then use HCl or H 2 SO 4 will join H 2 o 2 After the liquid pH is adjusted to 2-3, then add FeSO 4 and FeSO 4 The mass volume ratio concentration is controlled at 2-3g / L, continuously stirred with a stirrer at 100r / min, and reacted for 1.5-2h. After taking out the rice husk and washing it with water for 3 times, put it in a 60°C oven for drying to obtai...

Embodiment 2

[0066] A method for preparing a combined biochar-enhanced denitrification filler, which comprises taking rice husks and mesh suspension balls 1 with a mesh aperture of 2-3 mm, then modifying the rice husks, and then filling the modified rice husks 2 Enter the mesh suspension ball 1, and make the modified rice husk occupy 60% of the space in the mesh suspension ball 1, the following methods are adopted for the modification of the rice husk:

[0067] According to the ratio of solid-liquid mass volume ratio of 1:100 g / liter, rice husks are put into water, and then H 2 o 2 Make H 2 o 2 The mass volume ratio concentration is controlled at 15-20g / L, then use HCl or H 2 SO 4 will join H 2 o 2 After the liquid pH is adjusted to 2-3, then add FeSO 4 and FeSO 4 The mass volume ratio concentration is controlled at 2-3g / L, continuously stirred with a stirrer at 100r / min, and reacted for 1.5-2h. After taking out the rice husk and washing it with water for 3 times, put it in a 60°C ...

example

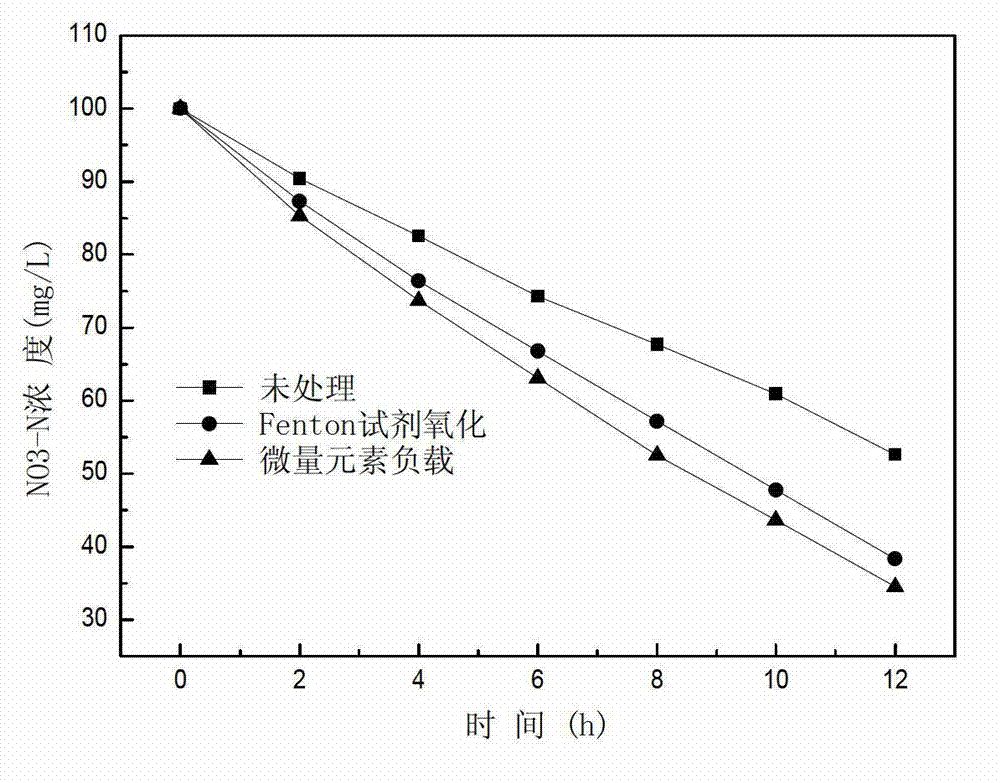

[0070] Combined biological carbon enhanced denitrification filler, where "biological carbon" refers to rice husk (after pretreatment), and "combination" means the combination of rice husk and suspended balls. The filler composed of the two can strengthen biological denitrification in sewage treatment, reduce membrane fouling in membrane bioreactors, increase water flux, and is also a resource utilization of agricultural organic solid waste (rice husk).

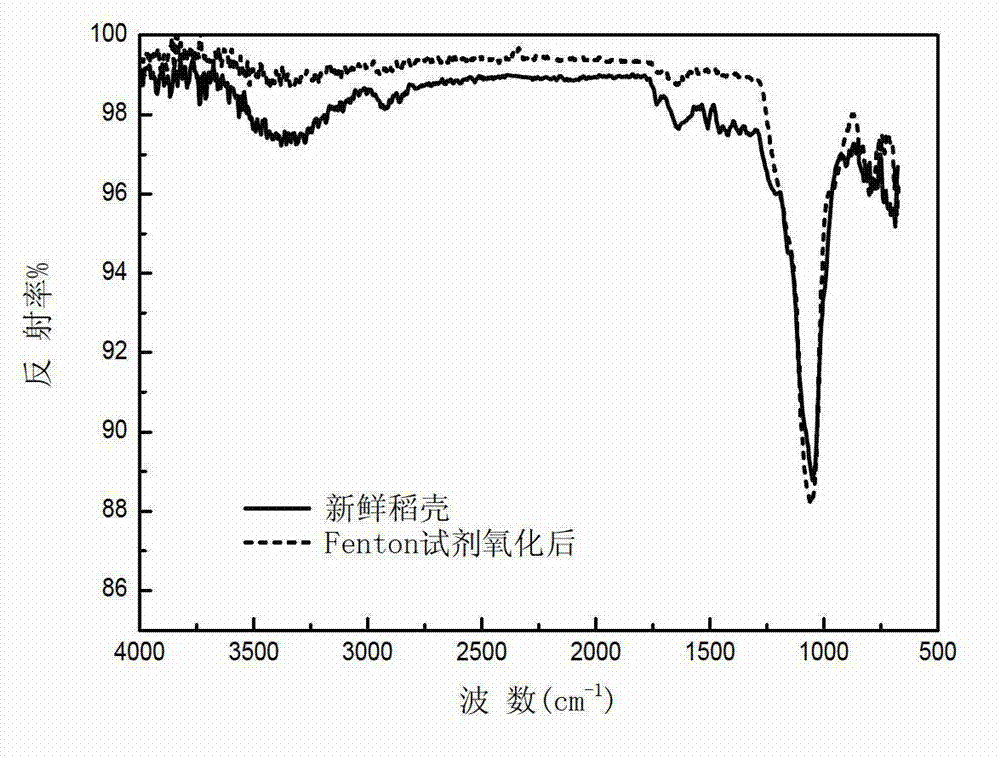

[0071] The core of the present invention is the pretreatment of rice husks, and the comprehensive pretreatment method adopted is: steam explosion + Fenton reagent oxidation + trace element loading, wherein both the Fenton reagent oxidation and trace element loading methods are used for the first time. Figure 4 It is the pretreatment flowchart of rice husk, and the specific method is as follows:

[0072] 1) Steam explosion

[0073]Steam explosion is a pretreatment method that uses saturated water vapor to heat raw materials, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com