Constructed wetland for treating sewage with low carbon nitrogen ratio by utilizing ores

A technology of low carbon-to-nitrogen ratio and constructed wetland, applied in the field of water treatment, can solve the problems of poor microbial denitrification effect, easy to reach adsorption saturation, and decline in treatment efficiency, and achieve the effects of convenient management, low investment and operation costs, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

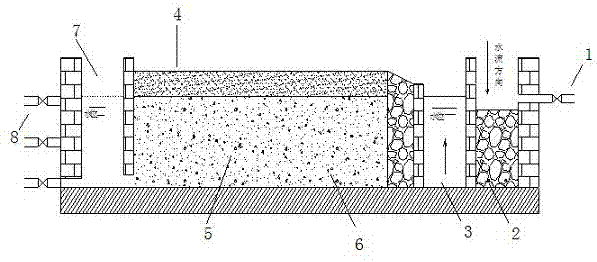

[0035] Such as figure 1 As shown, a constructed wetland using minerals to treat sewage with a low carbon-nitrogen ratio first establishes a constructed wetland pool with a size of 5.64m×1.48m×1m (L×W×H). The body of the wetland pool is built with bricks, and a layer of concrete is laid on the bottom to prevent leakage. The constructed wetland pool includes a water inlet pipe 1, a water inlet area 2, a water outlet area 7 and an outlet pipe 8. The water inlet pipe 1 is connected to the water inlet area 2; there can be 2-5 outlet pipes 8, and 3 are preferably selected in this embodiment. The heights of the three water outlet pipes 8 are different, and they are arranged sequentially from high to low. The height of the water level can be adjusted, and the submerged depth of the filler can be changed, so as to adjust the ratio of the aerobic zone and the anoxic zone, and improve the denitrification efficiency. The water outlet pipe 8 is connected to the water outlet area 7; the ...

Embodiment 2

[0040] Same as embodiment 1, the difference is that the backwashing pipe 5 is also included inside the packing area 6, and the backwashing pipe 5 is arranged in the horizontal direction and the vertical direction of the packing area 6, and the backwashing pipe 5 is equidistantly provided with outlet holes. The thickness of the limestone inside the water intake area 2 is 0.7m; the volume ratio of pyrite and limestone filled in the filling area 6 is 5:1, and the height of the filling area is 0.8m; the reed planting density is 10 plants / m 2 ; Outlet pipe 8 has 5. When the packing area 6 is blocked, the backwash pipe 5 can be opened to flush the inside of the packing area 6 . The heights of the five water outlet pipes 8 are different, and they are arranged in order from high to low. The height of the water level can be adjusted, and the submerged depth of the filler can be changed, so as to adjust the ratio of the aerobic zone and the anoxic zone, and improve the denitrification ...

Embodiment 3

[0042] Same as Example 1, the difference is that the inside of the filling area 6 also includes a backwash pipe 5; the thickness of the limestone inside the water inlet area 2 is 0.4m; the volume ratio of pyrite and limestone filled inside the filling area 6 is 1:1 , the height of filling area 6 is 0.5m; the planting density of reeds is 8 plants / m 2 ; Outlet pipe 8 has 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com