Refractory and thermal-insulating spray coating material and preparation method and application thereof

A technology of spraying coatings and refractory aggregates, which is applied in the field of refractory and heat-insulating spray coatings. It can solve the problems of high rebound rate, low bonding strength, and reduced heat dissipation on the surface of the furnace body when spraying refractory fibers, so as to improve mechanical properties and thermal shock stability. , Improve fire resistance and corrosion resistance, reduce surface temperature and heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A fire-resistant and heat-insulating spray coating, which includes two parts: a prefabricated slurry and a curing agent. The prefabricated slurry is prepared from refractory aggregates and binders. The percentage is: 61% refractory aggregate, 36% binder, 3% curing agent; wherein, the refractory aggregate consists of 56% alumina hollow spheres, 6% kyanite, 20% high alumina Clinker powder, 4% silica powder, 5% α-Al 2 o 3 Micropowder, 4%Cr 2 o 3 Micro powder, 5% polycrystalline alumina fiber composition.

[0048] The binder is composed of 74.8% aluminum dihydrogen phosphate solution, 25% water, 0.1% FS20 water reducing agent, and 0.1% chromic anhydride by weight percentage, wherein the weight percentage concentration of aluminum dihydrogen phosphate solution is 48% .

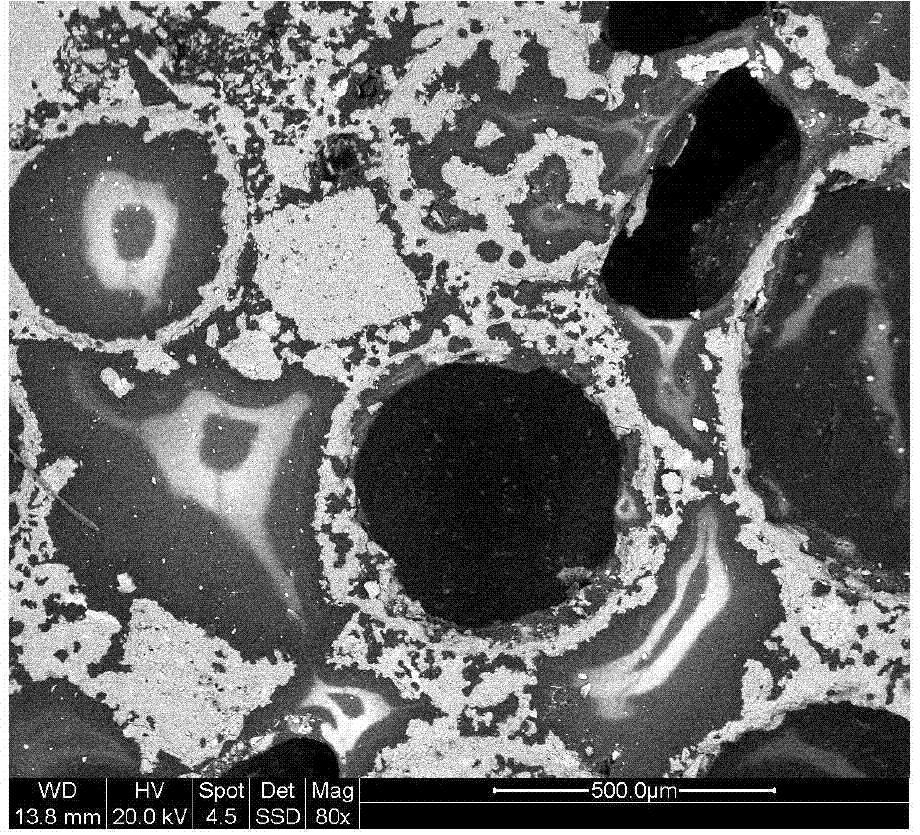

[0049] The same raw materials used in this example and the following examples are commercially available raw materials, wherein the alumina hollow spheres have a particle size of 1-0.1 mm, the kyanite p...

Embodiment 2

[0068] A fire-resistant and heat-insulating spray coating, which includes two parts: a prefabricated slurry and a curing agent. The prefabricated slurry is prepared from refractory aggregates and binders. The percentage is: 60% refractory aggregate, 34% binder, 6% curing agent; wherein, the refractory aggregate consists of 55% alumina hollow spheres, 7% kyanite, 20% high alumina Clinker powder, 4% silica powder, 5% α-Al 2 o 3 Micropowder, 3%Cr 2 o 3 Micro powder, 6% polycrystalline alumina fiber composition.

[0069] The binder is composed of 80% aluminum dihydrogen phosphate solution, 19.8% water, 0.05% FS20 water reducer, and 0.15% chromic anhydride by weight percentage, wherein the weight percentage concentration of aluminum dihydrogen phosphate solution is 48% .

[0070] The preparation method and application method of the fire-resistant and heat-insulating spray coating in this embodiment are the same as those in Embodiment 1.

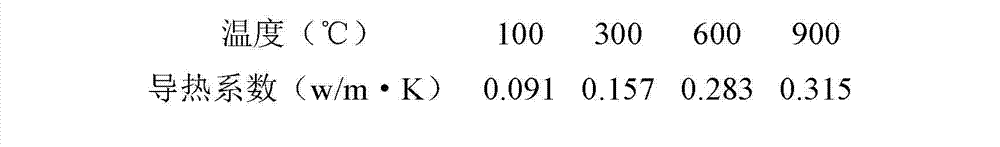

[0071] It can be seen from Table 3 an...

Embodiment 3

[0077] A fire-resistant and heat-insulating spray coating, which includes two parts: a prefabricated slurry and a curing agent. The prefabricated slurry is prepared from refractory aggregates and binders. The percentage is: 63% refractory aggregate, 34% binder, 3% curing agent; wherein, the refractory aggregate consists of 57% alumina hollow spheres, 6% kyanite, 20% high alumina Clinker powder, 4% silica powder, 5% α-Al 2 o 3 Micropowder, 3%Cr 2 o 3 Micro powder, 5% polycrystalline alumina fiber composition.

[0078] The binder is composed of 59.7% aluminum dihydrogen phosphate solution, 40% water, 0.15% FS20 water reducing agent, and 0.15% chromic anhydride by weight percentage, wherein the weight percentage concentration of aluminum dihydrogen phosphate solution is 48% .

[0079] The preparation method and application method of the fire-resistant and heat-insulating spray coating in this embodiment are the same as those in Embodiment 1.

[0080] It can be seen from Tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com