A kind of foamed ceramics produced by using ceramic pressing mud and its preparation method

A technology of foamed ceramics and pressed mud, applied in the field of foamed ceramics, can solve the problems of difficulty in stability, unfavorable performance of foamed ceramics, influence, etc., and achieve the effects of improving compressive strength, high utilization rate of tailings, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

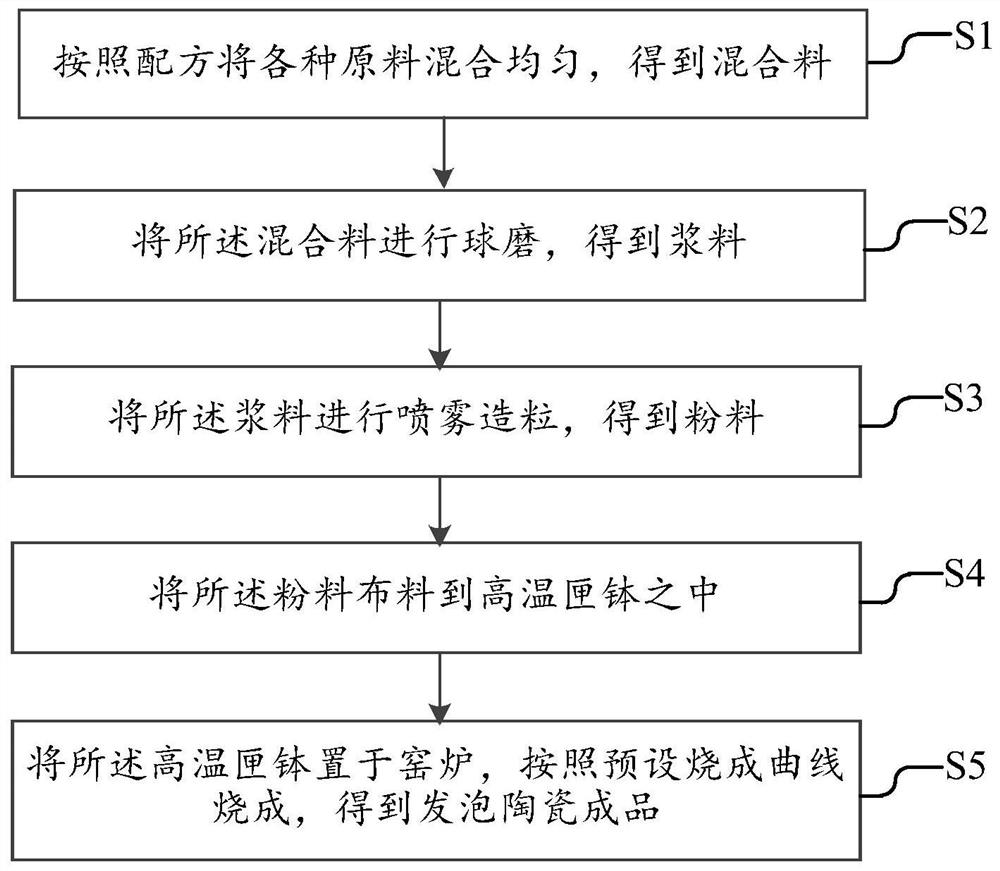

[0049] In order to improve the various properties of the foamed ceramics in the present invention, it is also necessary to cooperate with a specific preparation method. Specifically, refer to figure 1 , the preparation method of foam ceramics among the present invention comprises the following steps:

[0050] S1: Mix various raw materials evenly according to the formula to obtain a mixture;

[0051] S2: ball milling the mixture to obtain a slurry;

[0052] Wherein, the fineness of the slurry is 250 mesh sieve <0.5%.

[0053] S3: subjecting the slurry to spray granulation to obtain a powder;

[0054] Specifically, after the slurry is stale in the slurry tank for 24 to 48 hours, it is pumped to the spray tower for spray drying and granulation; in the powder obtained by granulation, the proportion of particles above 40 mesh is ≥ 20wt%. The powder has good fluidity, which is beneficial to the subsequent distributing process.

[0055] S4: distributing the powder into a high-tem...

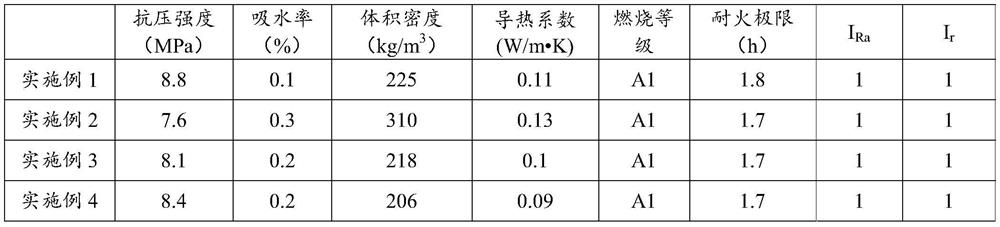

Embodiment 1

[0064] This embodiment provides a foamed ceramic, the formula of which is: 85 parts of Luoyuan red tailings, 6.5 parts of ceramic press mud, 3 parts of lithium china stone, 4 parts of black mud, 1.2 parts of silicon carbide, and 0.3 parts of manganese dioxide;

[0065] Among them, the ceramic press mud is composed of the following components: SiO 2 68.5%, Al 2 o 3 17.4%, Fe 2 o 3 0.6%, TiO 2 0.2%, CaO 3.7%, MgO 0.1%, K 2 O 4.4%, Na 2 O 3.6%, LOI 1.5%;

[0066] Its preparation method is:

[0067] (1) According to the formula, various raw materials are mixed uniformly to obtain a mixture;

[0068] (2) ball milling the mixture to obtain a slurry;

[0069] Wherein, the fineness of the slurry is 0.5% after sieving through a 250 mesh sieve.

[0070] (3) Spray granulating the slurry to obtain powder;

[0071] (4) distributing the powder into the high-temperature saggar;

[0072] (5) The high-temperature sagger is fired in a kiln to obtain a finished foamed ceramic prod...

Embodiment 2

[0075] This embodiment provides a foamed ceramic, the formula of which is: 87 parts of Luoyuan red tailings, 7.5 parts of ceramic pressing mud, 2 parts of lithium china stone, 2.2 parts of washed mud, 1 part of silicon carbide, and 0.3 parts of manganese dioxide;

[0076] Among them, the ceramic press mud is composed of the following components: SiO 2 68.5%, Al 2 o 3 17.4%, Fe 2 o 3 0.6%, TiO 2 0.2%, CaO 3.7%, MgO 0.1%, K 2 O 4.4%, Na 2 O 3.6%, LOI 1.5%;

[0077] Its preparation method is:

[0078] (1) According to the formula, various raw materials are mixed uniformly to obtain a mixture;

[0079] (2) ball milling the mixture to obtain a slurry;

[0080] Wherein, the fineness of the slurry is 0.5% with a 250-mesh sieve.

[0081] (3) Spray granulating the slurry to obtain powder;

[0082] (4) distributing the powder into the high-temperature saggar;

[0083] (5) The high-temperature sagger is fired in a kiln to obtain a finished foamed ceramic product.

[0084] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Combustion level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com