Method for preparing foamed ceramics

A technology for foaming ceramics and foaming agents, which is applied in the production of ceramic products, ceramic materials, clay products, etc., can solve the problems of difficulty in flexible adjustment, low utilization efficiency of tailings, and reduction in the amount of Luoyuanhong used, so as to reduce the bulk density and Thermal conductivity, improve overall utilization efficiency, and improve the effect of various performances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

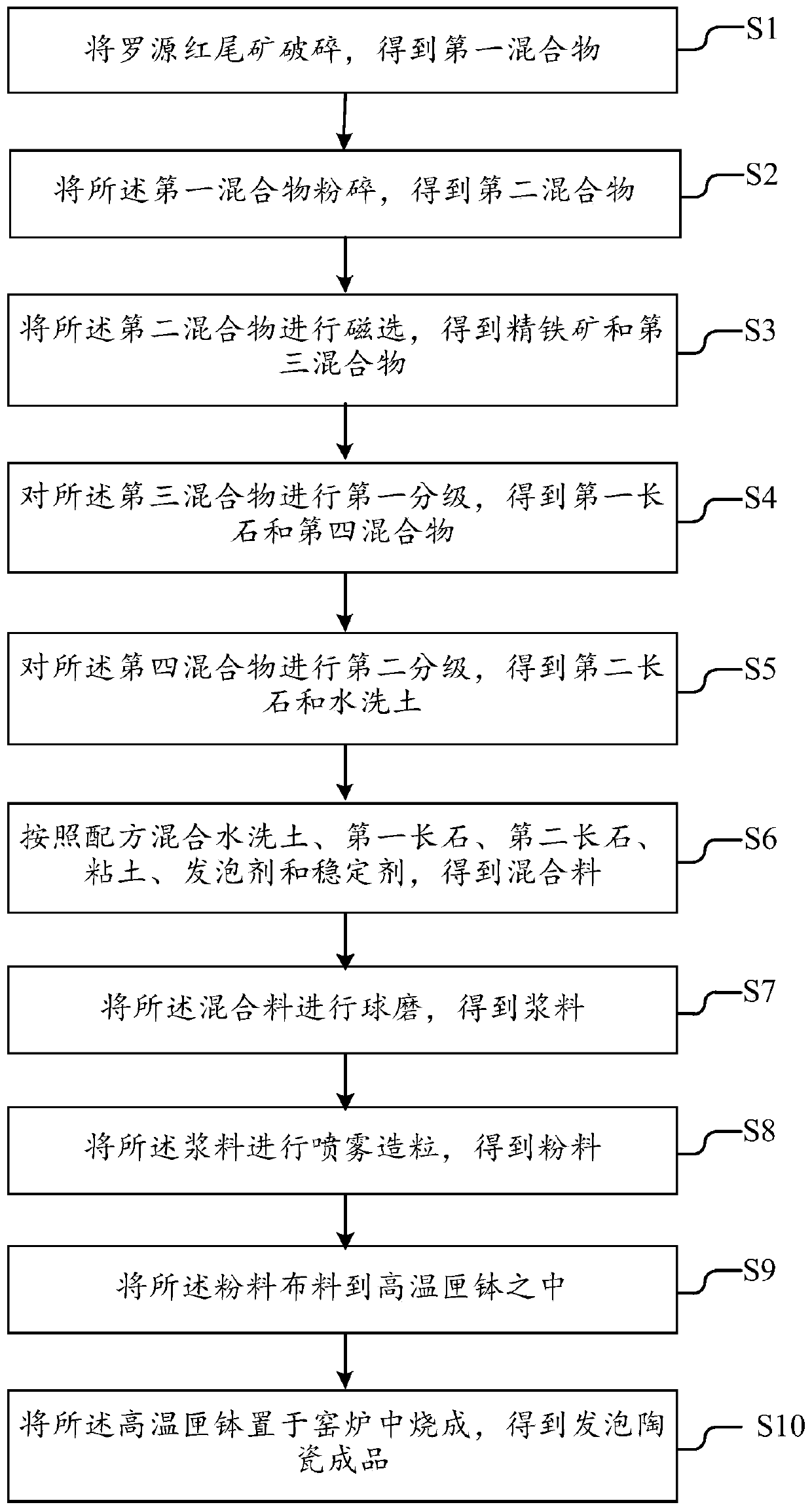

[0038] refer to figure 1 , the invention provides a kind of preparation method of foam ceramics, it comprises the following steps:

[0039] S1: Crushing the Luoyuan red tailings to obtain the first mixture;

[0040] Specifically, a jaw crusher or a cone crusher can be used to crush the Luoyuan red tailings; preferably, a cone crusher is used for coarse crushing. After coarse crushing, the particle size of the first mixture is 0.1-5 mm; preferably 0.1-3 mm.

[0041] S2: Pulverizing the first mixture to obtain a second mixture;

[0042] Wherein, the first mixture can be pulverized by using a ball mill or a roller mill; preferably, a ball mill is used. Further preferably, wet ball milling is used to pulverize the first mixture. The wet ball has low grinding energy and is suitable for grinding hard minerals. After pulverization, the particle diameter of the second mixture is 2-1000 μm. Preferably, the particle size of the second mixture is 2-800 μm. The second mixture slurr...

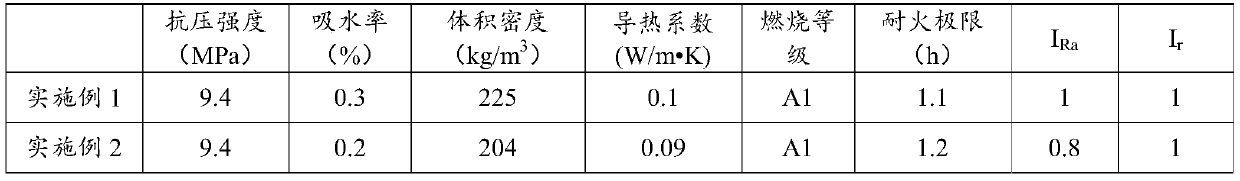

Embodiment 1

[0079] The present embodiment provides a kind of preparation method of foam ceramics, it comprises the following steps:

[0080] (1) crushing the Luoyuan red tailings to a particle size of ≤4mm to obtain the first mixture;

[0081] (2) ball milling the first mixture to a particle size of ≤800 μm to obtain a second mixture;

[0082] (3) Carrying out magnetic separation to the second mixture to obtain fine iron ore and the third mixture;

[0083] (4) wet sieving the third mixture to obtain the first feldspar and the fourth mixture with a particle size of 500-800 μm;

[0084] (5) subjecting the fourth mixture to hydrocyclone classification, controlling the overflow density to be 450-500 mesh, and obtaining the second feldspar and washed soil;

[0085] (6) Mix various raw materials according to the formula to obtain the mixture; wherein, the formula is: 25 parts of washed soil, 11 parts of the first feldspar, 55 parts of the second feldspar, 5 parts of sandbag soil, 3 parts of s...

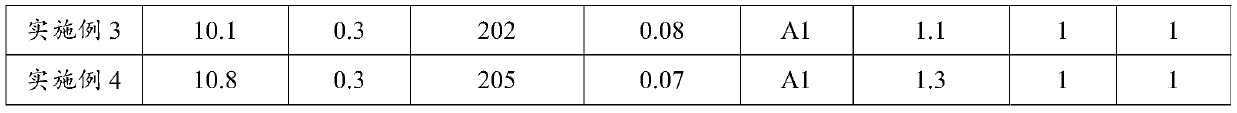

Embodiment 2

[0094] The present embodiment provides a kind of preparation method of foam ceramics, it comprises the following steps:

[0095] (1) Crushing the Luoyuan red tailings to a particle size of ≤3mm to obtain the first mixture;

[0096] (2) ball milling the first mixture to a particle size ≤ 850 μm to obtain a second mixture;

[0097] (3) Carrying out magnetic separation to the second mixture to obtain fine iron ore and the third mixture;

[0098] (4) wet sieving the third mixture to obtain the first feldspar and the fourth mixture with a particle size of 600-850 μm;

[0099] (5) The fourth mixture is subjected to hydrocyclone classification, and the overflow density is controlled to be 300-500 mesh, and the second feldspar and washed soil are obtained;

[0100] (6) Mix various raw materials according to the formula to obtain a compound; wherein, the formula is: 32 parts of washed soil, 11 parts of the first feldspar, 54 parts of the second feldspar, 2.2 parts of silicon carbide,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com