Preparation method and use of titanium catalyst for synthesis of polybutylene terephthalate

A polybutylene terephthalate and titanium-based catalyst technology, which is applied in the field of polyester synthesis, can solve the problems of reducing catalytic activity, affecting thermal stability of chips, melting stability, and long-term operation of devices, achieving The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

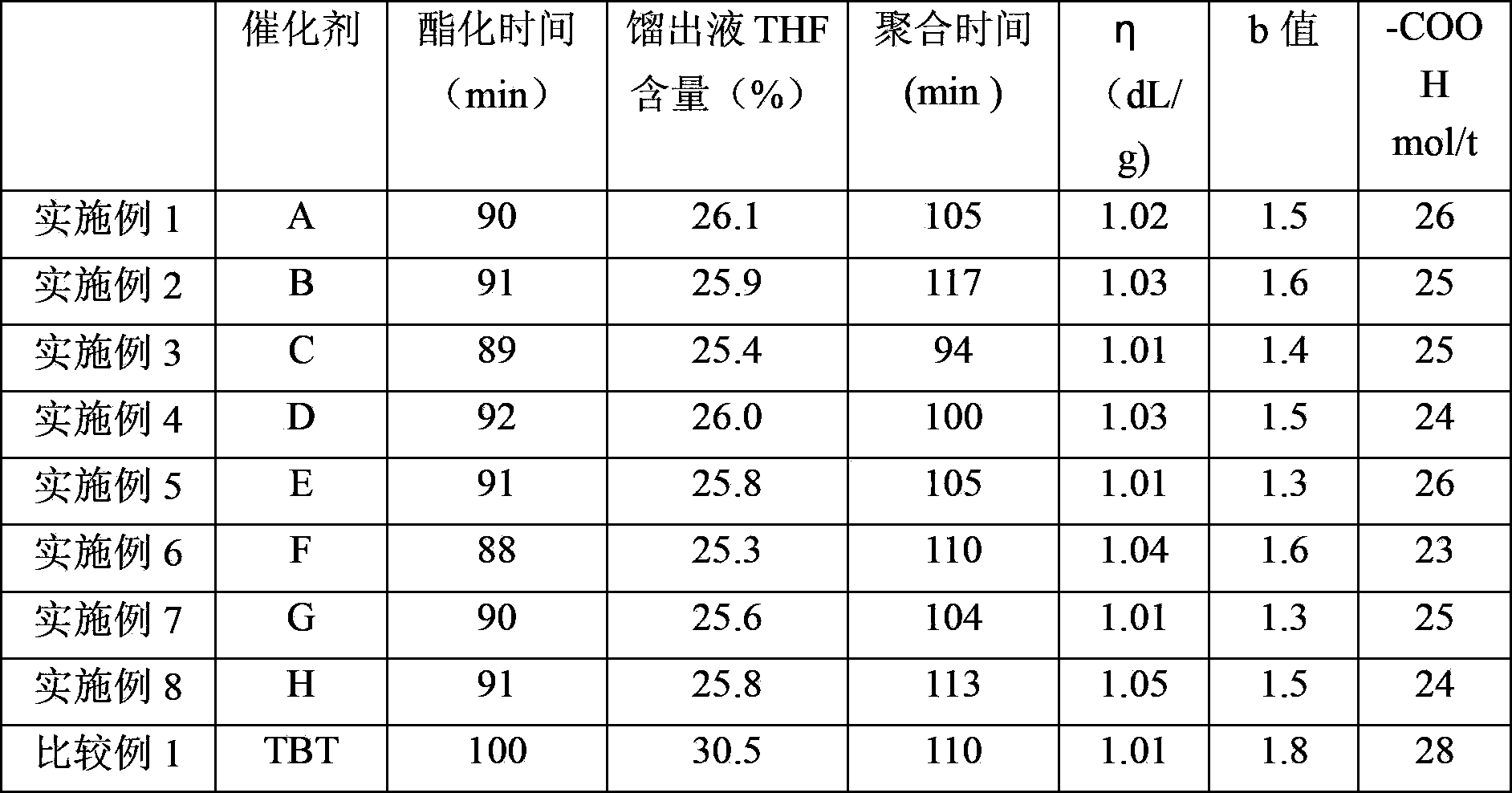

Examples

Embodiment 1

[0025] The molar ratio of tetraisopropyl titanate to glycerol is 1:0.5, the molar ratio of tetraisopropyl titanate to sodium hydroxide is 1:0.5, and the molar ratio of tetraisopropyl titanate to triethyl phosphate The molar ratio of tetraisopropyl titanate to the magnesium acetate tetrahydrate is 1:0.5, and the molar ratio of tetraisopropyl titanate to 1,4-butanediol solvent is 1:3.73.

[0026] Add 42.6g tetraisopropyl titanate (0.15mol) and 6.9g glycerol (0.075mol) and 50g 1,4-butanediol (0.56 mol), mix well. A solution of 3.0 g of sodium hydroxide (0.075 mol) and 50 g of deionized water was slowly dropped into the reactor, and after the addition was completed, the reaction was carried out at room temperature to 100° C. for 1 hour. Precipitate a white precipitate, continue to add 16.1g magnesium acetate tetrahydrate (0.075mol) and 13.7g triethyl phosphate (0.075mol), start to react at 50°C and gradually increase the temperature to 160°C for 3 hours, remove small molecules, t...

Embodiment 2

[0031] The molar ratio of tetrabutyl titanate to glycerol is 1:0.1, the molar ratio of tetrabutyl titanate to sodium hydroxide is 1:0.05, and the molar ratio of tetrabutyl titanate to triethyl phosphate is 1: 10. The molar ratio of tetrabutyl titanate to the sodium acetate trihydrate is 1:10, and the molar ratio of tetrabutyl titanate to 1,4-butanediol solvent is 1:50.

[0032] Add 51.1g tetrabutyl titanate (0.15mol) and 1.4g glycerol (0.015mol) and 675g 1,4-butanediol (7.5mol) into the reactor equipped with stirrer, separatory funnel and condenser ),well mixed. A solution of 0.3 g of sodium hydroxide (0.0075 mol) and 50 g of deionized water was slowly dropped into the reactor, and after the addition was completed, the reaction was carried out at room temperature to 50° C. for 0.1 hour. Precipitate a white precipitate, continue to add 204.2g sodium acetate trihydrate (1.5mol) and 273.1g triethyl phosphate (1.5mol), start at 50°C and gradually raise the temperature to 200°C fo...

Embodiment 3

[0037] The molar ratio of tetraisopropyl titanate to glycerol is 1:20, the molar ratio of tetraisopropyl titanate to sodium carbonate is 1:5, and the molar ratio of tetraisopropyl titanate to trimethyl phosphate is 1:0.1, the molar ratio of tetraisopropyl titanate to the magnesium acetate tetrahydrate is 1:0.02, and the molar ratio of tetraisopropyl titanate to 1,4-butanediol solvent is 1:2.

[0038] Add 42.6g tetraisopropyl titanate (0.15mol) and 276.0g glycerol (3.0mol) and 27.0g 1,4-butanediol ( 0.30mol), mix well. A solution of 79.5 g of sodium carbonate (0.75 mol) and 100 g of deionized water was slowly dropped into the reactor, and after the addition was completed, the reaction was carried out at room temperature to 100° C. for 12 hours. Precipitate a white precipitate, continue to add 6.4g of magnesium acetate tetrahydrate (0.003mol) and 2.1g of trimethyl phosphate (0.015mol), at 50°C, gradually increase the temperature to 200°C for 0.1 hour, remove small molecules, un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com