Ionic liquid-type phosphate fire retardant and preparation method thereof

A technology of phosphate esters and ionic liquids, which is applied in chemical instruments and methods, bulk chemical production, organic chemistry, etc., and can solve problems such as poor compatibility with polymer matrix, degradation of mechanical properties of materials, poor thermal stability, etc. problems, to achieve good application prospects, superior charcoal performance, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

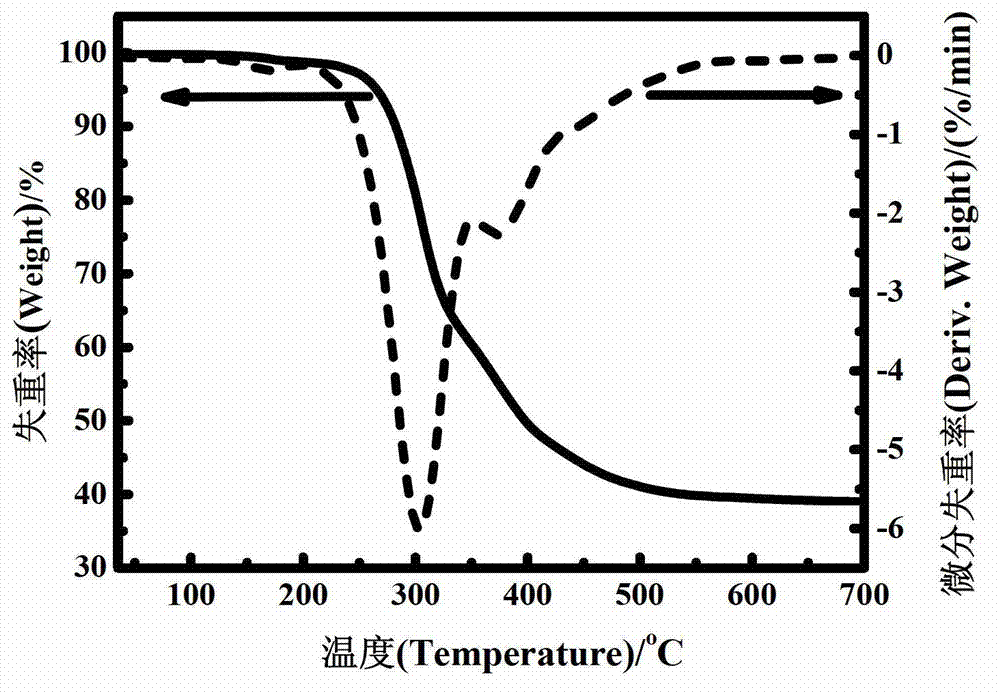

Embodiment 1

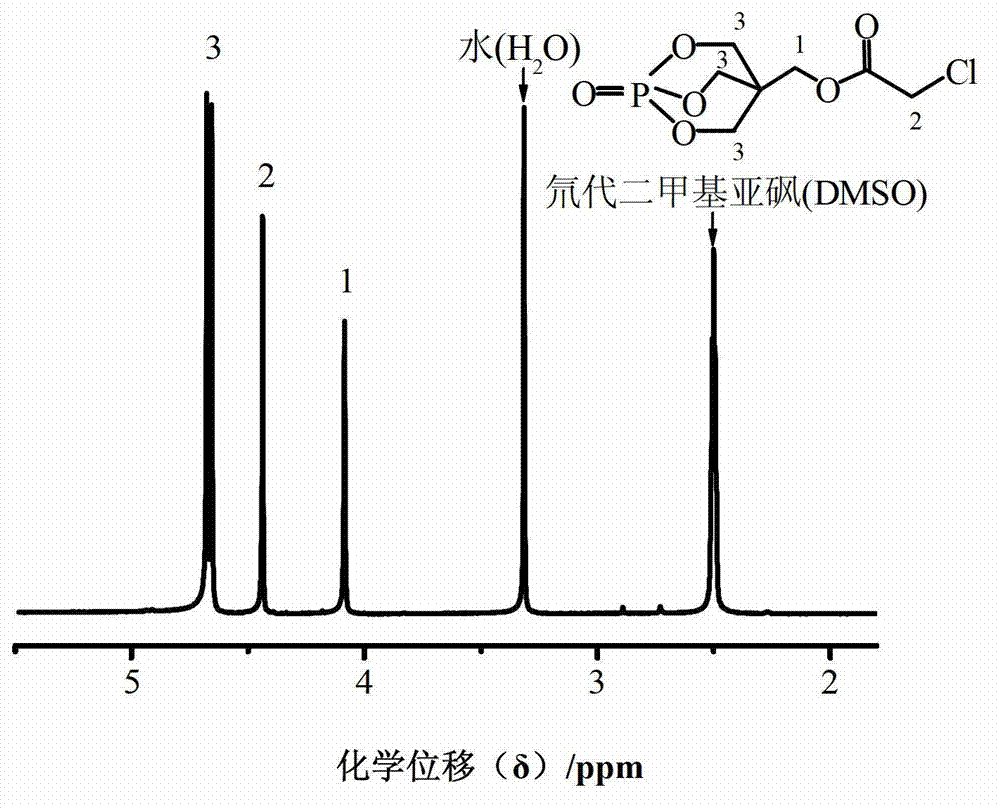

[0041] 1. Equipped with magnetic stirring, reflux condenser, dropping funnel and N 2 Add 27.01g (0.15mol) of PEPA and 100mL of acetonitrile to a 500mL three-necked flask with a ball, start stirring, and the reaction temperature rises to 40°C, then slowly add 33.89g (0.30mol) of chloroacetyl chloride dropwise within 1h, and wait After the addition of chloroacetyl chloride, the temperature was raised to 80°C to continue the reaction for 24h. After the reaction, the solvent was evaporated under reduced pressure, and then washed with deionized water and dried in a vacuum oven at 70°C for 12h to obtain intermediate I. The yield 79%.

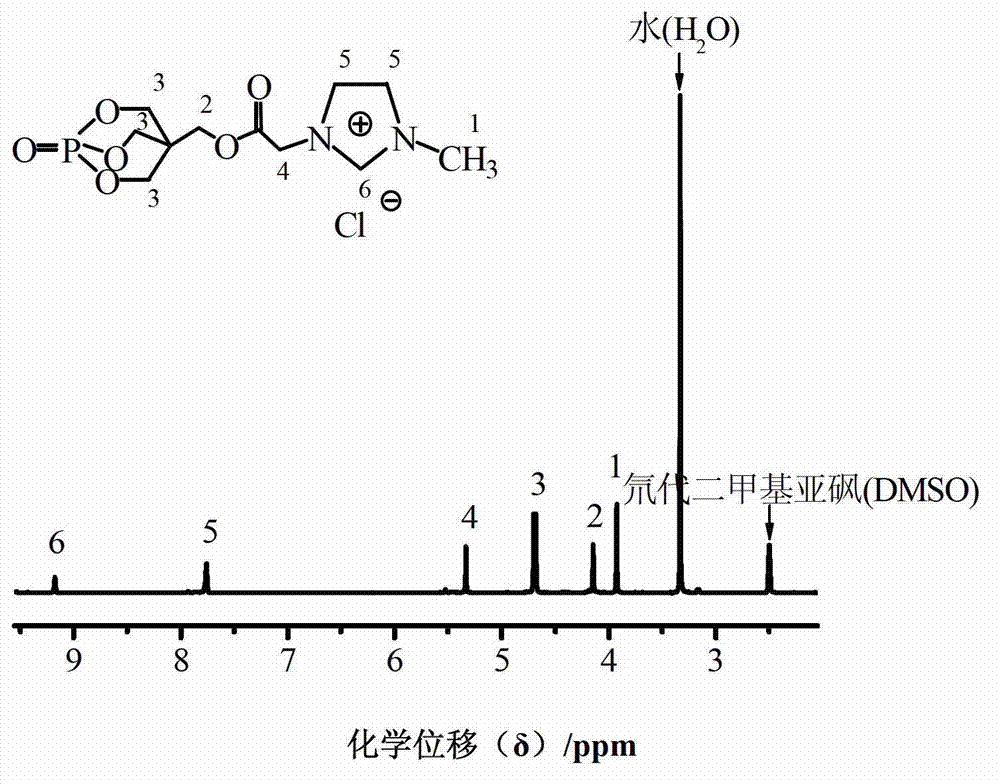

[0042] 2. Equipped with magnetic stirring, reflux condenser and N 2 Add 25.66g (0.15mol) of intermediate I, 9.85g (0.12mol) of 1-methylimidazole, and 100mL of acetonitrile into a 500mL three-neck flask with a ball, start stirring, heat up to 80°C for 24 hours, and filter after the reaction. The cake was washed with acetonitrile and dried in a vacuum...

Embodiment 2

[0046] 1. When equipped with N 2 In the 500mL flask of the ball, add 16.94g (0.05mol) anion as Cl - Ionic liquid phosphate flame retardant ([PCMIM]Cl), 6.59g (0.06mol) NaBF 4 and 100mL of acetonitrile, stirring and reacting at room temperature for 24h, filtering and concentrating the filtrate after the completion of the reaction, and drying in vacuum at 70°C for 12h to obtain the anion as BF 4 - The ionic liquid phosphate flame retardant (abbreviated as [PCMIM] BF 4 ), the structural formula is as follows:

[0047]

[0048] 2. Using ethanol as a solvent, the flame retardant [PCMIM]BF synthesized in step 1 4 Carry out wet compounding with APP at a mass ratio of 1:5, evaporate the solvent under reduced pressure, and dry in vacuum to obtain a composite flame retardant. Then the composite flame retardant is mixed with polypropylene (S1003) in an addition amount of 30wt% in a 175°C Huck torque rheometer at a speed of 30rpm for 10min to obtain a flame-retardant polypropylene...

Embodiment 3

[0050] 1. When equipped with N 2 In the 500mL flask of the ball, add 16.94g (0.05mol) anion as Cl - Ionic liquid phosphate flame retardant ([PCMIM]Cl), 11.04g (0.06mol) KPF 6 and 100mL of acetonitrile, stirring and reacting at room temperature for 24h, filtering and concentrating the filtrate after the reaction, drying in a vacuum oven at 70°C for 12h, and obtaining anion as PF 6 - The ionic liquid phosphate flame retardant (abbreviated as [PCMIM]PF 6 ), the structural formula is as follows:

[0051]

[0052] 2. Using ethanol as a solvent, the flame retardant [PCMIM]PF synthesized above was 6 Carry out wet compounding with APP at a mass ratio of 1:5, evaporate the solvent under reduced pressure, and dry in vacuum to obtain a composite flame retardant. Then the composite flame retardant is mixed with polypropylene (S1003) in an addition amount of 30wt% in a Hack torque rheometer at 175°C at a speed of 30rpm for 10min to obtain a flame-retardant polypropylene whose oxyge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com