Modified environment-friendly phenolic aldehyde thermal insulation material and preparation method thereof

A phenolic heat preservation and environmental protection technology, which is applied in the field of material preparation, can solve the problems of metal corrosion, low strength of phenolic foam heat preservation material, easy pulverization, etc., and achieve the effects of avoiding corrosion, reducing acidity and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

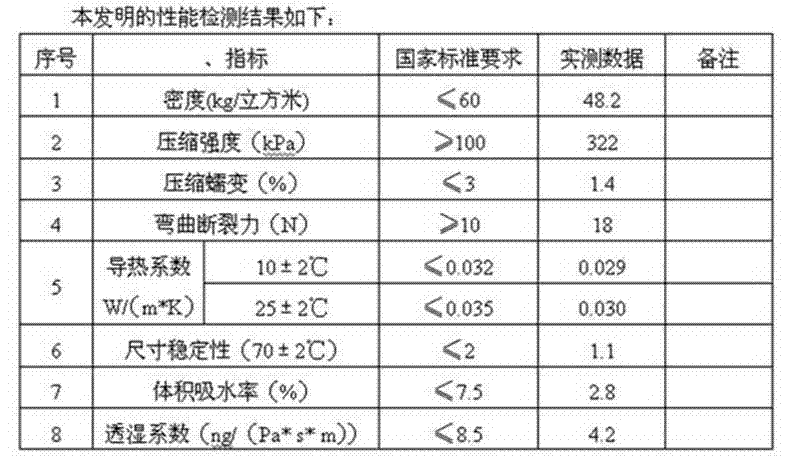

Image

Examples

Embodiment 1

[0044] Embodiment 1, this modified environment-friendly phenolic thermal insulation material, its raw material composition is as follows by weight ratio:

[0045] 100 parts of resole phenolic resin;

[0046] Sodium sulfite 10 parts;

[0047] 20 parts of phenolsulfonic acid solution;

[0048] 4 parts of stabilizer;

[0049] 2 parts of nanometer calcium carbonate;

[0050] 3 parts calcium sulfate whiskers;

[0051] 0.5 parts of nano aluminum hydroxide;

[0052] 0.5 parts of ethylene glycol;

[0053] Foaming agent 20 parts.

[0054]

Embodiment 2

[0055] Embodiment 2, this modified environment-friendly phenolic insulation material, its raw material composition is as follows by weight ratio:

[0056] 100 parts of resole phenolic resin;

[0057] Sodium sulfite 5 parts;

[0058] 10 parts of phenolsulfonic acid solution;

[0059] Stabilizer 2 parts;

[0060] 1 part of nanometer calcium carbonate;

[0061] Calcium sulfate whiskers 1 part;

[0062] 0.1 parts of nano aluminum hydroxide;

[0063] 0.1 part of ethylene glycol;

[0064] Foaming agent 15 parts.

[0065]

Embodiment 3

[0066] Embodiment 3, this modified environment-friendly phenolic insulation material, its raw material composition is as follows by weight ratio:

[0067] 100 parts of resole phenolic resin;

[0068] Sodium sulfite 15 parts;

[0069] 30 parts of phenolsulfonic acid solution;

[0070] 5 parts of stabilizer;

[0071] 8 parts of nanometer calcium carbonate;

[0072] Calcium sulfate whiskers 8 parts;

[0073] 3 parts of nano aluminum hydroxide;

[0074] 3 parts of ethylene glycol;

[0075] Foaming agent 30 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com