High-strength double-component laminating glue, and preparation method thereof

A two-component, jigsaw adhesive technology, applied in the direction of adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem that the strength and weather resistance cannot meet the use requirements, and the wet strength cannot meet the requirements , Adhesive strength is not high, to achieve excellent water resistance, high-pressure shear strength, simple preparation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

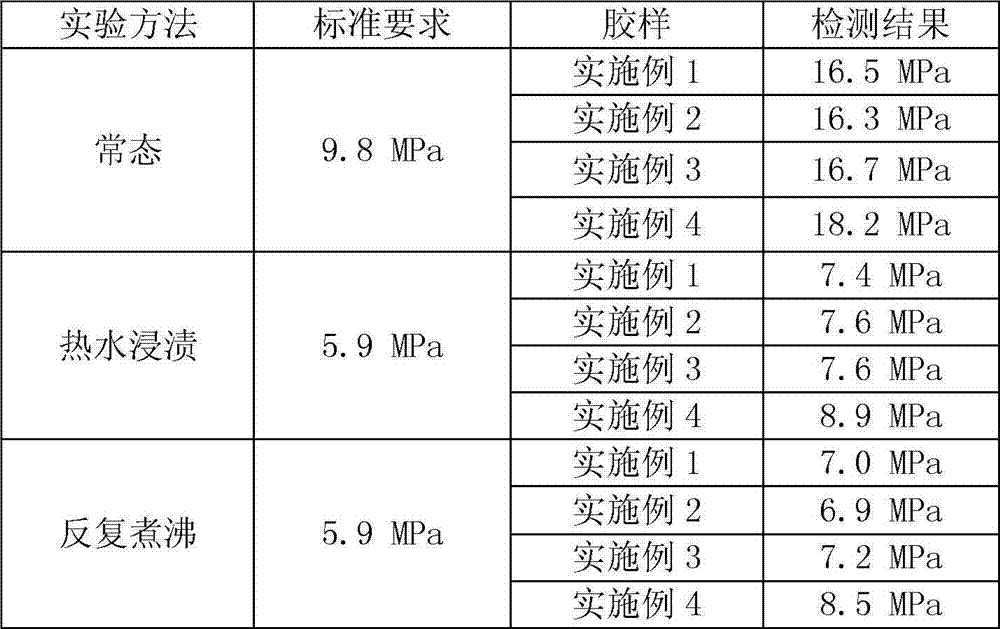

Examples

Embodiment 1

[0031] A high-strength two-component puzzle glue, which includes a main agent and a curing agent; the curing agent is polymethylene polyphenyl polyisocyanate, and the main agent components and specific proportions constitute:

[0032] Polyvinyl acetate emulsion 46.0g;

[0033] Polyvinyl alcohol 2088 3.5g;

[0034] Hydroxy-terminated polyether MN3050 3.0g;

[0035] Plasticizer BF988 1.0g;

[0036] Light calcium carbonate 20.0g;

[0037] Dispersant quick and easy 0.1g;

[0038] Defoamer FBX-02 0.1g;

[0039] Fungicide B50 0.1g;

[0040] Deionized water 26.2g;

[0041] The concrete steps of preparation method are as follows:

[0042] In the first step, 3.5g of polyvinyl alcohol 2088 was dissolved in 20.0g of deionized water at 85°C to make an aqueous solution of polyvinyl alcohol for use;

[0043] In the second step, add 46.0g of polyvinyl acetate emulsion, 3.0g of hydroxyl-terminated polyether MN3050, 0.1g of dispersant, and 0.1g of defoamer into the high-speed disperser...

Embodiment 2

[0046] A high-strength two-component puzzle glue, which includes a main agent and a curing agent; the curing agent is polymethylene polyphenyl polyisocyanate, and the main agent components and specific proportions constitute:

[0047] Polyvinyl acetate emulsion 46.0g;

[0048] Polyvinyl alcohol 2088 3.5g;

[0049] Amino-terminated polyether D2000 3.0g;

[0050] Plasticizer BF988 1.0g;

[0051] Ground calcium carbonate 20.0g;

[0052] Dispersant quick and easy 0.1g;

[0053] Defoamer FBX-02 0.1g;

[0054] Fungicide B50 0.1g;

[0055] Deionized water 26.2 g.

[0056] The concrete steps of preparation method are as follows:

[0057] In the first step, 3.5g of polyvinyl alcohol 2088 was dissolved in 20.0g of deionized water at 85°C to make an aqueous solution of polyvinyl alcohol for use;

[0058] In the second step, add 46.0g of polyvinyl acetate emulsion, 3.0g of amino-terminated polyether D2000, 0.1g of dispersant, and 0.1g of defoamer into the high-speed disperser in s...

Embodiment 3

[0061] A high-strength two-component puzzle glue, which includes a main agent and a curing agent; the curing agent is polymethylene polyphenyl polyisocyanate, and the main agent components and specific proportions constitute:

[0062] Ethylene-vinyl acetate copolymer emulsion 48.0g;

[0063] Polyvinyl alcohol 2088 3.5g;

[0064] Hydroxy-terminated polyether MN3050 3.0g;

[0065] Talc powder and kaolin 20.0g;

[0066]Dispersant quick and easy 0.1g;

[0067] Defoamer FBX-02 0.1g;

[0068] Fungicide B50 0.1g;

[0069] Deionized water 25.2 g.

[0070] The concrete steps of preparation method are as follows:

[0071] In the first step, 3.5g of polyvinyl alcohol 2088 was dissolved in 20.0g of deionized water at 85°C to make an aqueous solution of polyvinyl alcohol for use;

[0072] In the second step, add 48.0g of ethylene-vinyl acetate copolymer emulsion, 3.0g of hydroxyl-terminated polyether MN3050, 0.1g of dispersant, and 0.1g of defoamer into the high-speed disperser in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com