Integration method of high-sensitive temperature-controlled thin film hybrid integrated circuit

A technology of hybrid integrated circuits and integrated methods, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of integrated circuits, reduce thermal conduction resistance, improve long-term reliability, and broad market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] The FHTC30 temperature-controlled precision integrated power operational amplifier developed by Guizhou Zhenhua Scenery Semiconductor Co., Ltd. is mainly used in the fields of precision measurement and precision control for fast and precise processing and amplification of sensor signals. The typical working environment temperature is -100℃~200℃.

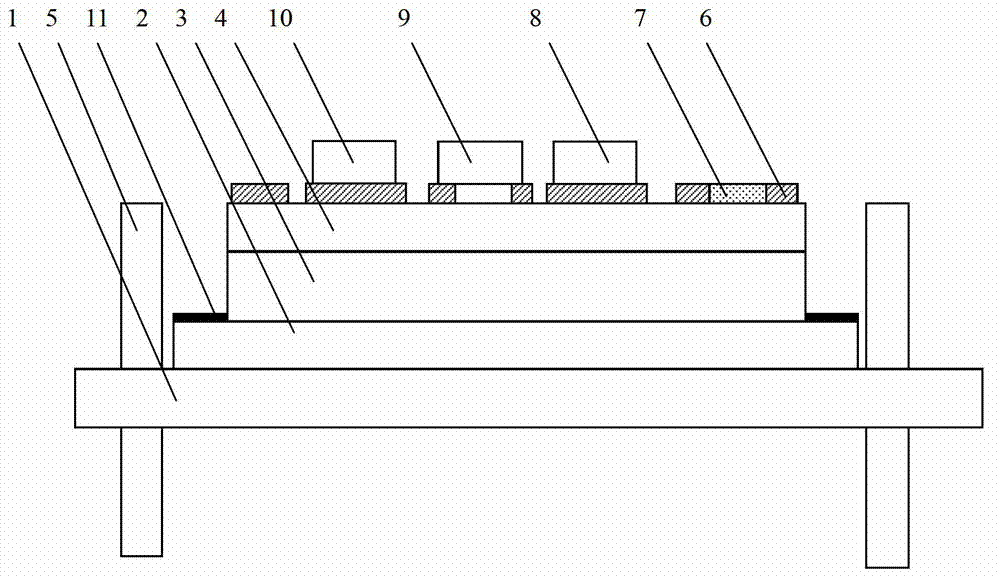

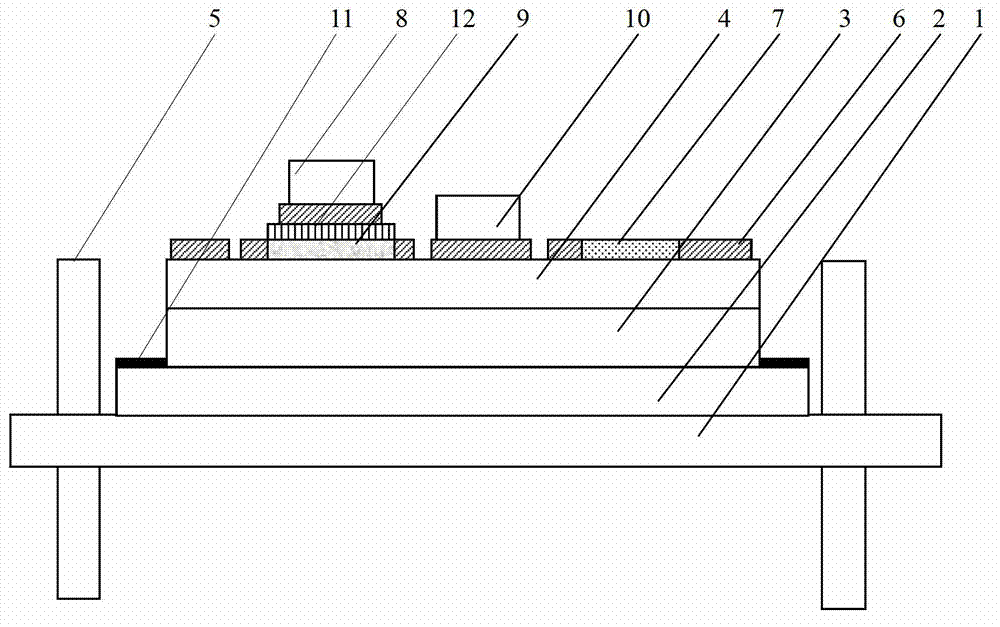

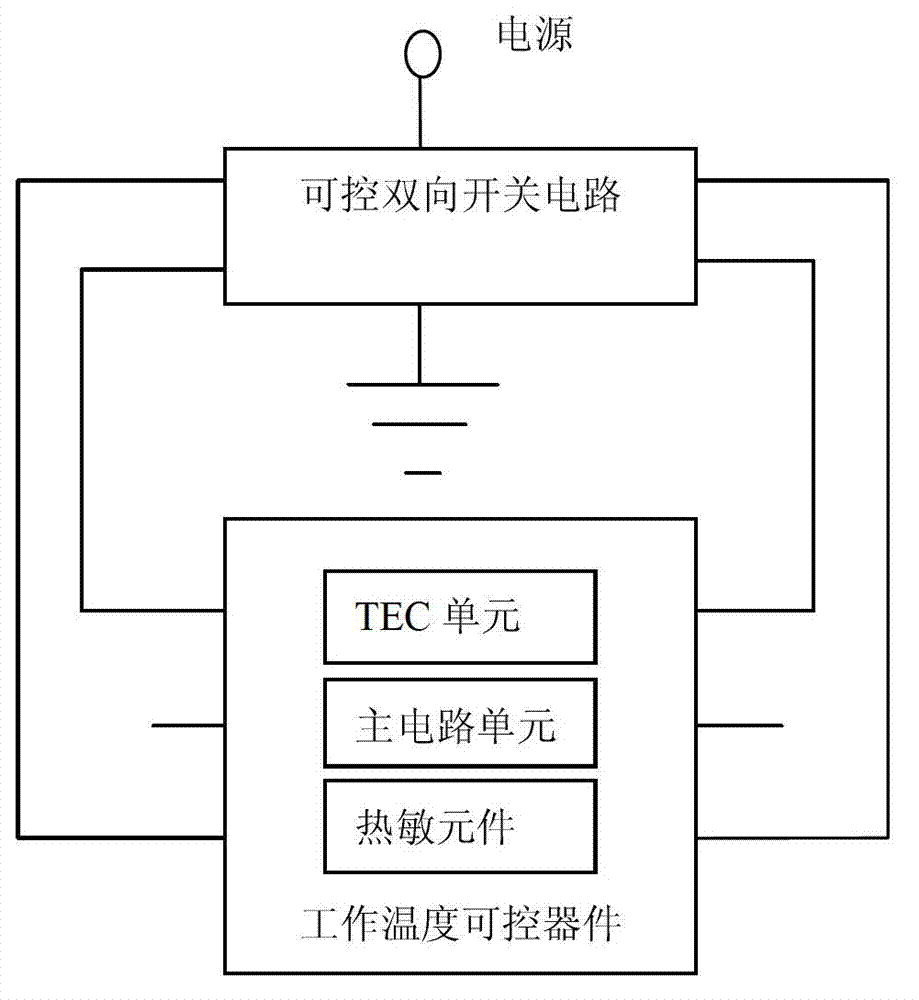

[0018] The core part of the device is a power operational amplifier chip (device main chip), a self-made thin film thermistor (for temperature control signal acquisition), a small power precision operational amplifier chip (for temperature control signal processing and amplification) ). Adopt the technology of the present invention—the integrated three-dimensional hybrid integration technology of the thin film thermistor and the main chip of the temperature control device. The specific process is as follows:

[0019] ⑴ Selection of ceramic substrate: In order to facilitate the rapid transfer of heat and match the thermal expa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com