A kind of direct sodium borohydride fuel cell anode and preparation method thereof

A fuel cell and sodium borohydride technology, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as poor binding force, low catalyst space utilization, and unstable electron conduction, achieving high conductivity and large practical space Utilization, the effect of good electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

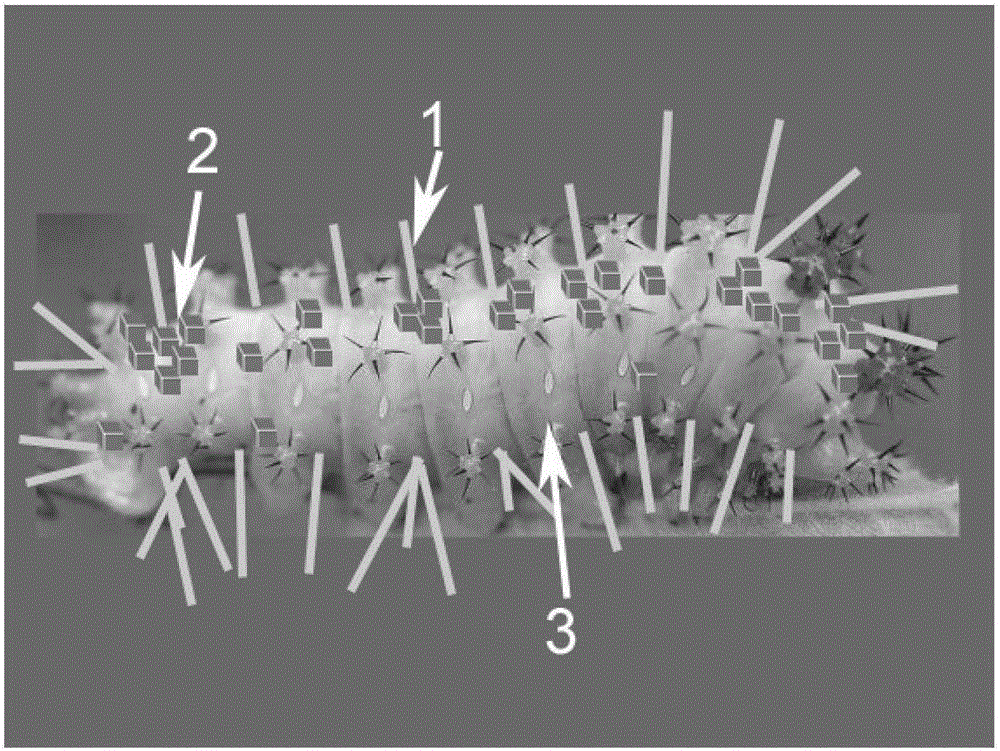

[0026] combined with figure 1 , 2

[0027] A direct sodium borohydride fuel cell anode, using foamed nickel 3 as a current collector, the foamed nickel 3 is covered with corrosion pits, the size of the corrosion pits is on the order of nanometers, and Pd nanorods 1 or Pd nanorods 1 or Pd nanorods are grown in each corrosion pit. The particle 2, the Pd nanorod 1 or the Pd nanoparticle 2 is used as the anode catalyst of the fuel cell.

[0028] The Pd nanorods 1 do not overlap each other; the Pd nanoparticles 2 do not overlap each other.

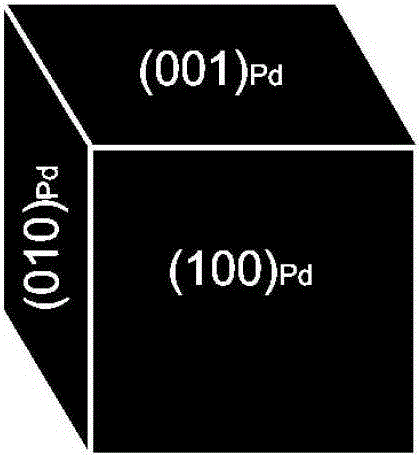

[0029] Pd nanorod 1 has four sides, each of which is {100} Pd Planes.

[0030] The Pd nanorod 1 has a diameter of 3-50 nm, a length of 20-500 nm, and a spatial shape of a cuboid.

[0031] Pd nanoparticle 2 has six surfaces, each of which is {100} Pd Planes.

[0032] The spatial shape of Pd nanoparticles 2 is close to a cube, and the side length is 2~20nm;

[0033] Manufacture the preparation method of described direct sodium borohydride...

Embodiment 2

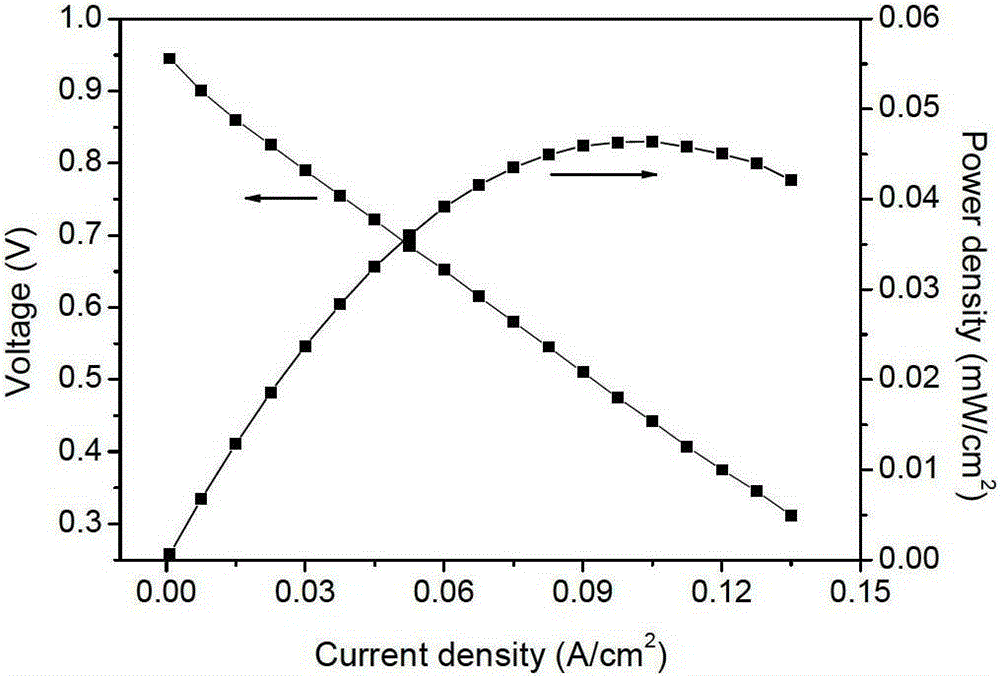

[0044] Dip nickel foam in dilute hydrochloric acid solution and corrode for 1~4h, take it out, clean it and dry it. Afterwards, the corroded nickel foam was immersed in a mixture of polyvinylpyrrolidone, sodium chloropalladate, potassium bromide, ethanol and ascorbic acid at 60 o C kept the reaction for 12h. Take out the nickel foam covered with Pd nanorods on the surface, rinse it with clean water, dry it naturally, and cut it into an area of 2*3cm. The diameter of the Pd nanorods is 3~50nm, the length is 20~500nm, and the spatial shape is a cuboid. Four Both sides are {100} Pd Planes. A direct sodium borohydride fuel cell is assembled with Pt / C as cathode, N117 membrane as electrolyte membrane, nickel foam of the present invention as anode current collector and catalyst. The battery discharge test results after feeding sodium borohydride alkaline fuel and oxygen show that the battery has good electrical output performance, and the maximum output power density exceeds 60...

Embodiment 3

[0046] Dip nickel foam in dilute sulfuric acid solution and corrode for 0.5~6h, take it out, clean it and dry it. Afterwards, the corroded nickel foam was immersed in a mixture of polyvinylpyrrolidone, sodium chloropalladate, potassium bromide, ethanol and sodium borohydride at 10 o C kept the reaction for 0.1h. Take out the nickel foam covered with Pd nanoparticles on the surface, rinse it with clean water, dry it naturally, and cut it into an area of 2*3cm. The spatial shape of the Pd nanoparticles is close to a cube, the side length is 2~20nm, and the six sides are {100} Pd Planes. A direct sodium borohydride fuel cell is assembled with Pt / C as cathode, N117 membrane as electrolyte membrane, nickel foam of the present invention as anode current collector and catalyst. The battery discharge test results after feeding sodium borohydride alkaline fuel and oxygen show that the battery has good electrical output performance, and the maximum output power density exceeds 45mW / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com