Preparation method of 4, 6-dichloropyrimidine

A technology of dichloropyrimidine and dihydroxypyrimidine, which is applied in the field of preparation of pesticide raw materials, can solve problems such as high technical requirements, large amount of three wastes, and high risk of phosgene, and achieve mature and reliable process technology, reduce risks, and be environmentally friendly Effect

Inactive Publication Date: 2013-02-20

LIANYUNGANG GUOSHENG CHEM

View PDF3 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0008] However, in the actual production process, it is found that phosgene is dangerous, has high technical requirements, and the yield and product quality are not very high; phosphorus oxychloride production needs phosphorus oxychloride, and phosphorus oxychloride is a highly toxic chemical, and the production Production accidents are easy to occur during the process, the risk is also high, the amount of three wastes is large, separation is difficult, and energy consumption is high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

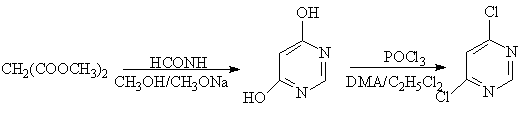

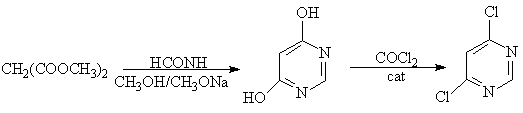

The invention provides a preparation method of 4, 6-dichloropyrimidine. The preparation method comprises the following steps: feeding formamide, absolute ethyl alcohol and sodium ethoxide into a container; stirring and heating; dropping diethyl malonate; reflowing and maintaining the temperature after the dropping; recovering the absolute ethyl alcohol and water-containing ethyl alcohol; dropping hydrochloric aqueous solution until the pH (Potential of Hydrogen) of the reaction liquid is 2 to 6; cooling; centrifuging and drying to obtain 4, 6-dihydroxypyrimidine; feeding the 4, 6-dihydroxypyrimidine, dichloroethane and a chlorination catalyst into the container; stirring and slowly heating until reaching reflowing; dropping thionyl chloride; maintaining the temperature after the dropping; then cooling; recovering the dichloroethane; collecting the dichloroethane and finished product; cooling the finished product in a crystallizing kettle; and centrifuging and drying to obtain the finished product of 4, 6-dichloropyrimidine. The preparation method can reduce the risk, is more reasonable in technology, simple and convenient, low in cost, high in quality, environmentally friendly, and more specifically suitable for industrial production, and can reach over 83% of the total reaction yield based on diethyl malonate; and the quality of the 4, 6-dichloropyrimidine meets international standard.

Description

technical field [0001] The invention relates to a method for preparing pesticide raw materials, in particular to a method for preparing 4,6-dichloropyrimidine. Background technique [0002] 4,6-dichloropyrimidine is the raw material for the synthesis of azoxystrobin. The chemical name of azoxystrobin is (E)2-[2-[6-(2-cyanophenoxy)pyrimidin-4-yloxy]benzene Base]-3-methyl methoxyacrylate, this product is a methoxyacrylate (Strobilurin) fungicide, highly efficient, broad-spectrum, for almost all fungal kingdoms (Ascomycotina, Basidiomycotina, Flagella Mycotina and Deuteromycotina) diseases such as powdery mildew, rust, glume blight, net spot, downy mildew, rice blast, etc. have good activity. It can be used for stem and leaf spray, seed treatment, and soil treatment. It is mainly used for grain, rice, peanut, grape, potato, fruit tree, vegetable, coffee, lawn, etc. [0003] Currently reported synthetic methods, due to consideration of the yield and manufacturing costs, the cy...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07D239/30

Inventor 张鑫周土林汤惠青

Owner LIANYUNGANG GUOSHENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com