Bismuth ferrite-graphene nanometer composite material for the filed of photocatalysis and preparation method thereof

A nanocomposite material and graphene technology, applied in the field of bismuth ferrite-graphene composite material and its preparation, can solve the problems of low photocatalytic efficiency, high recombination rate of photogenerated electrons and holes, low quantum efficiency, etc. The effect of large surface area, excellent photocatalytic performance and high utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

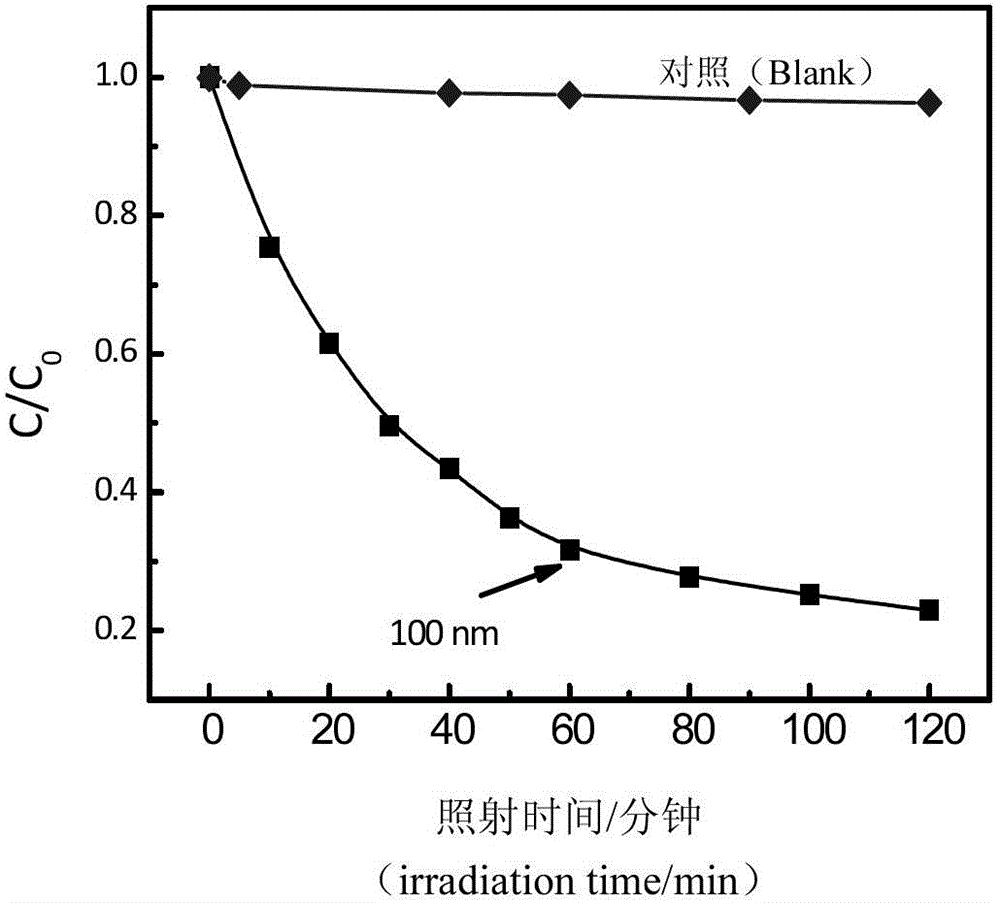

[0028] Example 1, Preparation of bismuth ferrite-graphene nanocomposite material and evaluation of photocatalytic effect

[0029] According to the molar ratio of bismuth nitrate (0.0033mol) and ferric nitrate (0.003mol) 1.1:1, add 100ml2mol / L of HNO 3 , stirred for about half an hour until it was completely dissolved, and the solution was colorless and transparent, and then 12mol / L KOH solution was added dropwise until the brick red precipitate no longer increased. Then add 0.05g KNO 3 Stir until completely dissolved. Add 0.02 g of graphene, and ultrasonically disperse for 2 hours to obtain a uniformly mixed precursor solution. The above mixed solution was transferred to a reaction kettle, and heated to 200°C at a heating rate of 5°C / min for 12 hours to obtain black BiFeO 3 - Graphene composite material 1.03g. Measured by thermogravimetric method, BiFeO in the obtained composite material 3 The mass is 0.98g.

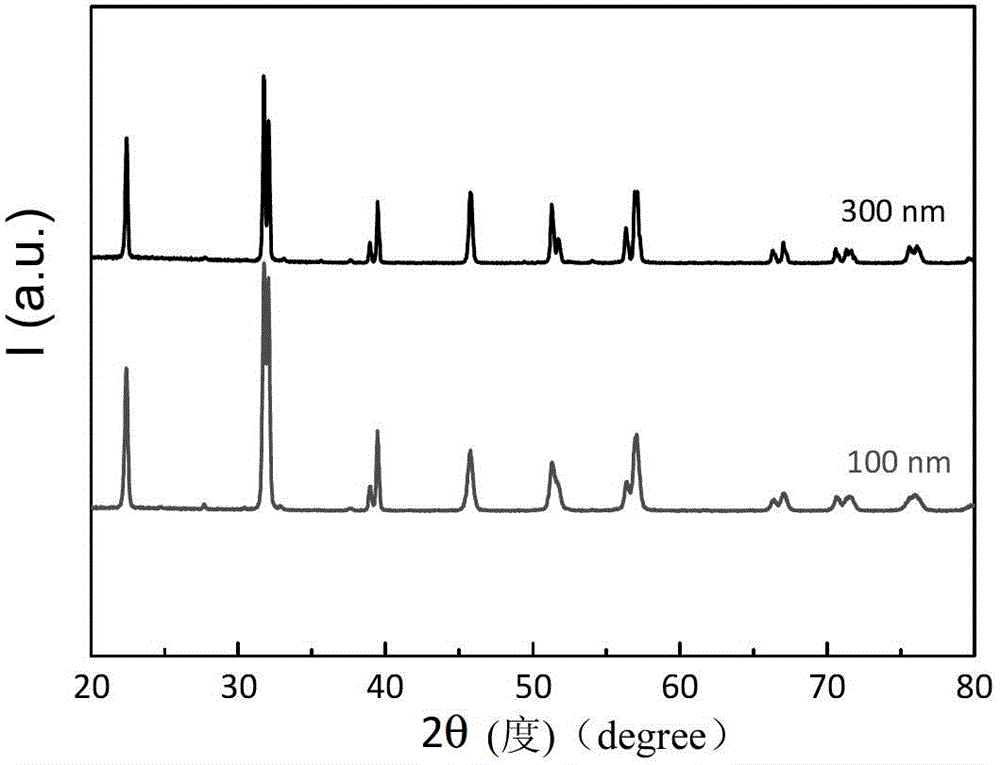

[0030] figure 1 It is the XRD pattern of the product, and it...

Embodiment 2

[0032] Example 2, Preparation of bismuth ferrite-graphene nanocomposite material and evaluation of photocatalytic effect

[0033] According to the molar ratio of bismuth nitrate (0.0033mol) and ferric nitrate (0.003mol) 1.1:1, add 100ml2mol / L of HNO 3 , stirred for about half an hour until completely dissolved, the solution was colorless and transparent, and then 12mol / L KOH solution was dropped to form a brick red precipitate. Then add 0.05g KNO 3 Stir until completely dissolved. Add 0.03 g of graphene, and ultrasonically disperse for 2 hours to obtain a uniformly mixed precursor solution. The above mixed solution was transferred to the reaction kettle, and heated to 200°C at a heating rate of 5°C / min for 24 hours to obtain black BiFeO 3 -graphene composite 1.04g. Measured by thermogravimetric method, BiFeO in the obtained composite material 3 The mass is 0.95g.

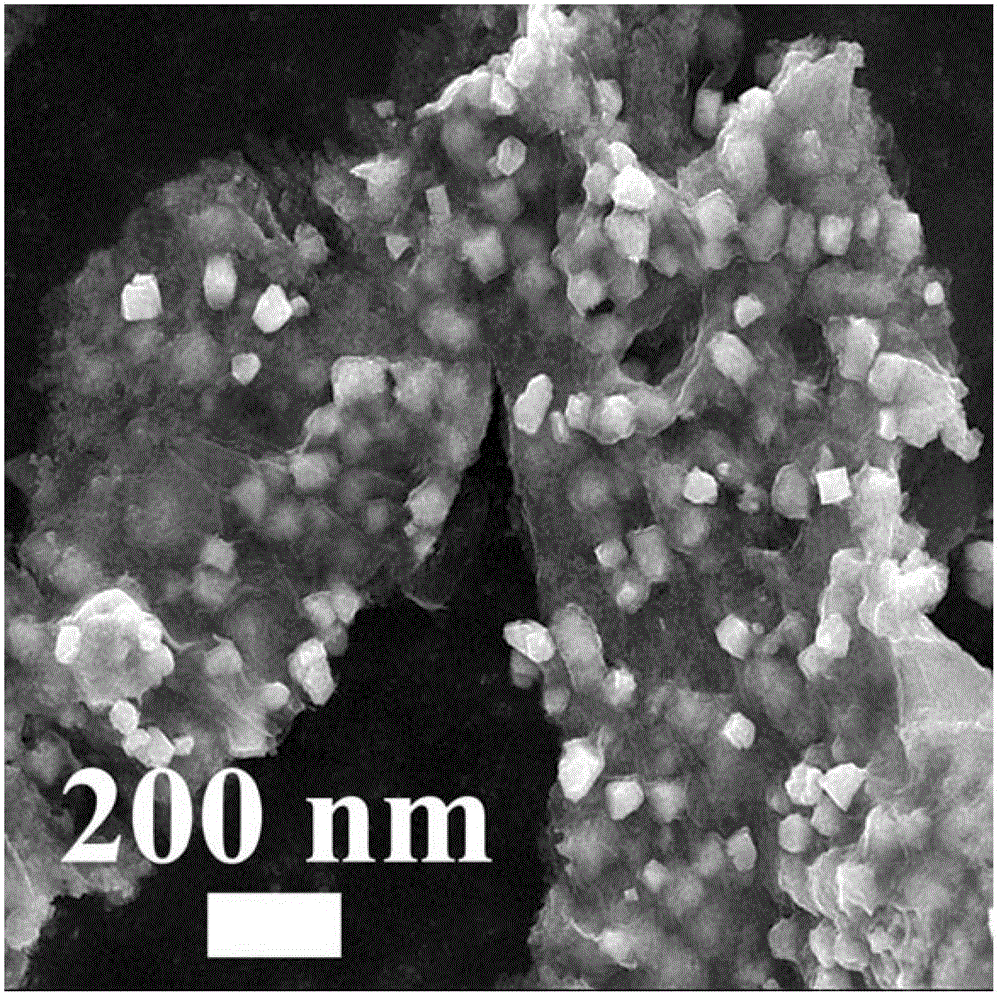

[0034] Figure 4 BiFeO prepared for this example 3 -SEM image of graphene composite material, BiFeO with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com