Nickel-based brazing material and method for preparing alloy coating by nickel-based brazing material

A nickel-based solder and alloy coating technology, applied in the field of alloys, can solve problems such as difficult to form thicker coatings on the surface of workpieces, single corrosion-resistant environment, etc., achieve excellent corrosion resistance to various corrosive media, and coating thickness can be adjusted The effect of control and excellent braze coating process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

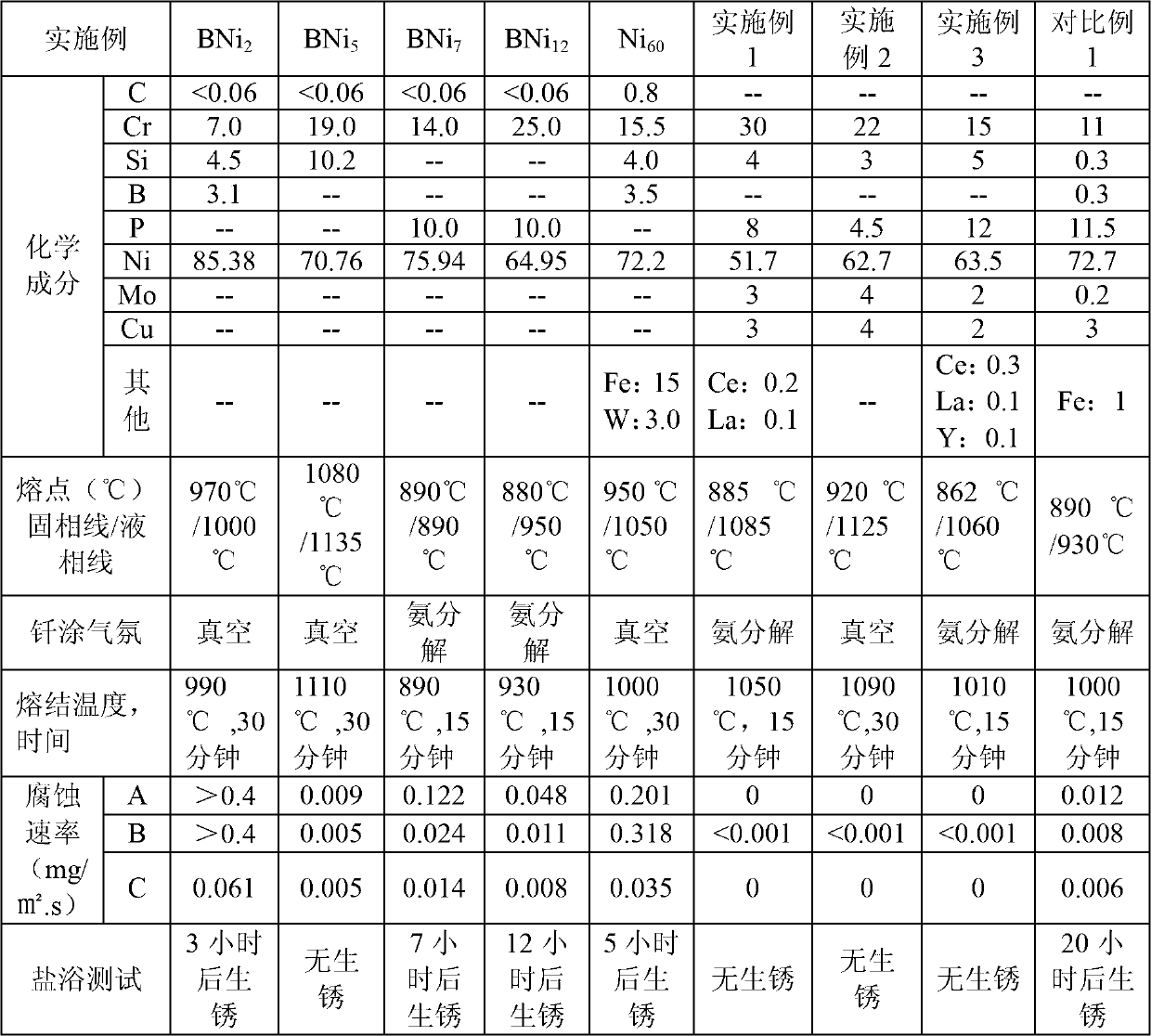

[0046] The binders in Examples 1-3 were purchased from Hunan Xinguanghuan Technology Development Co., Ltd., model: HJbinder-1208, and other materials and instruments are commercially available.

[0047] Will BNi 2 、BNi 5 、BNi 7 、BNi 12 、Ni 60 Mix the nickel-based brazing filler metal and the nickel-based brazing filler metal and binder of Examples 1 to 3 at a weight ratio of 1:1, stir evenly to obtain an alloy paste, and soak the ordinary No. 45 carbon steel workpiece in the alloy paste , after drying, place them in a vacuum brazing furnace or an ammonia decomposition atmosphere protection brazing furnace, carry out brazing coating and sintering treatment, and take out the furnace at 80°C to obtain a workpiece with an alloy coating. The corrosion resistance of each nickel-based alloy coating was tested respectively.

[0048] The symbol A indicates that the nickel-based solder is mixed with H at a mass concentration of 5%. 2 SO 4 Soak at 60°C for 24 hours

[0049] Symbo...

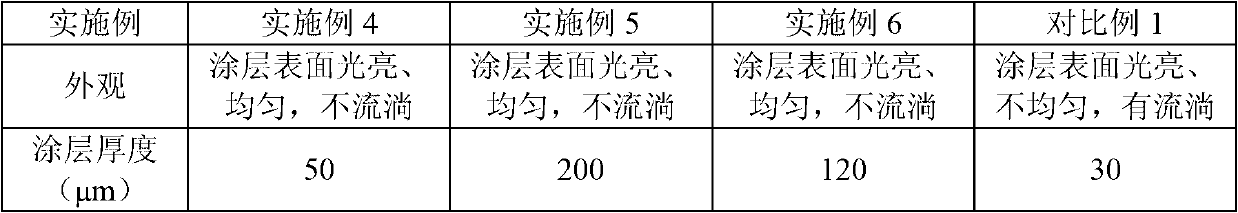

Embodiment 4

[0055] 1. Melting the nickel-based brazing filler metal of 2Kg embodiment 1 into an alloy liquid in a nitrogen protection environment, then carrying out the atomization cooling step with high-speed nitrogen gas to obtain a particle size of -150 object nickel-based brazing filler metal powder mixed with 8Kg of binder, Stir evenly to obtain alloy paste.

[0056] 2. Select No. 45 carbon steel pipes with an inner diameter of 30mm, a wall thickness of 2mm, and a length of 300mm for rust and oil removal, and then dry them to obtain clean carbon steel pipes.

[0057] 3. Soak the clean carbon steel pipe in the alloy paste to obtain the carbon steel pipe coated with the paste.

[0058] 4. Dry the carbon steel pipe coated with the alloy paste in a drying cabinet at 50° C. to obtain a dried carbon steel pipe.

[0059] 5. Put the dry carbon steel pipe in a brazing furnace protected by an ammonia decomposition atmosphere, adjust the sintering temperature to 1050°C for 15 minutes, and take...

Embodiment 5

[0061] 1. Melt 8Kg of the nickel-based solder of Example 2 into an alloy liquid in a vacuum, then use high-speed nitrogen to carry out the atomization cooling step to obtain a particle size of -150 mesh nickel-based solder powder mixed with 2Kg of binder, and stir evenly Obtain alloy paste.

[0062] 2. Select No. 45 carbon steel pipes with an inner diameter of 30mm, a wall thickness of 2mm, and a length of 300mm for rust and oil removal, and then dry to obtain a clean carbon steel pipe.

[0063] 3. Soak the clean carbon steel pipe in the alloy paste to obtain the carbon steel pipe coated with the paste.

[0064] 4. Dry the carbon steel pipe coated with the alloy paste in a drying cabinet at 70° C. to obtain a dried carbon steel pipe.

[0065] 5. Put the dry carbon steel pipe in the vacuum brazing furnace and start heating after vacuuming. The sintering temperature is 1090°C and the vacuum degree is 10 -1 Sintering at Pa for 30 minutes, and taking out the alloy-coated carbon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com