Water injected pitting-corrosion composite inhibitor and application thereof

A compound inhibitor and inhibitor technology, which is applied in wellbore/well components, earthwork drilling and production, etc., can solve the problem of unsatisfactory pitting corrosion inhibition effect, and achieve the effect of corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

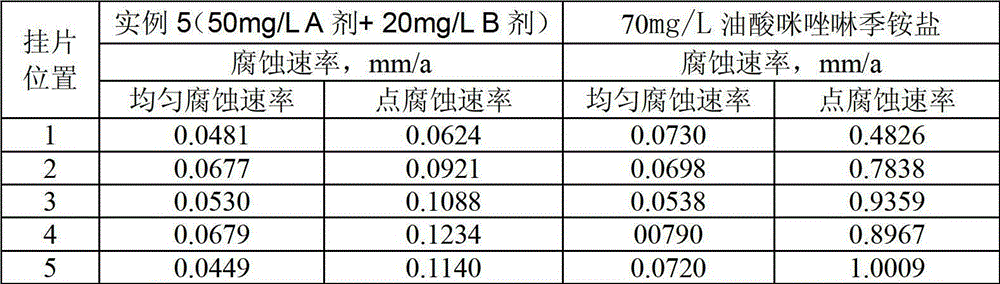

Examples

Embodiment 1

[0020] Agent A consists of 30% lauric acid imidazoline quaternary ammonium salt, 10% naphthenic acid amide, 1% fatty alcohol polyoxyethylene ether, 8% dodecyl dimethyl benzyl quaternary ammonium salt, 4% thiourea, 8% % potassium benzoate, 15% isopropanol, 24% ethanol; agent B is dodecyl trimethyl quaternary ammonium salt.

Embodiment 2

[0022] Agent A consists of 25% salicylic acid imidazoline quaternary ammonium salt, 5% oleic acid amide, 5% alkylphenol polyoxyethylene ether, 10% fatty acid polyoxyethylene ether, 1% hexadecyldimethylbenzyl quaternary Ammonium salt, 3% thiourea, 1% benzoic acid, 20% methanol, 30% ethanol; composition; agent B is dodecyl dimethyl diquaternary ammonium salt.

Embodiment 3

[0024] Agent A consists of 20% imidazoline quaternary ammonium benzoate, 15% lauric acid amide, 10% fatty amine polyoxyethylene ether, 1% dodecyl trimethyl quaternary ammonium salt, 3% thiourea, 2% benzoic acid , 20% methanol, 10% isopropanol, 19% methanol; agent B is dodecyl tributyl quaternary phosphine salt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com