Preparation method of anti-bacterial ultraviolet-resistant textile

A textile and anti-ultraviolet technology, which is applied in the direction of textiles and papermaking, fiber treatment, plant fiber, etc., can solve the problems of poor functional durability, material performance decline, and large specific surface energy, and achieve good air permeability and washing fastness. The effect of low condition requirements and strong functional durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

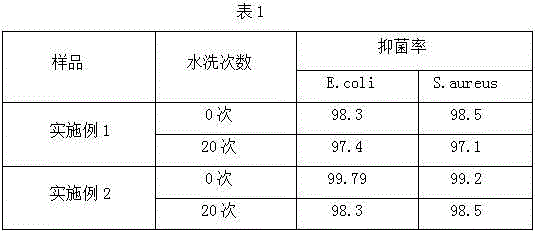

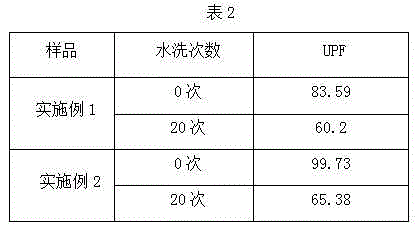

Embodiment 1

[0020] This example provides a method for preparing in-situ nano zinc oxide antibacterial and anti-ultraviolet textiles.

[0021] Preparation of the finishing solution: prepare 100ml mass percent of 0.4% amino-terminated hyperbranched compound aqueous solution (synthesized by diethylenetriamine and acrylic acid) and 0.01mol / l Zn(NO 3 ) 2 of the mixture.

[0022] Cotton fabrics were put into the mixed solution with a bath ratio of 1:50, and oscillated and reacted in a constant temperature water bath at 60°C for 20 minutes, then heated up to 100°C at a rate of 2°C / min, oscillated at a constant temperature for 2 hours, and the fabric was taken out, washed and dried to obtain nano ZnO antibacterial and antibacterial agents. UV cotton fabric.

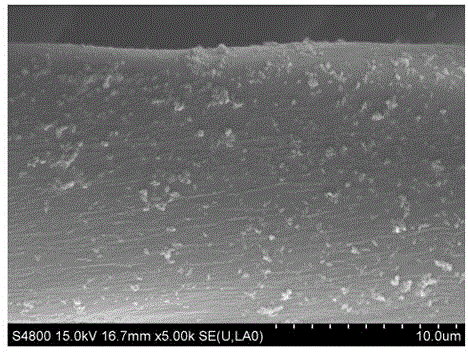

[0023] See attached figure 1 , which is the SEM image of in-situ generated nano-ZnO on the surface of cotton fabric fibers provided in this example. It can be seen from the figure that there are a large number of tiny nano-ZnO particles ...

Embodiment 2

[0025] Cotton fabric modified amino-terminated hyperbranched compound treatment: the cotton fabric was dipped in an aqueous solution of 0.6% modified amino-terminated hyperbranched compound for 20 minutes. The preparation method of the modified amino-terminated hyperbranched compound is: get 1g of dodecanoic acid and add it to 20g of the amino-terminated hyperbranched compound synthesized by diethylenetriamine and methyl acrylate and 10ml of methanol solution, move to the rotary evaporator after dissolving, and heat up The polycondensation reaction is carried out at 150° C. to obtain a modified amino-terminated hyperbranched compound. The modified amino-terminated hyperbranch has a larger molecular weight and a long-chain structure, and has stronger adsorption to fibers.

[0026] The above-mentioned cotton fabric loaded with modified amino-terminated hyperbranched compound, in the ZnCl of 0.05mol / L 2 Immerse in the solution, steam for 10 minutes after taking it out, wash with...

Embodiment 3

[0032] Place 52m1 polyamino compound divinyltriamine in a 250m1 three-necked flask, cool in an ice-water bath, and place in N 2 Under protection, use a constant pressure funnel to slowly add a mixed solution of 43m1 methyl acrylate and 100m1 methanol dropwise, and react at room temperature for 4 hours after the dropwise addition to obtain light yellow transparent AB 2 and AB 3 type monomer. Then it was transferred to a rotary evaporator eggplant-shaped flask, methanol was removed under reduced pressure, the temperature was raised to 150°C to continue the reduced-pressure reaction for 4 hours, and the reaction was stopped to obtain a viscous light yellow amino-terminated hyperbranched compound. Dissolve 4 g of the obtained amino-terminated hyperbranched polymer in 50 ml of chloroform, add 7 g of poly(ethylene glycol) methyl ether acrylate, stir at room temperature for 12 h, then heat to 50° C. and stir for 12 h, and vacuum-dry to obtain the modified Amino-terminated hyperbran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com