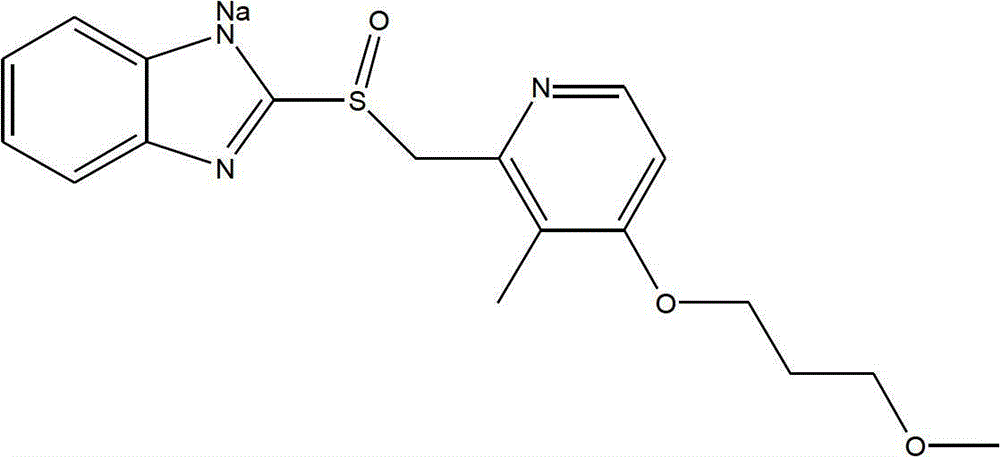

Sodium rabeprazole composition for injection

A technology of rabeprazole sodium and its composition, which is applied in the field of pharmaceutical preparations, can solve the problems of low production efficiency, shortened freeze-drying time, and long freeze-drying time, and achieve low production cost, shortened freeze-drying time, and low water content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

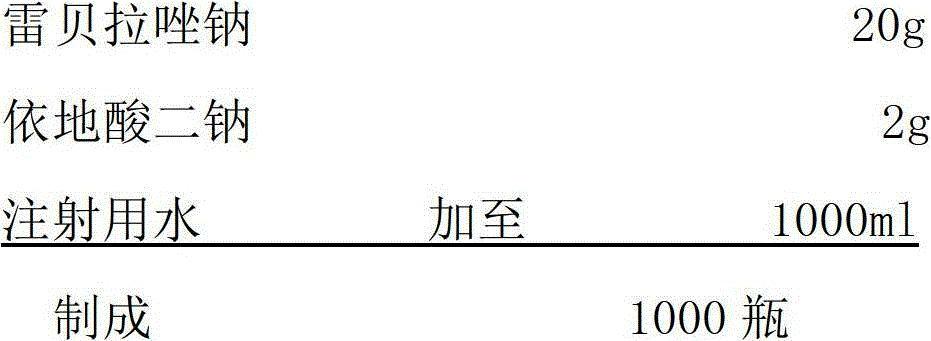

Embodiment 1

[0088] prescription:

[0089]

[0090] Weigh rabeprazole sodium and edetate disodium into the preparation tank, add water for injection, stir to dissolve and mix evenly, adjust the pH value of the solution to 10.5~12.5 with sodium hydroxide; use a 0.22um filter for the prepared medicinal solution Sterilize and filter to a sterile room, dispense into vials, and half stoppered with rubber. The product was first pre-frozen to -45°C, kept warm for 2 hours, started vacuuming, raised the temperature to 0°C, kept for 4 hours, then raised to 40°C, kept for 5 hours, and kept at 30°C for 3 hours to obtain the composition needle.

Embodiment 2

[0092] prescription:

[0093]

[0094] Weigh rabeprazole sodium and edetate disodium into the preparation tank, add water for injection, stir to dissolve and mix evenly, adjust the pH value of the solution to 10.5~12.5 with sodium hydroxide; use a 0.22um filter for the prepared medicinal solution Sterilize and filter to a sterile room, dispense into vials, and half stoppered with rubber. The product was first pre-frozen to -45°C, kept warm for 2 hours, started vacuuming, raised the temperature to 0°C, kept for 4 hours, then raised to 40°C, kept for 5 hours, and kept at 30°C for 3 hours to obtain the composition needle.

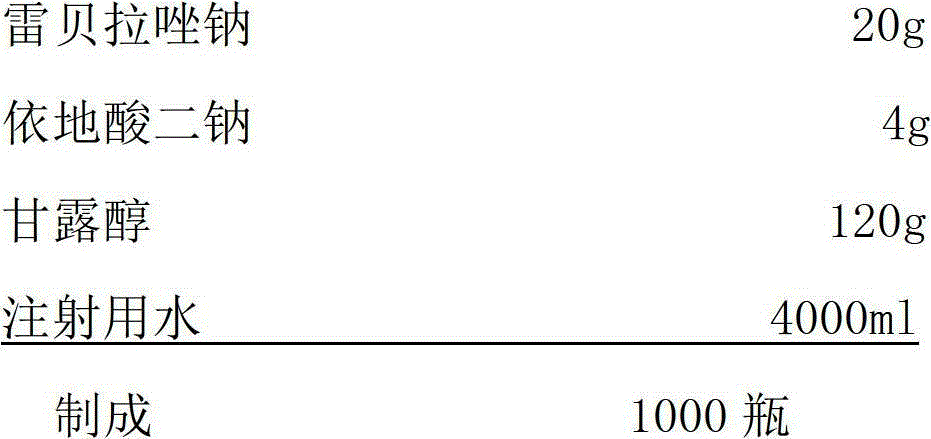

Embodiment 3

[0096] prescription:

[0097]

[0098] Weigh rabeprazole sodium and edetate disodium into the preparation tank, add water for injection, stir to dissolve and mix evenly, adjust the pH value of the solution to 10.5~12.5 with sodium hydroxide; use a 0.22um filter for the prepared medicinal solution Sterilize and filter to a sterile room, dispense into vials, and half stoppered with rubber. The product was first pre-frozen to -45°C, kept warm for 2 hours, started vacuuming, raised the temperature to 0°C, kept for 4 hours, then raised to 40°C, kept for 5 hours, and kept at 30°C for 3 hours to obtain the composition needle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com