Laser transmission welding method for thermoplastic plastics

A technology of laser transmission welding and thermoplastics, which is applied in the field of laser welding, can solve the problems of non-conductivity, thermal conductivity change, difficulty in optimizing the range of laser welding process parameters, and two workpieces can no longer be separated, etc., to achieve enhanced strength and good conductivity / insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

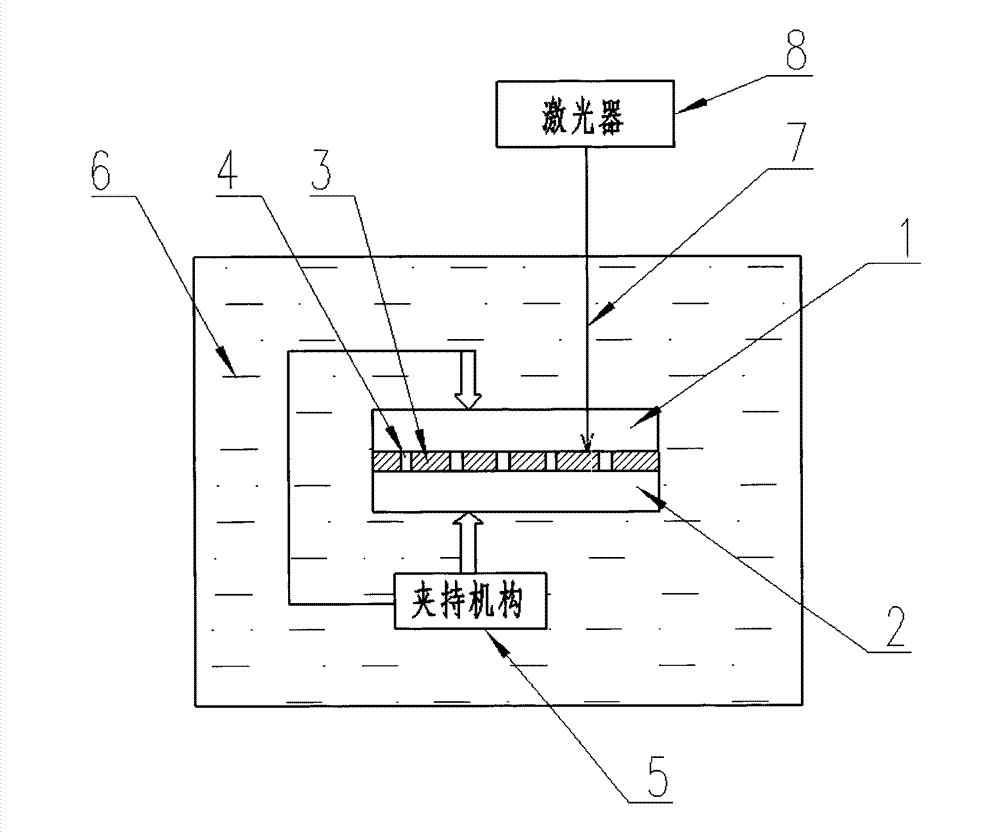

[0035] Such as figure 1 As shown, the invention provides a kind of laser transmission welding method of thermoplastics, comprising the following steps:

[0036] (1) A welding frame 3 is placed between two upper hard plastics 1 and lower hard plastics 2 to be welded; the upper hard plastic 1 is a thermoplastic that can transmit laser beams, and the welding frame 3 It is a hard material that can absorb laser beams. In the present embodiment, the upper hard plastic 1 and the lower hard plastic 2 adopt polyethylene terephthalate (PET) with a thickness of 10mm, and the lower hard plastic 2 adopts polyethylene terephthalate (PET). Carbonate (PC) with a thickness of 10mm; the welding skeleton 3 adopts a thin copper sheet with a thickness of 1mm; the melting point of the welding skeleton 3 is higher than that of the upper hard plastic 1 and the lower hard plastic 2, and the welding skeleton 3 There are several through holes 4; the position, size and shape of the through holes 4 can b...

Embodiment 2

[0045] The invention provides a thermoplastic laser transmission welding method, comprising the following steps:

[0046] (1) A welding frame 3 is placed between the two upper hard plastics 1 and the lower hard plastic 2 to be welded; the upper hard plastic 1 is a thermoplastic that can transmit laser beams; the welding frame 3 It is a hard material that can absorb laser beams, the melting point of the welding skeleton 3 is higher than the melting point of the upper hard plastic 1 and the lower hard plastic 2, and several through holes 4 are arranged on the welding skeleton 3; in this embodiment The upper hard plastic 1 is made of polycarbonate (PC) with a thickness of 50mm; the lower hard plastic 2 is made of polybutylene terephthalate (PBT) with a thickness of 100mm, and the welding skeleton 3 is made of aluminum oxide with a thickness of 0.5mm Ceramics;

[0047] (2) The upper hard plastic 1 and the lower hard plastic 2 are clamped by the clamping mechanism 5, that is, pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com