Method for separating ranolazine by adopting simulated moving bed

A technology for simulating moving bed and ranolazine is applied in the field of simulated moving bed chromatographic separation of ranolazine, which can solve the problems such as the separation and preparation of ranolazine racemates that have not yet been seen, and achieve continuous automation of production, stable product quality and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

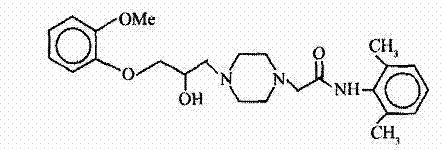

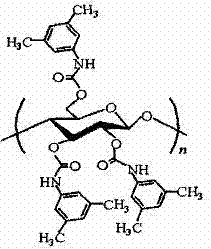

[0030] 1. Preparation of cellulose-tris(3,5-dimethylphenylcarbamate) filler

[0031] Prepare according to the method of literature (Okamoto Y, Kawashima M, Hatada K J . Chromatogr.1986,363:173~186). Cellulose and phenyl isohydrogen were reacted in pyrrole solution at 100°C for 24 hours, and the methanol-incompatible substance obtained from the reaction was cellulose-tris(3,5-dimethylphenylcarbamate). Cellulose-tris(3,5-dimethylphenylcarbamate) was dissolved in tetrahydrofuran, and aminopropyl silica gel was added to the solution, and electromagnetically stirred until the tetrahydrofuran was volatilized, and repeated 3 times to obtain cellulose- Tris(3,5-dimethylphenylcarbamate) coated chiral stationary phase. Wherein the weight ratio of cellulose-three (3,5-dimethylphenylcarbamate) to aminopropyl silica gel is 1:5;

[0032] 2. Selection of mobile phase flow rate

[0033] The flow rate of the mobile phase affects the separation of ranolazine enantiomers and also affects the ...

example 1

[0055] A operating conditions

[0056] Mobile Phase: Methanol

[0057] Injection concentration: 5g / ml

[0058] Injection liquid flow rate: 1.5 ml / min

[0059] Eluent flow rate: 3.0 ml / min

[0060] Extraction flow rate: 2.5 ml / min

[0061] Raffinate flow rate: 2.0 ml / min

[0062] Switching time: 6.8min

[0063] System temperature: 30°C

[0064] B finished product analysis

[0065] Analyzing the composition of the extract and raffinate with an analytical column, the purity of the extract is 99.5%, and the purity of the raffinate is 99.3%. Each kilogram of stationary phase can produce 33.5kg of R-ranolazine and S-ranolazine per day. The phase consumption was 0.128L / kg, and the recovery rate was 99.2%.

[0066]

example 2

[0068] A operating conditions

[0069] Mobile Phase: Methanol

[0070] Injection concentration: 5g / ml

[0071] Injection liquid flow rate: 1.0 ml / min

[0072] Eluent flow rate: 2.5 ml / min

[0073]Extraction flow rate: 1.7 ml / min

[0074] Raffinate flow rate: 1.8 ml / min

[0075] Switching time: 7.5min

[0076] System temperature: 30°C

[0077] B finished product analysis

[0078] Analyzing the composition of the extract and raffinate with an analytical column, the purity of the extract is 99.4%, and the purity of the raffinate is 99.5%. Each kilogram of stationary phase can produce 22kg of R-ranolazine and S-ranolazine per day, and the mobile phase The consumption is 0.163L / kg, and the recovery rate is 97.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com