Application method of cigarette smoke heavy metal ion adsorbent obtained through chemical cross-linking

A technology of cigarette smoke and chemical cross-linking, which is applied in the direction of chemical instruments and methods, applications, and other chemical processes, can solve the problems of large amount of polyethyleneimine, etc., to improve selectivity, maintain mechanical strength, increase ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

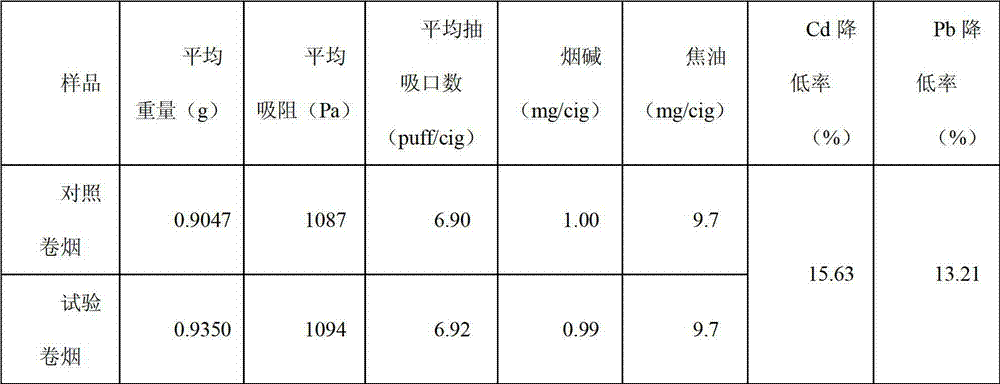

Embodiment 1

[0024] Pass the silica gel dried to constant weight through a 40-60 mesh sieve, then place it in a 120°C oven and heat it for 5-8 hours at high temperature to activate it to obtain the activated silica gel.

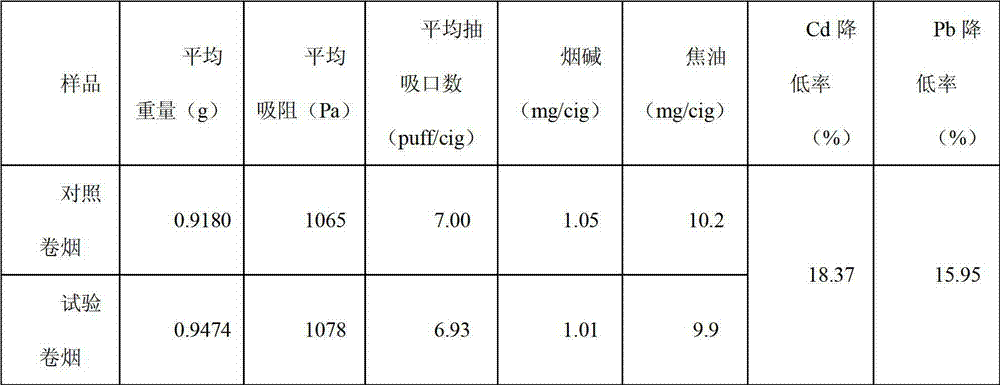

Embodiment 2

[0026] Take out 5g of activated silica gel after drying, put it into a dry three-necked flask, use about 30mL of xylene solvent, heat and stir to 80°C, then add about 10mL of propylene oxide, control the reaction temperature at about 90°C, and prepare epoxidized of silicone. After reacting for 6 hours, filter the reaction product with suction, dry the epoxidized silica gel at 100°C for 30 minutes, put it into a Soxhlet extraction tube and extract it with toluene for 24 hours, remove excess propylene oxide in the product, and put it in a vacuum drying oven Dry at 80°C for 20 hours to obtain epoxidized silica gel.

[0027] Put the dried epoxidized silica gel into a three-necked flask, add 50% polyethyleneimine aqueous solution with a molecular weight of 70,000, so that the mass ratio of polyethyleneimine to silica gel in the adsorbent is 2.5:100, at 90°C The reaction was stirred for 8h. After the reaction, rinse with a large amount of water, filter with suction, and put it int...

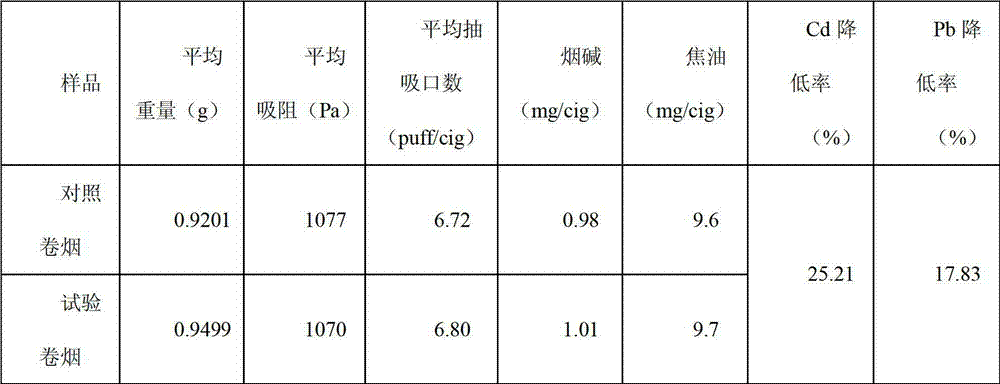

Embodiment 3

[0031] Take out 5g of activated silica gel after drying, put it into a dry three-necked flask, use xylene as solvent about 30mL, heat and stir to 80°C, then add about 10mL of propylene oxide, and control the reaction temperature at about 90°C to prepare epoxy melted silica gel. After reacting for 6 hours, filter the reaction product with suction, dry the epoxidized silica gel at 100°C for 30 minutes, put it into a Soxhlet extraction tube and extract it with toluene for 24 hours, remove excess propylene oxide in the product, and put it in a vacuum drying oven Dry at 80°C for 20 hours to obtain epoxidized silica gel.

[0032] Put the dry epoxidized silica gel into a three-necked flask, add 50% polyethyleneimine aqueous solution with a molecular weight of 70,000, so that the mass ratio of polyethyleneimine to silica gel in the adsorbent is 5:100, at 90°C The reaction was stirred for 8h. After the reaction, rinse with a large amount of water, filter with suction, and put it into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com