Method for photocatalytic degradation of pesticide residues

A technology for degrading pesticides and pesticide residues, applied in the field of degradation and removal of pesticide residues, can solve the problems of optical pollution, difficulty in realization, and limited range of pesticide residues, and achieve the effects of low cost, high absorption strength, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

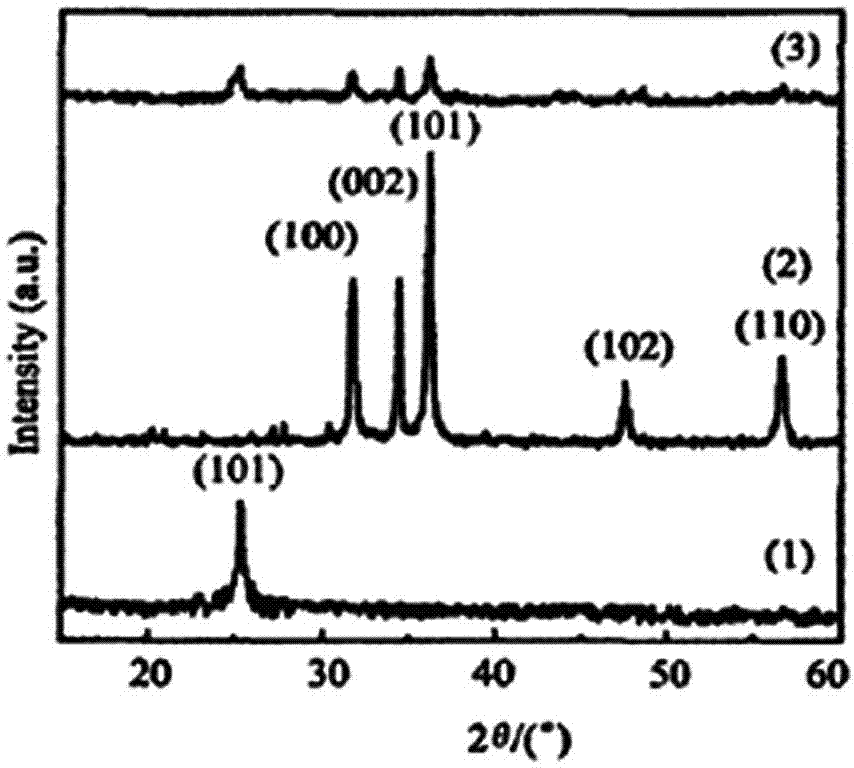

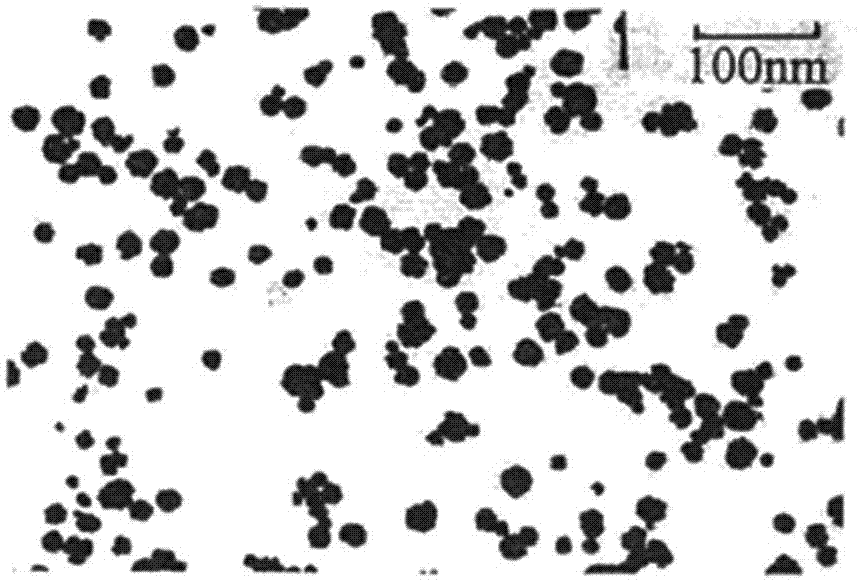

[0023] Dissolve 0.008mol of urea in 40ml of absolute ethanol, mix 0.004mol of butyl titanate and 0.5ml of glacial acetic acid in a 100ml small beaker, then add the ethanol solution of urea dropwise to the butyl titanate under the condition of magnetic stirring Cool and glacial acetic acid in a beaker, after dripping, then magnetically stir for 5min, then transfer the transparent mixed solution to a 50ml polytetrafluoroethylene-lined reaction kettle, put it in a constant temperature box, and keep it at a constant temperature of 150°C After keeping for 18 hours, take it out and cool it down to room temperature naturally. The white precipitate was washed out by centrifugation with distilled water and absolute ethanol, and dried in a drying oven for use.

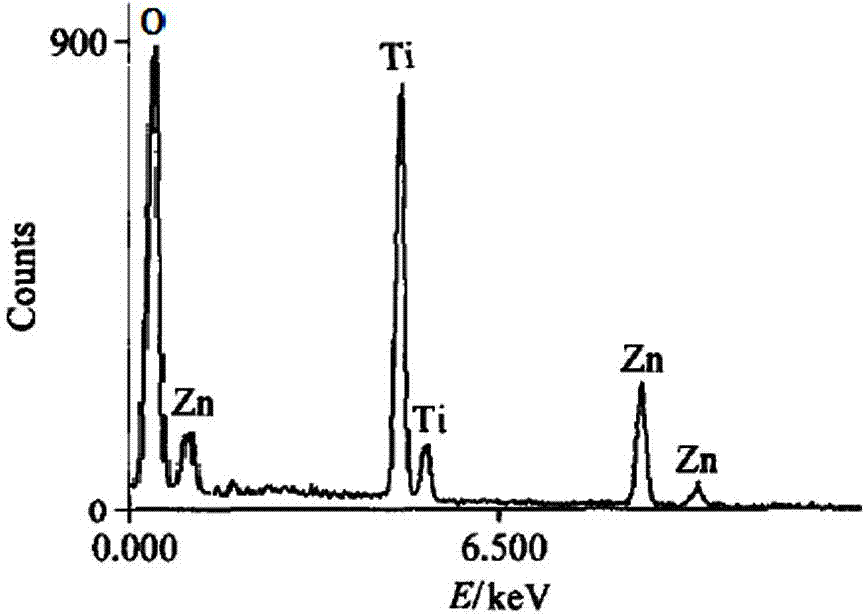

[0024] Take 1g of synthesized TiO 2 Add the powder and zinc acetate into 120ml of distilled water (Zn / Ti molar ratio is 1:1), place it in an ultrasonic instrument for 20 minutes, then slowly add 0.35M sodium hydroxide solution ...

Embodiment 2

[0026] Dissolve 0.016mol of urea in 80ml of absolute ethanol, mix 0.008mol of butyl titanate and 1.0ml of glacial acetic acid in a 250ml small beaker, and then add the ethanol solution of urea dropwise to the butyl titanate under the condition of magnetic stirring Cool and glacial acetic acid beaker, after dripping, then magnetically stir for 10min, then transfer the transparent mixture to a 100ml polytetrafluoroethylene-lined reaction kettle, put it in a constant temperature box, and keep it at a constant temperature of 150°C After keeping for 24 hours, take it out and cool it down to room temperature naturally. The white precipitate was washed out by centrifugation with distilled water and absolute ethanol, and dried in a drying oven for use.

[0027] Take 3g of synthesized TiO 2 Add the powder and zinc acetate into 120ml of distilled water (Zn / Ti molar ratio is 1:1), place it in an ultrasonic instrument for 20 minutes, then slowly add 0.35M sodium hydroxide solution under ...

Embodiment 3

[0029]Dissolve 0.008mol of urea in 40ml of absolute ethanol, mix 0.004mol of butyl titanate and 0.5ml of glacial acetic acid in a 100ml small beaker, then add the ethanol solution of urea dropwise to the butyl titanate under the condition of magnetic stirring Cool and glacial acetic acid in a beaker, after dripping, then magnetically stir for 5min, then transfer the transparent mixed solution to a 50ml polytetrafluoroethylene-lined reaction kettle, put it in a constant temperature box, and keep it at a constant temperature of 150°C After keeping for 18 hours, take it out and cool it down to room temperature naturally. The white precipitate was washed out by centrifugation with distilled water and absolute ethanol, and dried in a drying oven for use.

[0030] Take 8g of synthesized TiO 2 Add the powder and zinc acetate into 120ml of distilled water (Zn / Ti molar ratio is 1:1), place it in an ultrasonic instrument for 30 minutes, then slowly add 0.35M sodium hydroxide solution u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com