Catalyst for preparing alcohol from acetate through hydrogenation as well as preparation method and application thereof

A technology for hydrogenating acetate and producing ethanol, which is used in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, preparation of hydroxyl compounds, etc., and achieves good industrial application prospects, good selectivity, and high activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

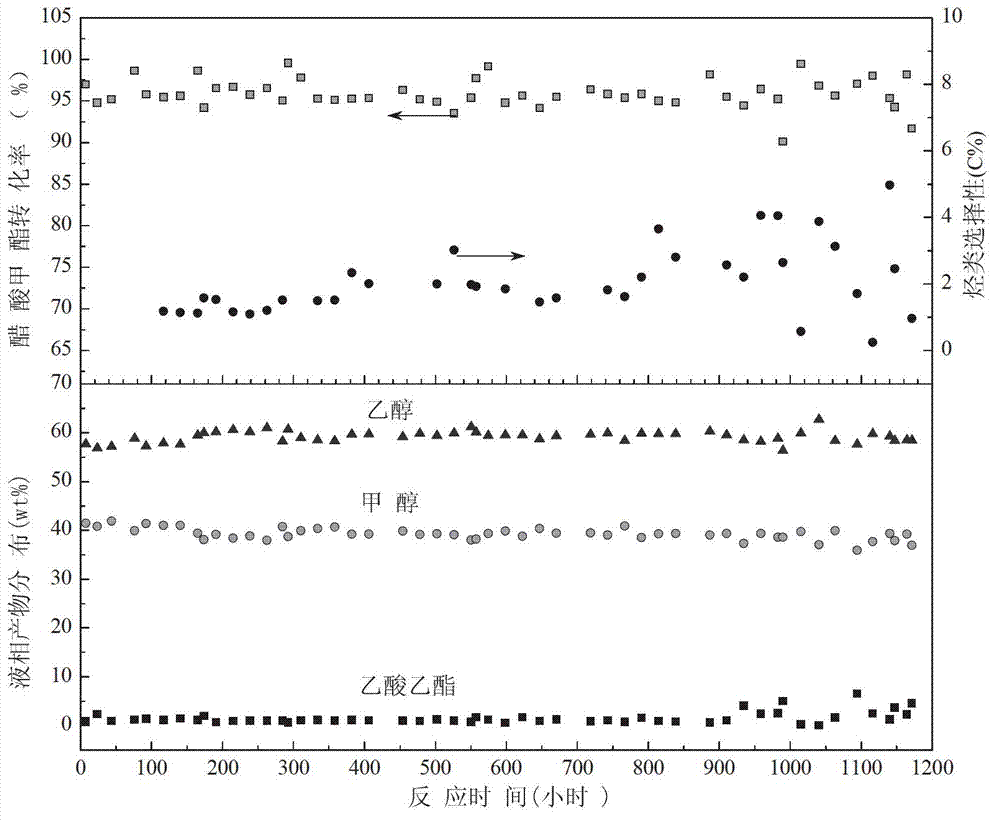

Image

Examples

Embodiment 1

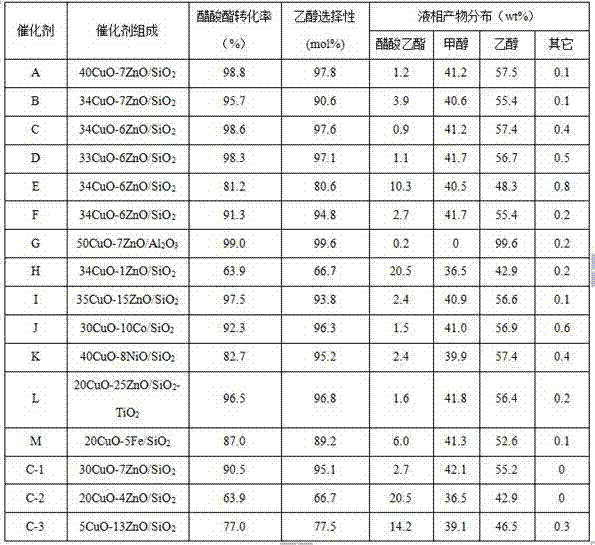

[0023] The composition of catalyst A is: 40CuO-7ZnO / SiO 2

[0024] The preparation steps are as follows: weigh 26.1g Cu(NO 3 ) 2 .3H 2 O, 5.2g Zn(NO 3 ) 2 .6H 2 O, 38.1g TEOS and 36.3g ethanol, 40.1g water in a 500ml beaker, stirred at room temperature for 6h, gelled in air for 24h, slowly heated to 80~120 o C evaporates the solvent, then slowly raises the temperature to 500 o C is calcined for 1 hour to obtain catalyst A.

[0025] The hydrogenation reaction of methyl acetate was carried out in a fixed-bed stainless steel reactor (id=10mm), and the catalyst dosage was 5.0ml. Catalyst before reaction at 310 o C uses 5NL / h of pure H 2 Reduction 48h. Then reduce the reactor to 250 o C, boost the pressure to 8.0Mpa, then inject the acetate into the reactor with a micro metering pump, adjust LHSV=2.0 h -1 , while adjusting H 2 flow such that H 2 / Ester = 50(mol). After reacting for about 80 hours, take samples for analysis, and at the same time analyze the compositi...

Embodiment 2

[0029] The composition of catalyst B is: 34CuO-7ZnO / SiO 2

[0030] Its preparation steps are as follows: weigh 24.1g Cu(NO 3 ) 2 .3H 2 O, 5.0g Zn(NO 3 ) 2 .6H 2 O, 49.5 g TEOS, 44.6 g ethanol, and 47.5 g water were mixed in a 500ml beaker, stirred at room temperature for 2 hours, poured into a plastic bottle and sealed, left to stand at room temperature for about 4 days to form a gel, cut into thin slices and used pH=11 soaked in ammonia water, and then at 75 o Evaporate to dryness on a C water bath, then slowly raise the temperature to 100 o C to dry for 24h, take it out and wash with water until the filtrate is colorless, then slowly rise to 120 o C dry for 12h, then slowly rise to 300 oC is calcined for 1 hour to obtain catalyst B.

[0031] Catalyst evaluation is the same as embodiment 1, and reduction temperature is 400 o C, reduction time 2h, reduction atmosphere 10%H 2 -N 2 ; The reaction condition is 230 o C, 2.0MPa, LHSV=0.5h -1 , H 2 / ester=10 (mol), ...

Embodiment 3

[0033] The composition of catalyst C is: 34CuO-6ZnO / SiO 2

[0034] The preparation steps are basically the same as catalyst B, except that 3.6g of pore-forming agent PEG400 is added before the sealing gel step to obtain catalyst C. The details are as follows: Weigh 24.1 g Cu(NO 3 ) 2 .3H 2 O, 5.0g Zn(NO 3 ) 2 .6H 2 O, 49.9 g TEOS and 44.8 g ethanol, 47.9 g water, and 3.6 g PEG400 were mixed in a beaker, stirred at room temperature for 2 h, poured into a plastic bottle and sealed, and formed a gel after about 4 days, cut into thin slices and measured with pH = Soak in ammonia water at about 11, and then at 75 o Evaporate to dryness on a C water bath, then slowly raise the temperature to 100 o C to dry for 24h, take it out and wash with water until the filtrate is colorless, then slowly rise to 120 o C dried for 12h, then slowly increased to 500 o C is calcined for 1 hour to obtain catalyst C. Catalyst evaluation is the same as embodiment 1, and reduction temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com