Cobalt-based Fischer-Tropsch synthetic catalyst as well as preparation method and application thereof

A technology for synthesis of catalysts and tropos, which is applied in the direction of chemical instruments and methods, preparation of liquid hydrocarbon mixtures, physical/chemical process catalysts, etc., to achieve the effects of high strength and wear resistance, stable structure and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

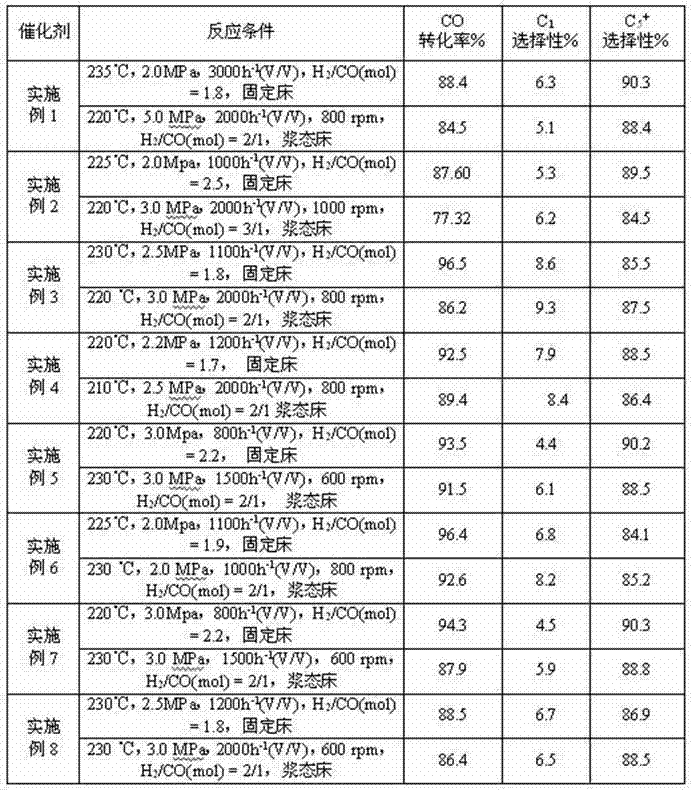

Examples

Embodiment 1

[0032]Prepare a certain amount of 1mol / L aluminum sulfate aqueous solution, and add the hydrolysis agent ammonia water into the solution at 0.2mol / L, keep the temperature at 70°C under the microwave power of 2000W, and keep the time for 90min, then press the sol agent and aluminum source Add peptizer HNO at a molar ratio of 0.01:1 3 , stirred and refluxed to a transparent sol, kept in a water bath for 3 hours, and aged at room temperature for 12 hours to obtain a gel. The gel was dried in a microwave drying oven at 120°C for 1 hour, and then the dried gel was placed in a microwave temperature-programmed oven at a heating rate of 0.5°C / min and calcined at 350°C for 10 hours to obtain a catalyst carrier.

[0033] Weigh Co(NO 3 ) 2 ·6H 2 O, NH 4 VO 3 and RuCl 3 ·3H 2 O, measure deionized water according to the equal-volume impregnation method, prepare a mixed salt solution and impregnate the above-mentioned carrier for 5 hours, then dry at 100°C for 6 hours, and finally ba...

Embodiment 2

[0036] Prepare a certain amount of 0.1mol / L aluminum isopropoxide aqueous solution, and add the hydrolysis agent HCl into the solution at 0.01mol / L, keep the temperature at 75°C under the microwave power of 20W, and keep the time for 90min, then press the sol agent Add the peptizer HNO at a molar ratio of 0.05:1 to the aluminum source 3 , stirred and refluxed at a microwave power of 200W until a transparent sol was maintained for 3h, and then aged at room temperature for 12h to obtain a gel. The gel was dried in a drying oven at 100°C for 6 hours, and then the dried gel was placed in a temperature-programmed furnace at a heating rate of 1°C / min and calcined at 350°C for 10 hours to obtain a catalyst carrier.

[0037] Weigh Co(NO 3 ) 2 ·6H 2 O, Cu(NO 3 ) 2 ·3H 2 O and RuCl 3 ·3H 2 O, take deionized water according to the equal-volume impregnation method, prepare a mixed salt solution and impregnate it on the above-mentioned carrier for 5 hours, then dry it at 100°C for ...

Embodiment 3

[0040] Prepare a certain amount of 0.5mol / L sodium aluminate aqueous solution, and add the hydrolyzing agent ammonia water into the solution at 0.15mol / L, keep the temperature at 65°C, and keep the time for 60min. 0.1:1 add peptizer HNO 3 , stirred and refluxed until a transparent sol was maintained for 3 hours, and then aged at room temperature for 12 hours to obtain a gel. The gel was dried in a drying oven at 105°C for 6 hours, then the dry gel was placed in a temperature-programmed microwave oven at a heating rate of 2°C / min, and calcined at 350°C for 10 hours to obtain a catalyst carrier.

[0041] Weigh Co(NO 3 ) 2 ·6H 2 O, LaCl 3 ·7H 2 O and IrCl 3 ·3H 2 O, measure deionized water according to the equal-volume impregnation method, prepare a mixed salt solution and impregnate the above carrier for 5 h, then dry at 100 °C for 6 h, and finally roast at 250 °C for 15 h, with a heating rate of 3 °C / min, the catalyst was prepared. The final catalyst weight is Co 3 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com