Supported phosphotungstic acid catalyst and preparation thereof, and preparation method of methyl acetate

A phosphotungstic acid and catalyst technology, applied in the field of supported phosphotungstic acid catalyst and its preparation, can solve the problems of complex post-treatment process, many side reactions, equipment corrosion, etc., and achieve low price, less side reactions, and no corrosion of equipment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

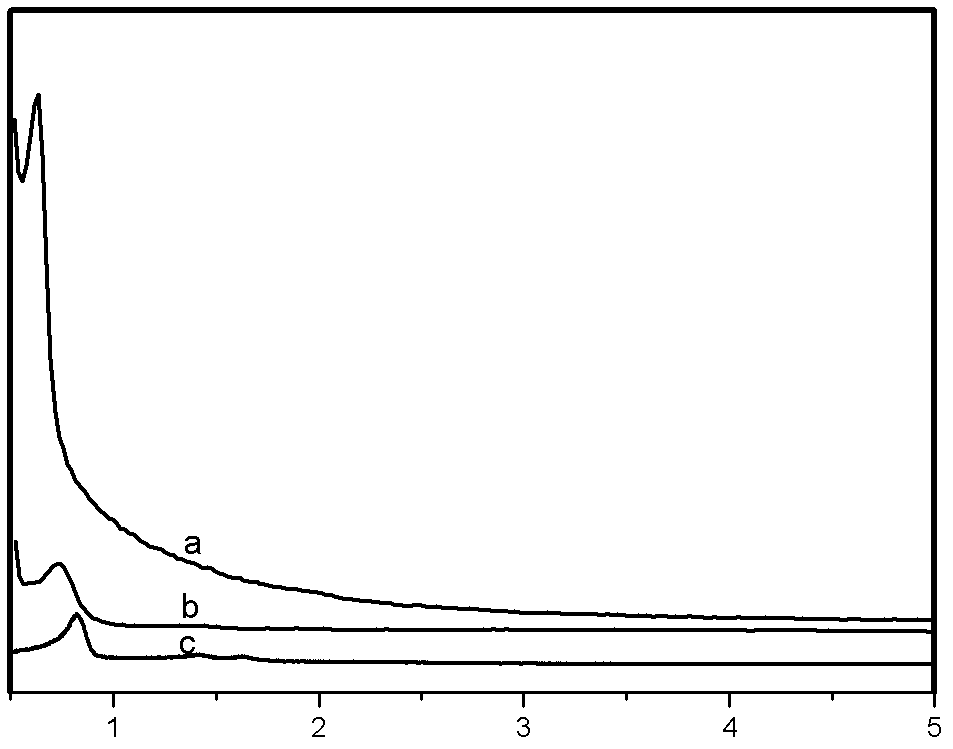

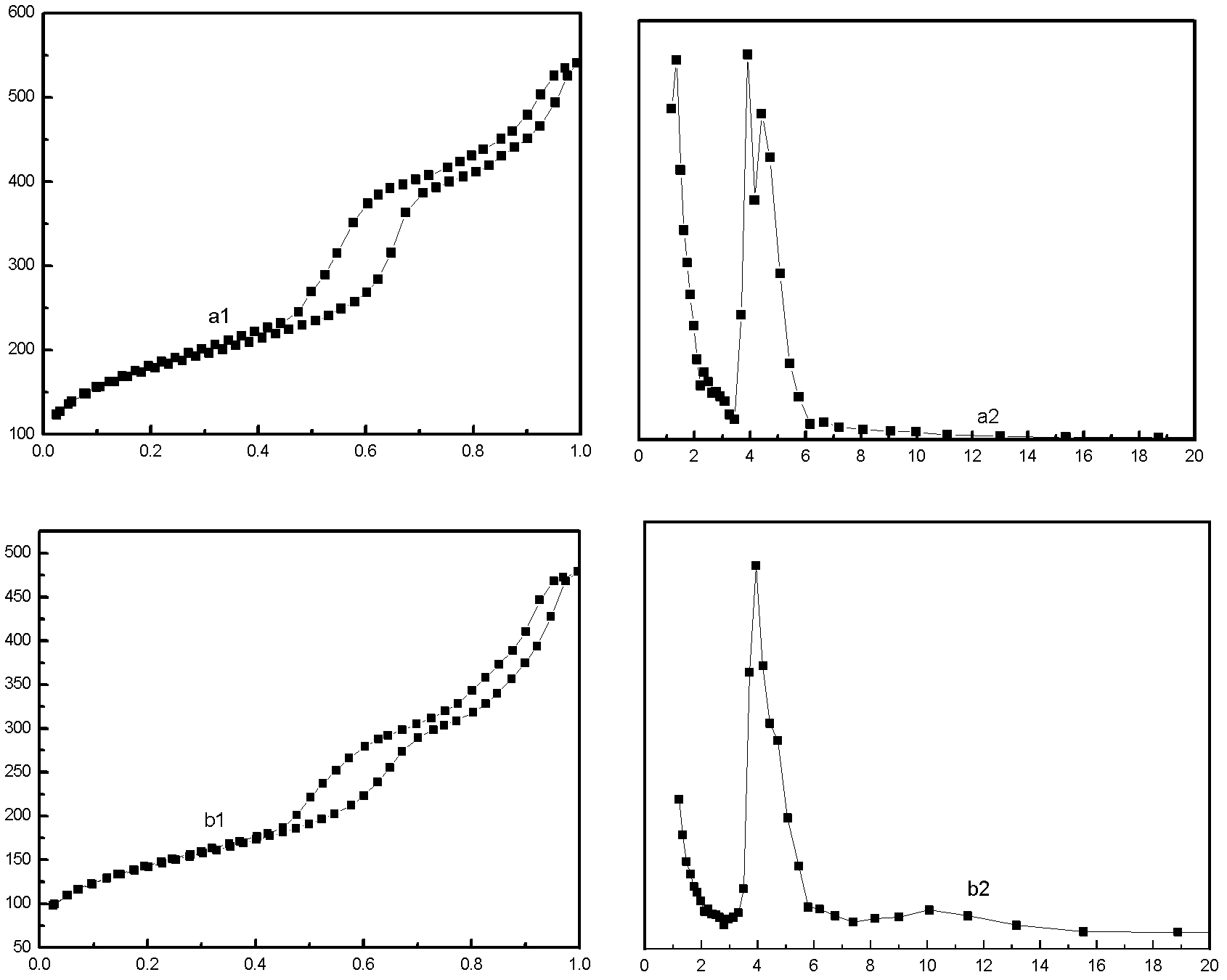

[0032] According to one embodiment of the present invention, the preparation method of the supported phosphotungstic acid catalyst comprises: stirring a spherical mesoporous silica carrier, methanol and phosphotungstic acid at a temperature of 100-150° C. for 0.5-72 hours, and then pumping Filtration, in molar ratio, spherical mesoporous silica carrier (calculated as silica): methanol; phosphotungstic acid=1: 10-50: 0.005-0.1, preferably spherical mesoporous silica carrier: methanol: phosphorus Tungstic acid = 1: 15-25: 0.065-0.095, more preferably a spherical mesoporous silica carrier: methanol: phosphotungstic acid = 1: 18.02: 0.08, and then dry the solid with nitrogen to obtain a carrier of phosphotungstic acid Spherical mesoporous silica.

[0033] According to the present invention, the size of the spherical mesoporous silica can be changed in a wide range. Preferably, the average particle diameter of the spherical mesoporous silica carrier is 20-80 microns, and the specif...

specific Embodiment approach

[0034] According to a specific embodiment of the present invention, the preparation method of the supported phosphotungstic acid catalyst comprises the following steps:

[0035] In the first step, the three-block copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene and N,N-dimethylformamide (DMF) are added to aqueous hydrochloric acid, and the molar feed ratio is

[0036] Tri-block copolymer polyethylene oxide-polyoxypropylene-polyoxyethylene: N, N-dimethylformamide (DMF): water: hydrogen chloride = 1: 300-700: 10000-20000: 100-500, preferably 1: 550-650: 10000-13000: 150-480, particularly preferably 1: 596: 11411: 326, wherein, the molar number of polyethylene oxide-polyoxypropylene-polyoxyethylene is based on polyethylene oxide-polyoxypropylene- The average molecular weight of polyethylene oxide was calculated as,

[0037] Stir at 25-60°C until dissolved;

[0038] In the second step, add ethyl orthosilicate to the solution obtained in the previous step, stir at 25-60...

Embodiment 1

[0058] This example is used to illustrate the supported phosphotungstic acid catalyst and its preparation method according to the present invention.

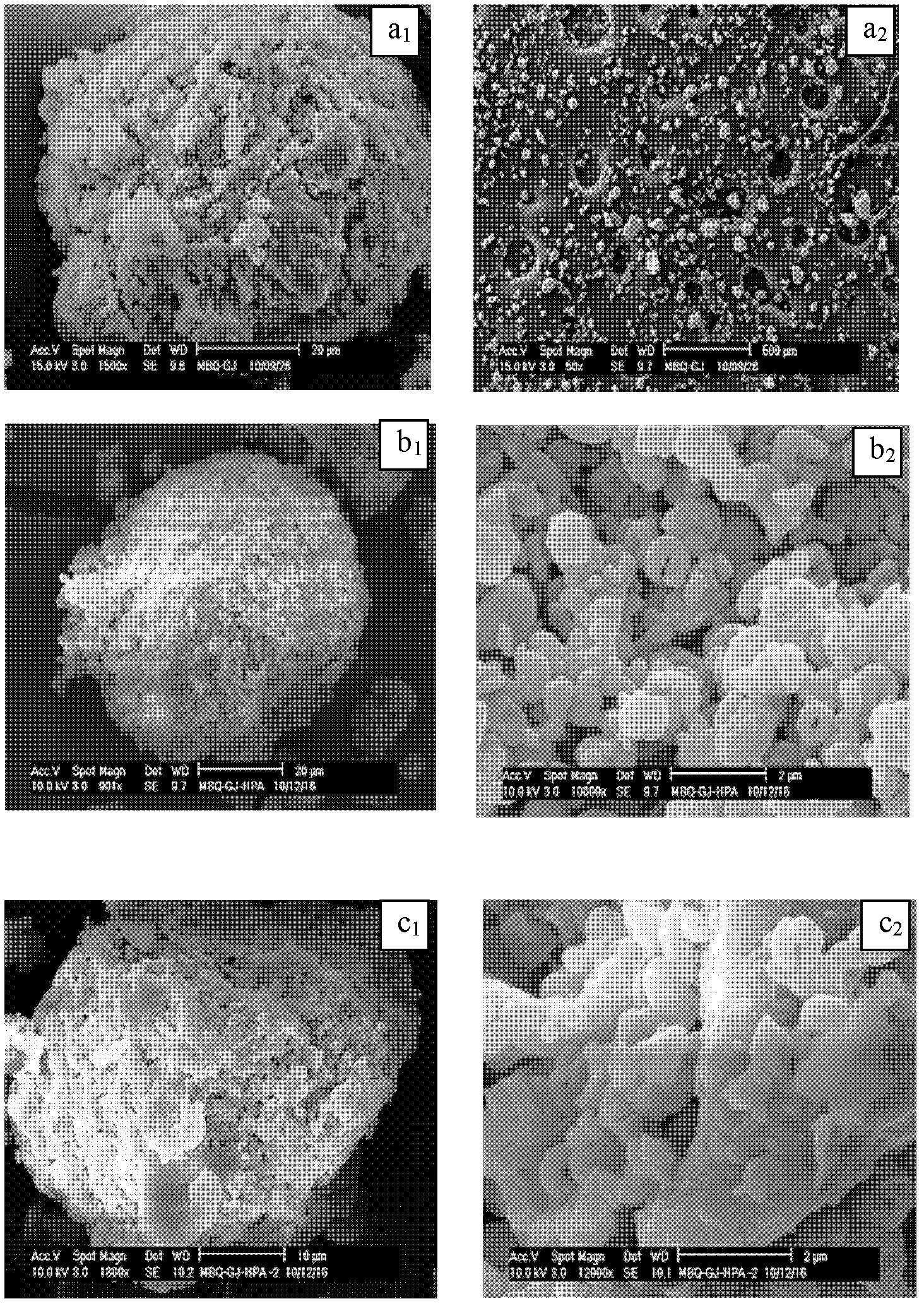

[0059] Add 2.0 grams of P123 and 15 grams of N,N-dimethylformamide (DMF) and 64ml of water to 11.2 grams of 37% hydrochloric acid, stir at 40°C until P123 is completely dissolved; then add 4.45 grams of orthosilicic acid Add ethyl ester to the above solution and stir at 40°C for 1 hour, then add 1 gram of industrial ES955 silica gel (particle diameter is 15-60 microns), crystallize at 120°C for 30 hours, filter, wash and dry to obtain the original powder Porous material: The original powder mesoporous material was calcined in a muffle furnace at 600°C for 24 hours to remove the template agent and obtain spherical mesoporous silica (named GJ-MBQ).

[0060] The above-mentioned spherical mesoporous silica GJ-MBQ was calcined at 400° C. for 10 hours under the protection of nitrogen to remove hydroxyl groups and residual moisture, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com