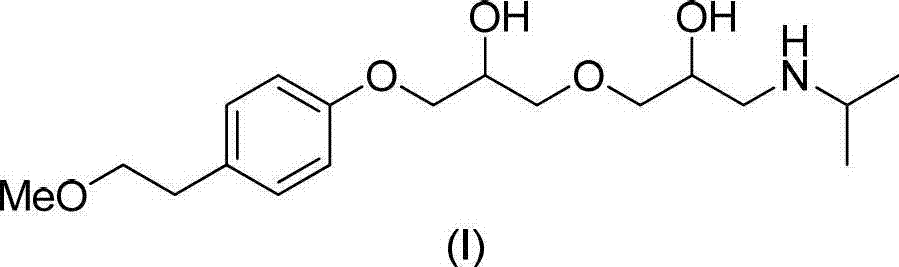

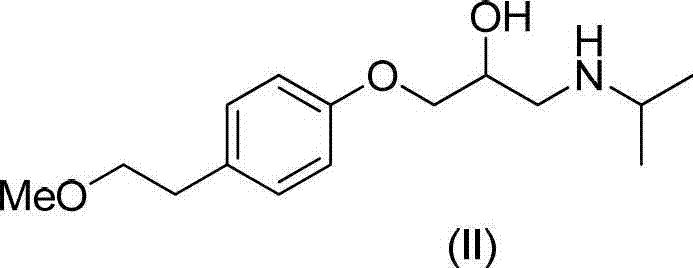

Preparation method of related substance J of metoprolol

A compound, the technology of methoxyethyl, is applied in the field of preparation of metoprolol related substance J, which can solve the problems such as no synthesis report

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

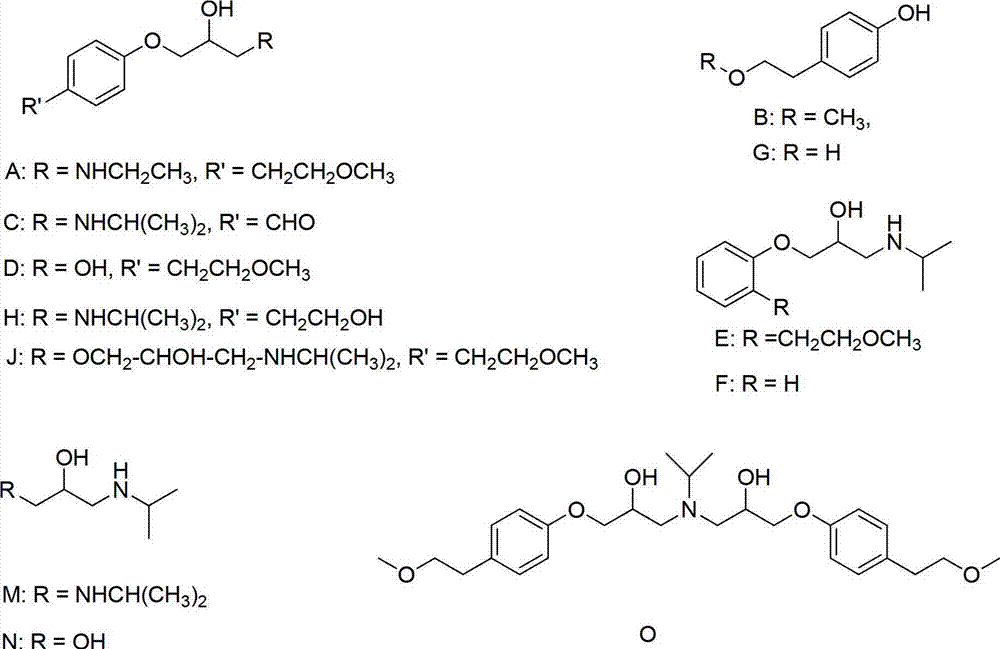

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Synthesis of 1-(2,3-epoxypropoxy)-4-(2-methoxyethyl)benzene (IV)

[0040] Add 20.0g of compound (Ⅲ), 200mL of 3% sodium hydroxide aqueous solution, 2.0g of tetrabutylammonium bromide and 18.0g of epichlorohydrin into the reaction flask, raise the temperature to 70°C, stir for 5h, and the reaction is complete. 200 mL of ethyl acetate was added for extraction, the liquid was separated, and the ethyl acetate was removed under reduced pressure to obtain 27.0 g of a yellow liquid, which was directly carried out to the next reaction.

Embodiment 2

[0041]Example two: Synthesis of 1-allyloxy-3-[4-(2-methoxyethyl)phenoxy]-2-propanol (Ⅴ)

[0042] Add the compound (IV) prepared in Example 1 and 150 mL of allyl alcohol into the reaction flask, control the temperature at 0-10° C., and add 6.5 g of 60% sodium hydrogen in batches. After the addition, the temperature was raised to 25° C. and stirred for 3 h, and the reaction was completed. Add 100mL of 2N hydrochloric acid to quench the reaction, add 100mL of dichloromethane for extraction, and separate the organic layer. The aqueous phase was extracted once more with 100 mL of dichloromethane. The organic layers were combined, washed once with saturated brine, and dried over anhydrous sodium sulfate. The solvent was removed under reduced pressure to obtain 34.5 g of oil, which was directly put into the next reaction.

Embodiment 3

[0043] Example Three: Synthesis of 1-[4-(2-methoxyethyl)phenoxy]-3-(2,3-epoxypropoxy)-2-propanol (Ⅵ)

[0044] Add the compound (V) prepared in Example 2 and 350 mL of dichloromethane into the reaction flask, add 51.3 g of m-chloroperoxybenzoic acid, and react at room temperature for 20 h, and the reaction is complete. Filter and wash the filter cake once with dichloromethane. Combine the filtrates, add 150mL10% sodium sulfite solution for washing, and separate the organic layer. The organic layer was washed once with 150 mL of saturated sodium bicarbonate and 150 mL of water. The organic phase was dried, and the solvent was concentrated to obtain 35.0 g of oil, which was directly put into the next reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com