Wedelia prostrate polysaccharide as well as preparation method and application of wedelia prostrate polysaccharide

A technology of polysaccharide and chrysanthemum halothi, applied in application, tobacco, food science and other directions, can solve the problems of high cost, low yield, low purity, etc., achieve simple operation, high impurity removal rate, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Crush the dried whole-plant sample of Chrysanthemum chrysanthemum to 40 mesh, add a certain amount of distilled water according to the ratio of solid to liquid (mass ratio) 1:20, extract with boiling water at 100°C for 2 times, each time for 3 hours, and combine the 2 extracts to obtain the total Extraction solution;

[0043] After the total extract was cooled, it was centrifuged at a high speed (10,000 rpm) at 25°C for 15 minutes and vacuum filtered, then concentrated in vacuum to 1 / 10 of the volume of the original total extract, and an aqueous ethanol solution with a volume fraction of 95% was added to the concentrate to make The volume fraction of ethanol in the system reaches 50%, stir, stand still for 10 hours, centrifuge, collect the precipitate, freeze-dry to obtain the crude polysaccharide;

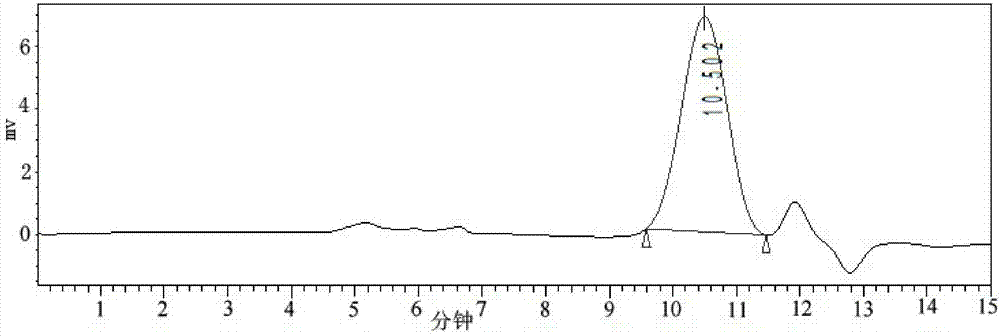

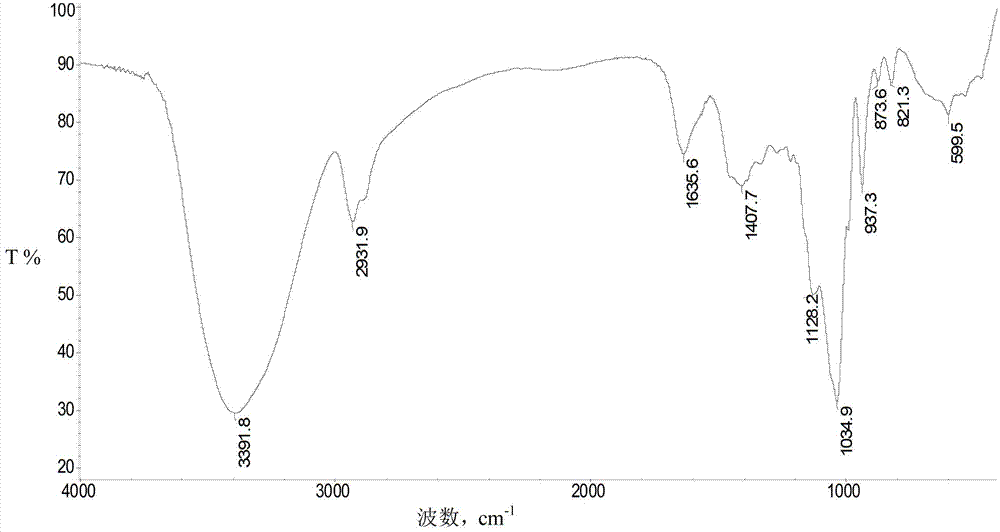

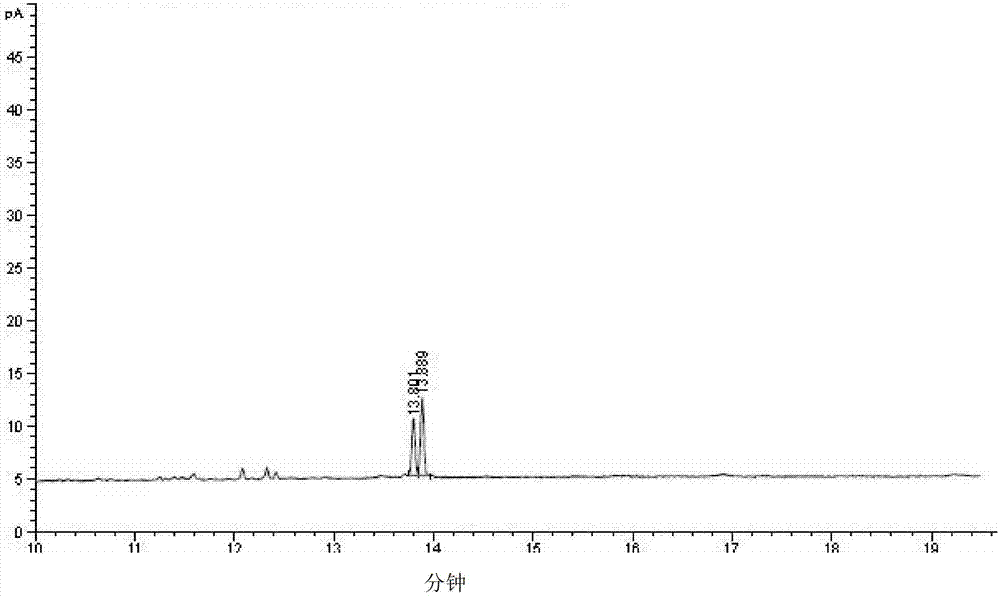

[0044] Dissolve the crude polysaccharide in water, put it on a DEAE-Sepharose Fast Flow ion column (column type is XK 26×100cm diethylaminoethyl sepharose ion exchange colu...

Embodiment 2

[0048] Crush the dried sample of the whole plant of Chrysanthemum chrysanthemum to 40 mesh, add a certain amount of distilled water according to the ratio of solid to liquid (mass ratio) 1:30, extract with boiling water at 100°C for 2 times, each time for 3 hours, and combine the 2 extracts to obtain the total Extraction solution;

[0049] After the total extract was cooled, it was centrifuged at a high speed (10,000 rpm) at 25°C for 15 minutes and vacuum filtered, then concentrated in vacuum to 1 / 20 of the volume of the original total extract, and an aqueous ethanol solution with a volume fraction of 95% was added to the concentrate to make The volume fraction of ethanol in the system reaches 60%, stir, stand still for 10 hours, centrifuge, collect the precipitate, freeze-dry to obtain the crude polysaccharide;

[0050] Dissolve the crude polysaccharide in water, put it on a DEAE-Sepharose Fast Flow ion column (column type is XK 26×100cm) ion exchange column, elute with disti...

Embodiment 3

[0056] Grind the dried whole plant of Chrysanthemum chrysanthemum to 80 mesh, add a certain amount of distilled water according to the ratio of solid to liquid (mass ratio) 1:40, extract with boiling water at 100°C for 2 times, each time for 3 hours, and combine the 2 extracts to obtain the total Extraction solution;

[0057] After the total extract was cooled, it was centrifuged at a high speed (10,000 rpm) at 25°C for 15 minutes and vacuum filtered, then concentrated in vacuum to 1 / 10 of the volume of the original total extract, and an aqueous ethanol solution with a volume fraction of 95% was added to the concentrate to make The volume fraction of ethanol in the system reaches 65%, stir, stand still for 10 hours, centrifuge, collect the precipitate, freeze-dry to obtain the crude polysaccharide;

[0058] Dissolve the crude polysaccharide in water, put it on a DEAE-Sepharose Fast Flow ion column (column type is XK 26×100cm) ion exchange column, elute with distilled water, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com