Preparation method of strong-acid-resistant strong-base-resistant polyether sulfone tubular ultrafiltration dry membrane

A polyethersulfone and strong acid-resistant technology, which is used in the preparation of tubular ultrafiltration dry membranes, can solve the problem of destroying the normal curing and sealing of the adhesive at the end of the membrane module, affecting the membrane permeability and mechanical strength, and unfavorable component processing. Manufacturing and transportation problems, to achieve the effect of reducing the cost and risk of storage and transportation, overcoming easy pollution and blockage, and facilitating storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

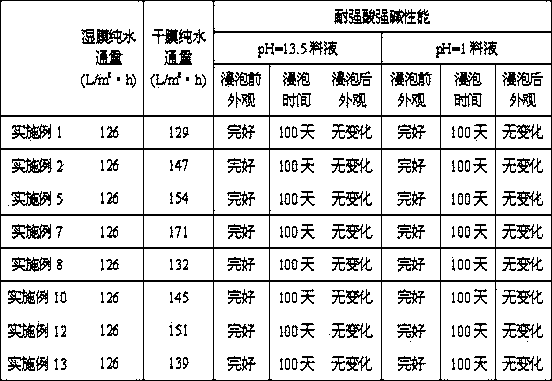

Examples

Embodiment 1

[0024] Immerse the strong acid and strong alkali resistant polyethersulfone tubular ultrafiltration wet membrane in purified water at a temperature of 35°C for 20 minutes, and then directly immerse it in a temperature of 25°C, composed of 0.2% by mass polyoxyethylene alkylbenzene sulfonate ammonium salt, 30% glycerin, 0.5% formaldehyde and 69.3% purified water in the film dry state treatment solution, soaked continuously for 4 days, then took it out and dried it naturally for 12 hours at the temperature of 25°C and the relative humidity of 88%, that is, it was used for Strong acid and strong base polyethersulfone tubular ultrafiltration dry membrane.

Embodiment 2

[0026] Soak the strong acid and strong alkali resistant polyethersulfone tubular ultrafiltration wet membrane in deionized water at a temperature of 50°C for 30 minutes, and then directly immerse it in a temperature of 30°C with a mass percentage of 0.5% alkylbenzene polyoxyethylene ether, 45% Glycerin, 0.2% isothiazolinone and 54.3% deionized water were used to dry the film, soaked continuously for 5 days, then took it out and dried it naturally for 12 hours in an environment with a temperature of 25 ° C and a relative humidity of 88%. It is suitable for strong acid and alkali resistant polyethersulfone tubular ultrafiltration dry membrane.

Embodiment 3

[0028] Soak the strong acid and strong alkali resistant polyethersulfone tubular ultrafiltration wet membrane in distilled water at a temperature of 65°C for 25 minutes, then directly immerse it in a temperature of 30°C, composed of 0.35% sodium lauryl sulfate, 50% glycerin, 1.0% sodium bisulfite and 48.65% distilled water in the film dry state treatment solution, soaked continuously for 3 days, then took it out and dried it for 2 hours in an environment with a temperature of 80°C and a relative humidity of 20%. Polyethersulfone tubular ultrafiltration dry membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com