Rubber-plastic modified environmental protection material and preparation method thereof

An environmentally friendly material and modification technology, which is applied in the field of shoe rubber, can solve problems such as wear resistance, aging resistance and heat resistance, failure to master raw materials and additives, and long degradation time of waste materials, etc., to achieve Improvement of physical and chemical properties, changes in chemical stability and thermal stability, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

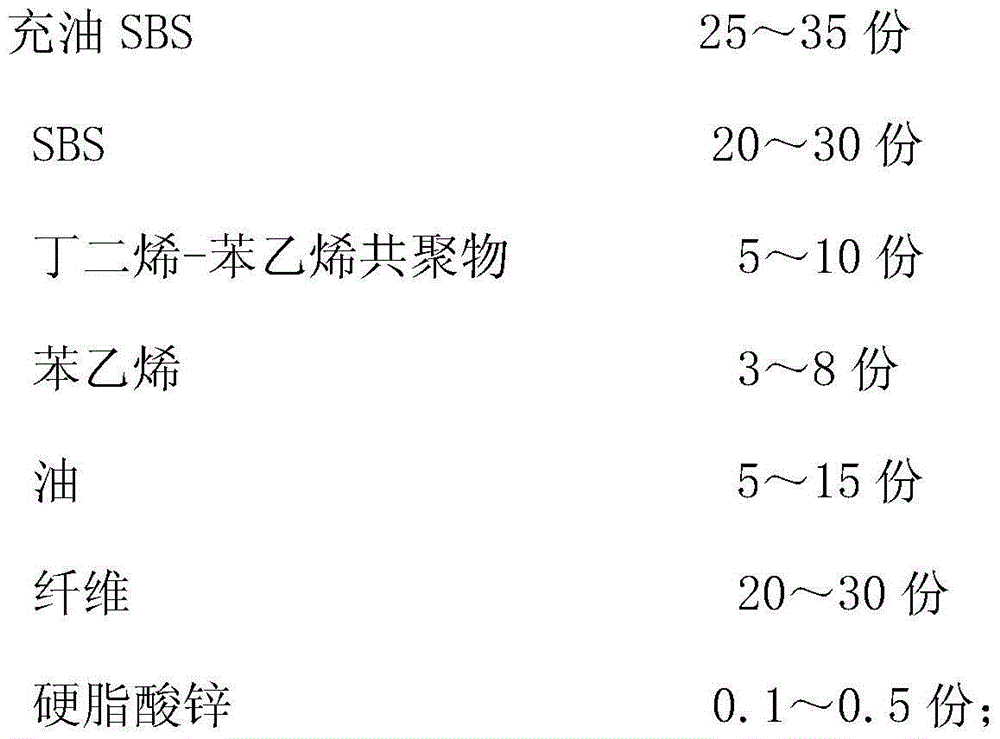

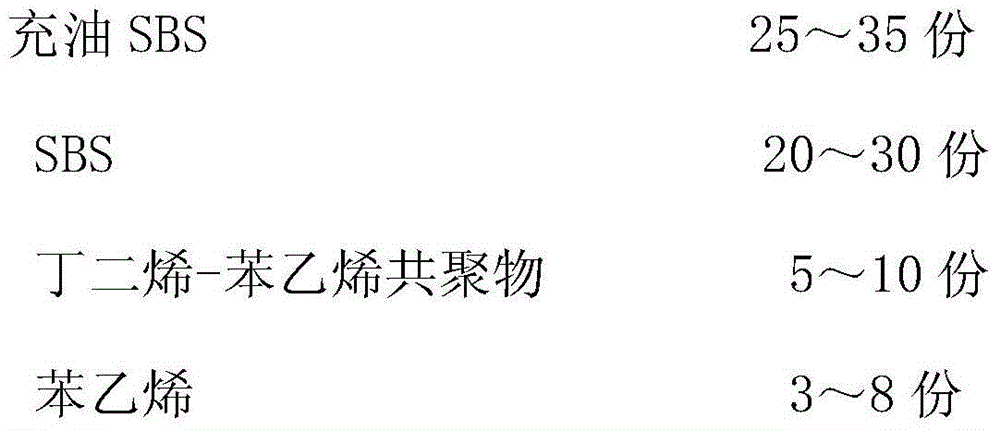

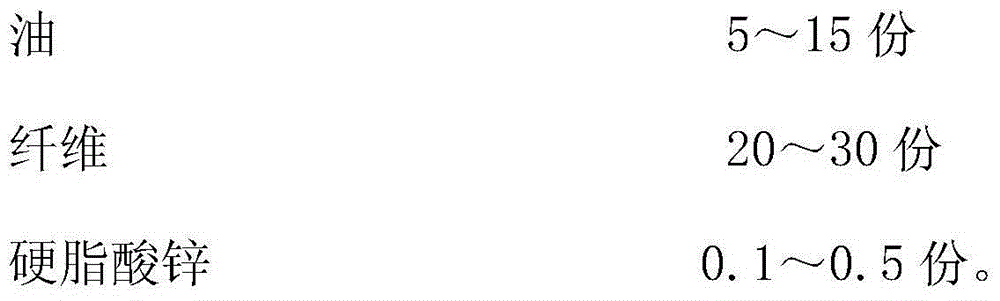

[0027] A rubber-plastic modified environmental protection material, including oil-extended SBS 35Kg, SBS 20Kg, butadiene-styrene copolymer 5Kg, styrene 4.5Kg, naphthenic oil 5Kg, bamboo fiber 30Kg, zinc stearate 0.5Kg.

[0028] The method for preparing the rubber-plastic modified environmental protection material includes the following preparation steps:

[0029] Step A. Ball mill the amount of SBS, styrene, oil, fiber, and zinc stearate first, then send them to an internal mixer or kneader for internal mixing or kneading at 80°C for 8 minutes, and finally discharge, cool, Broken to obtain mixture I;

[0030] Step B. Transfer the mixture I to the reactor, raise the temperature to 110°C, slowly add oil-extended SBS and butadiene-styrene copolymer, stir and knead for 15 minutes to obtain the mixture II;

[0031] Step C, put the mixture II into an extruder to melt and extrude at 98°C, then cool, cut into pellets, and dry to obtain the rubber-plastic modified environmental protec...

Embodiment 2

[0033] A rubber-plastic modified environmental protection material, including 30Kg of oil-filled SBS, 25Kg of SB, 8Kg of butadiene-styrene copolymer, 5Kg of styrene, 6.7Kg of naphthenic oil, 25Kg of straw fiber, and 0.3Kg of zinc stearate.

[0034] The method for preparing the rubber-plastic modified environmental protection material includes the following preparation steps:

[0035] Step A, ball mill the amount of SBS, styrene, oil, fiber, and zinc stearate first, then send it to an internal mixer or kneader for internal mixing or kneading at 95°C for 6 minutes, and finally discharge, cool, Broken to obtain mixture I;

[0036] Step B. Transfer the mixture I to the reactor, raise the temperature to 110°C, slowly add oil-extended SBS and butadiene-styrene copolymer, stir and knead for 10 minutes to obtain the mixture II;

[0037] Step C, put the mixture II into an extruder to melt and extrude at 110°C, then cool, cut into pellets, and dry to obtain the rubber-plastic modified ...

Embodiment 3

[0039]A rubber-plastic modified environmental protection material, including oil-extended SBS 25Kg, SBS 30Kg, butadiene-styrene copolymer 10Kg, styrene 4.9Kg, naphthenic oil 10Kg, jute fiber 20Kg, zinc stearate 0.1Kg.

[0040] The method for preparing the rubber-plastic modified environmental protection material includes the following preparation steps:

[0041] Step A. Ball mill the amount of SBS, styrene, oil, fiber, and zinc stearate first, and send them to a banbury mixer or kneader, banbury or knead at 85°C for 7 minutes, then discharge and cool , crushed to obtain mixture I;

[0042] Step B. Transfer the mixture I to the reactor, raise the temperature to 114°C, slowly add oil-extended SBS and butadiene-styrene copolymer, stir and knead for 14 minutes to obtain the mixture II;

[0043] Step C, put the mixture II into an extruder to melt and extrude at 100°C, then cool, cut into pellets, and dry to obtain the rubber-plastic modified environmental protection material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com