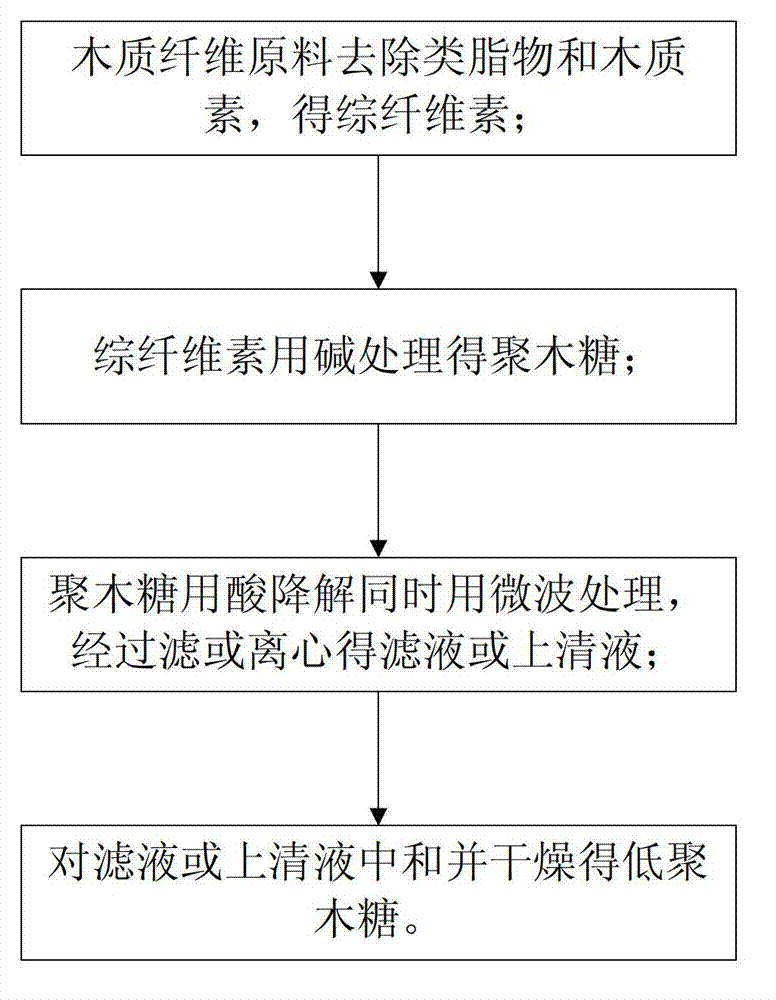

Microwave-assisted xylo-oligosaccharide preparation method

A xylo-oligosaccharide and microwave-assisted technology, which is applied in the field of microwave-assisted preparation of xylo-oligosaccharide, can solve the problems of difficult separation and purification, high production cost, and long time consumption, and achieve easy-to-obtain raw materials, large amounts of raw materials, and high product value high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of microwave-assisted method for preparing xylo-oligosaccharides of the present embodiment comprises the following steps:

[0037] a. Extraction of xylan:

[0038] (a1) Weigh 100 g of 40-60 mesh bamboo powder, and reflux with 500 ml of toluene-ethanol (2:1, v / v) for 12 hours to remove lipids in the raw material;

[0039] (a2) Remove lignin from the degreased bamboo powder with 2000ml of 7.5% sodium chlorite solution at 75°C and pH 3.8 for 2 hours to prepare bamboo cellulose;

[0040] (a3) Extract cellulose with 2000ml 10% NaOH at room temperature for 12 hours, filter, adjust the pH of the filtrate to 5.5 with 6M HCl, and dialyze in a dialysis bag with a molecular weight cut-off of 3500Da for 3 days;

[0041] (a4) Freeze-drying to obtain xylan, the temperature is -40°C, the vacuum degree is 200mba, and the time is 24h;

[0042] b. Preparation of xylo-oligosaccharides: the xylo-oligosaccharides obtained in step a are added to 0.2M sulfuric acid, the solid-liquid ...

Embodiment 2

[0047] a. Extraction of xylan:

[0048] (a1) Weigh 100g of Populus tomentosa powder of 50-80 mesh, and reflux with 500ml of toluene-ethanol (2:1, v / v) for 6h to remove lipids in the raw material;

[0049] (a2) Degreasing poplar tomentosa powder with 2000ml of sodium chlorite solution with a mass fraction of 7.5% at 75°C and pH 3.8 for 2 hours to prepare poplar tomentosa cellulose;

[0050](a3) Extract cellulose with 2500ml 10% KOH at room temperature for 8 hours, filter, adjust the pH of the filtrate to 5.5 with acetic acid, and dialyze in a dialysis bag with a molecular weight cut-off of 3800Da for 3 days;

[0051] (a4) To obtain xylan by freeze-drying, the temperature is -50°C, the vacuum degree is 400mba, and the time is 30h;

[0052] b. Preparation of xylo-oligosaccharides: Add the xylo-oligosaccharides obtained in step a into 0.2M oxalic acid, the ratio of solid to liquid (g / ml) is 1:30, degrade at a temperature of 80°C for 40 minutes, and use a power of 800W at the same...

Embodiment 3

[0057] a. Extraction of xylan:

[0058] (a1) Weigh 100g of 40-60 mesh wheat straw powder, and reflux with 500ml of toluene-ethanol (2:1, v / v) for 9 hours to remove lipids in the raw material;

[0059] (a2) Remove lignin from defatted wheat straw powder with 2000ml of 6% sodium chlorite solution at 77°C and pH 3.6 for 2 hours to prepare wheat straw cellulose;

[0060] (a3) Use 2300ml of 8% KOH to extract the cellulose at room temperature for 10 hours, filter, adjust the pH of the filtrate to 5.5 with acetic acid, and then dialyze in a dialysis bag with a molecular weight cut-off of 2000Da for 2 days;

[0061] (a4) Xylan was obtained by vacuum drying at a temperature of 30°C and a vacuum of 0.8 MPa for 48 hours;

[0062] b. Preparation of xylo-oligosaccharides: Add the xylo-oligosaccharides obtained in step a into 0.1M formic acid, the ratio of solid to liquid (g / ml) is 1:25, degrade at a temperature of 90°C for 60 minutes, and use a power of 800W at the same time microwave tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com