Cataplasm substrate and application thereof

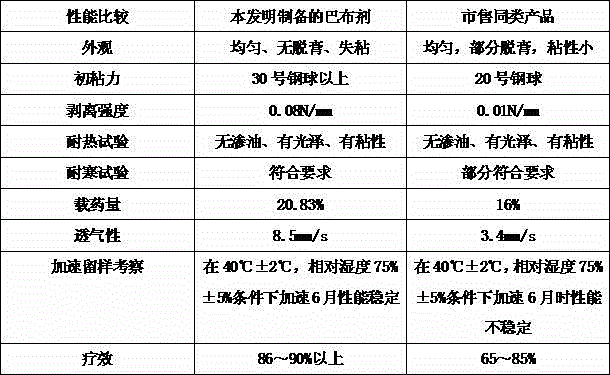

A poultice and matrix technology, which is applied to the poultice matrix and its application field, can solve the problems of poor sticking property, insufficient viscoelasticity, easy slipping and the like, and achieves fast onset of medicinal properties, good compliance, Use good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] When the present invention is implemented, it can be calculated by the following weight percentages: polyacrylic acid 4.2%, sodium carboxymethyl cellulose 4%, polyvinylpyrrolidone 4%, polyethylene oxide 1.5%, glycerin 26%, purified water 58.5%, glycerin Aluminum hydroxyaluminum 0.1%, disodium edetate 0.15%, tartaric acid 0.15%, crospovidone 1% and Genma BP 0.4%, among them, (1) sodium carboxymethyl cellulose, poly Add vinylpyrrolidone and polyethylene oxide into purified water and heat to dissolve, then add tartaric acid and Genma BP, mix and stir to form a water phase, and set aside; The polyvidone is mixed and stirred evenly to form an oil phase, and the water phase and the oil phase are mixed together, and stirred evenly to obtain the product.

[0014] Also by weight: 420g polyacrylic acid, 400g sodium carboxymethylcellulose, 400g polyvinylpyrrolidone, 150g polyethylene oxide, 2600g glycerin, 5850g purified water, 10g aluminum glycolate, 15g disodium edetate, tartari...

Embodiment 2

[0016] When the present invention is implemented, it is calculated by the following percentages by weight: 4.8% polyacrylic acid, 2.5% sodium carboxymethyl cellulose, 4% polyvinylpyrrolidone, 30% glycerin, 55.79% purified water, 0.06% aluminum glycylate, hydrogen Made of 0.4% alumina, 0.1% ethylenediaminetetraacetic acid, 0.2% tartaric acid, 2% silicon dioxide and 0.15% jalandan, among which, (1) first add sodium carboxymethylcellulose and polyvinylpyrrolidone to purify Heat to dissolve in water, then add tartaric acid and galadan, mix and stir evenly to form a water phase, and set aside; (2) Mix glycerin, polyacrylic acid, aluminum glycolate, aluminum hydroxide, ethylenediaminetetraacetic acid and silicon dioxide For the oil phase, mix the water phase and the oil phase together, stir evenly, and you get it.

[0017] Also by weight: 480g polyacrylic acid, 250g sodium carboxymethylcellulose, 400g polyvinylpyrrolidone, 3000g glycerin, 5579g purified water, 6g aluminum gl...

Embodiment 3

[0019] When the present invention is implemented, it is calculated by the following weight percentages: polyacrylic acid 8%, gelatin 3.2%, carbomer 2%, propylene glycol 30%, purified water 54.37%, aluminum chloride 0.3%, ethylenediaminetetraacetic acid tetra 0.18% sodium, 0.25% citric acid, 1.5% sodium carboxymethylcellulose and 0.2% methyl paraben, among which (1) add gelatin and carbomer to purified water and heat to dissolve, then add citric acid , methyl paraben and stir evenly to form a water phase, and set aside; (2) Mix propylene glycol, polyacrylic acid, aluminum chloride, tetrasodium edetate and sodium carboxymethylcellulose to form an oil phase, and The water phase and the oil phase are mixed together and stirred evenly, that is to say.

[0020] Also by weight: 800g polyacrylic acid, 320g gelatin, 200g carbomer, 3000g propylene glycol, 5437g purified water, 30g aluminum chloride, 18g tetrasodium edetate, 25g citric acid, 150g sodium carboxymethyl cellulose Made ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com