Effective method for doping nitrogen into carbon nanotips

A cutting-edge and effective technology of carbon nanometer, applied in the direction of nanocarbon, nanotechnology, nanotechnology, etc., can solve problems such as influence and adverse effects, and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

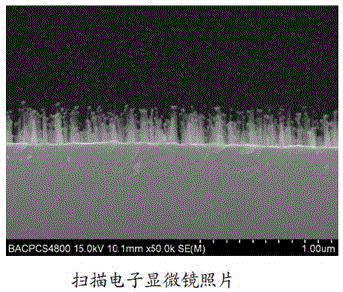

[0038] Embodiment 1: A kind of effective doping method of nitrogen in carbon nano tip, deposit a layer of gold film on Si substrate as catalyst layer, with CH 4 、H 2 and N 2 As the reaction gas, an amorphous carbon nanotip was prepared; the thickness of the gold film was about 10 nm, the substrate temperature was 850 °C, CH 4 The flow rate is 20sccm (sccm means that the gas flows through 1cm per minute under standard conditions 3 ), H 2 The flow rate is 70sccm, N 2 The flow rate is 30 sccm, the working pressure of the reaction chamber is 2000 Pa, and the bias current is 160 mA.

[0039] Figure 3 ~ Figure 7 The scanning electron micrograph of the photo shows that the carbon nanotip is formed, and the gold particle is located on the tip of the tip. Transmission scanning electron micrographs show that the formed carbon nanotips are amorphous. X-ray photoelectron spectroscopy revealed nitrogen doping at the amorphous carbon nanotips. According to the fitting of the X-ray ...

Embodiment 2

[0040] Embodiment 2: A kind of effective doping method of nitrogen in carbon nano-tip, deposit a layer of gold film on Si substrate as catalyst layer, with CH 4 、H 2 and N 2 As the reaction gas, an amorphous carbon nanotip was prepared; the thickness of the gold film was about 10 nm (nm is nanometer), the substrate temperature was 850 °C, CH 4 The flow rate is 20sccm, H 2 The flow rate is 70sccm, N 2 The flow rate is 40 sccm, the working pressure of the reaction chamber is 2000 Pa, and the bias current is 160 mA.

[0041] see Figure 8 ~ Figure 12 , The second embodiment prepares relevant photos and X-ray photoelectron spectra of nitrogen-doped amorphous carbon nano-tips. The scanning electron micrograph shows that carbon nanotips are also formed under this growth condition, with gold particles on top of the tips. Transmission scanning electron micrographs show that the formed carbon nanotips are amorphous. X-ray photoelectron spectroscopy revealed nitrogen doping at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com