Combined carbonaceous reducing agent for smelting metal silicon and preparation method thereof

A combined, reducing agent technology, used in silicon compounds, non-metallic elements, chemical instruments and methods, etc., can solve problems such as unfavorable electrode deep insertion, damage to forest resources and the environment, large consumption, etc., to improve efficiency and product quality. quality, broaden source channels, and enhance the effect of added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0017] Add 2 to 3% of binder to the mixture of clean coal powder and petroleum coke powder, cold press to form pellets, and dry to prepare combined carbonaceous reducing agent pellets.

[0018] The petroleum coke powder contains 85-87% by weight of fixed carbon, 0.4-0.6% of ash, and 10-12.5% of volatile matter.

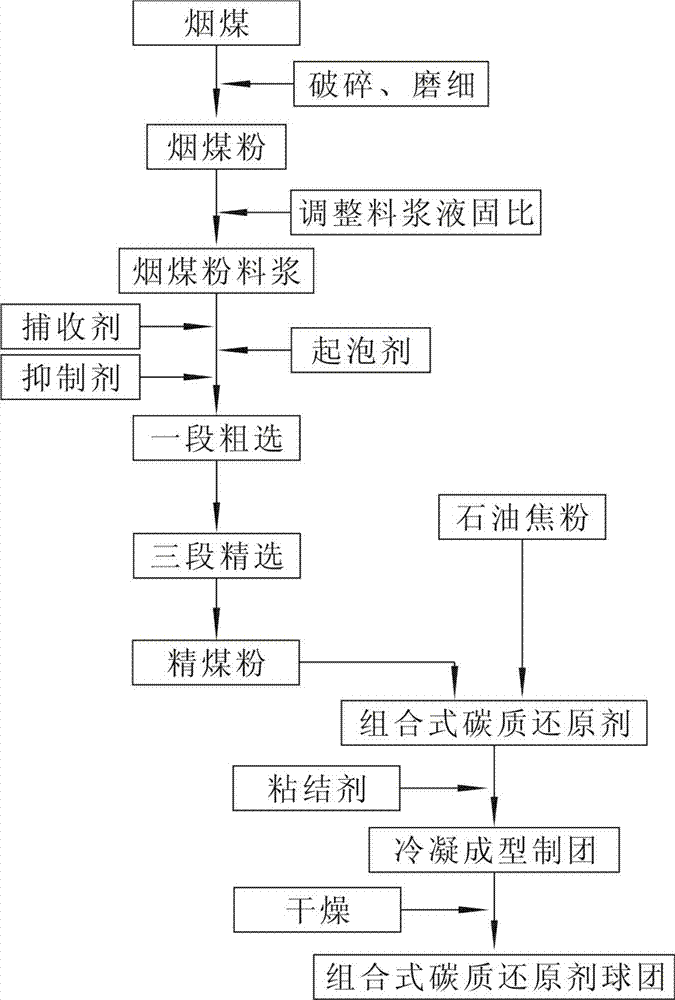

[0019] Such as figure 1 As shown, the preparation method of the combined carbonaceous reducing agent for smelting metal silicon described in the present invention is to mix the clean coal powder obtained by deashing bituminous coal through the oil agglomeration selective flocculation method, and petroleum coke powder. ,Specifically:

[0020] A. Preparation of clean coal powder: crush and finely grind the bituminous coal to a particle size of -74μm~+178μm; adjust the liquid-solid weight ratio of the slurry to 1:3~5, add collectors, inhibitors, foaming agents, and use a section of coarse Clean coal powder is obtained by the flotation method of selection and three-st...

Embodiment 1

[0032] Crush and finely grind the bituminous coal until the particle size is -74μm~+178μm; adjust the liquid-solid weight ratio of the ore slurry to 1:3, add diesel oil, water glass, and No. 2 oil, and adopt the flotation method of one-stage roughing and three-stage beneficiation Clean coal powder: according to the weight ratio of clean coal powder:petroleum coke powder=8:2, clean coal powder and petroleum coke powder are evenly mixed to obtain the combined carbonaceous reducing agent. The obtained clean coal powder contains 76% by weight of fixed carbon, 4% of ash, and 18% of volatile matter, and the used petroleum coke powder contains 85% by weight of fixed carbon, 0.42% of ash, 10% of volatile matter; the combined carbonaceous reductant obtained contains 77.8% by weight of fixed carbon, 3.3% ash, and 16.4% volatile matter.

Embodiment 2

[0034] Crush and finely grind the bituminous coal until the particle size is -74μm~+178μm; adjust the liquid-to-solid weight ratio of the slurry to 1:3, add GH, water glass, and No. 2 oil, and adopt a flotation method of one-stage roughing and three-stage beneficiation Clean coal powder: according to the weight ratio of clean coal powder:petroleum coke powder=7.5:2.5, clean coal powder and petroleum coke powder are evenly mixed to obtain the combined carbonaceous reducing agent. The obtained clean coal powder contains 75% by weight of fixed carbon, 4.5% of ash, and 20% of volatile matter. The petroleum coke powder used contains 85% by weight of fixed carbon, 0.4% of ash, and 12.5% of volatile matter; the obtained combined carbonaceous reducing agent contains 77.5% fixed carbon by weight, 3.48% ash, and 18.13% volatile matter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com