Metallurgical wastewater flocculant

A waste water flocculant and flocculant technology, which is applied in metallurgical wastewater treatment, flocculation/sedimentation water/sewage treatment and other directions, can solve problems such as poor effect and achieve good flocculation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

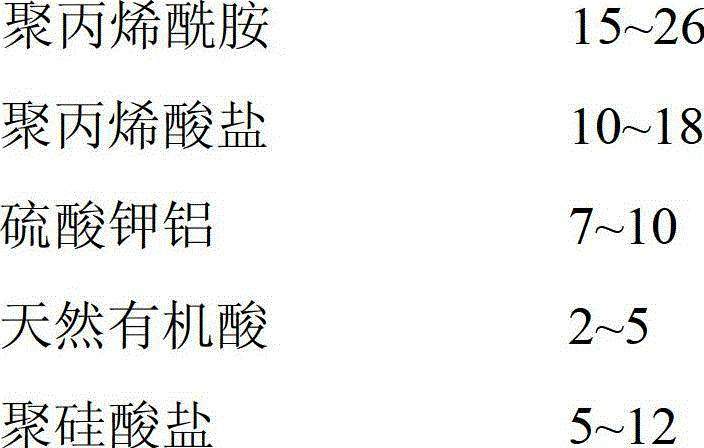

[0015] A flocculant for metallurgical wastewater consists of the following components in parts by mass:

[0016]

[0017]

[0018] In the present invention, the natural organic acid is oxalic acid.

[0019] In the present invention, the polysilicate is aluminum polysilicate.

Embodiment 2

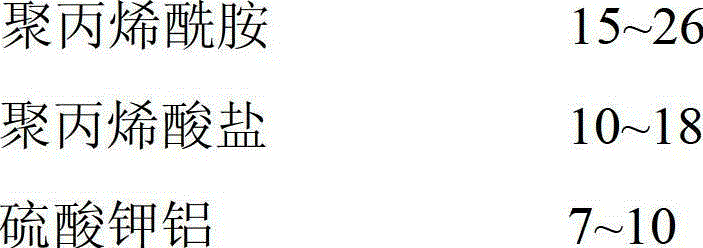

[0021] A flocculant for metallurgical wastewater consists of the following components in parts by mass:

[0022]

[0023] In the present invention, the natural organic acid is one of tannic acid.

[0024] In the present invention, the polysilicate is iron polysilicate.

Embodiment 3

[0026] A flocculant for metallurgical wastewater consists of the following components in parts by mass:

[0027]

[0028] In the present invention, the natural organic acid is a kind of tartaric acid.

[0029] In the present invention, the polysilicate is iron polysilicate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com