Zero-halogen and flame-retardation epoxy resin composition, adhesive tape and preparation method of adhesive tape

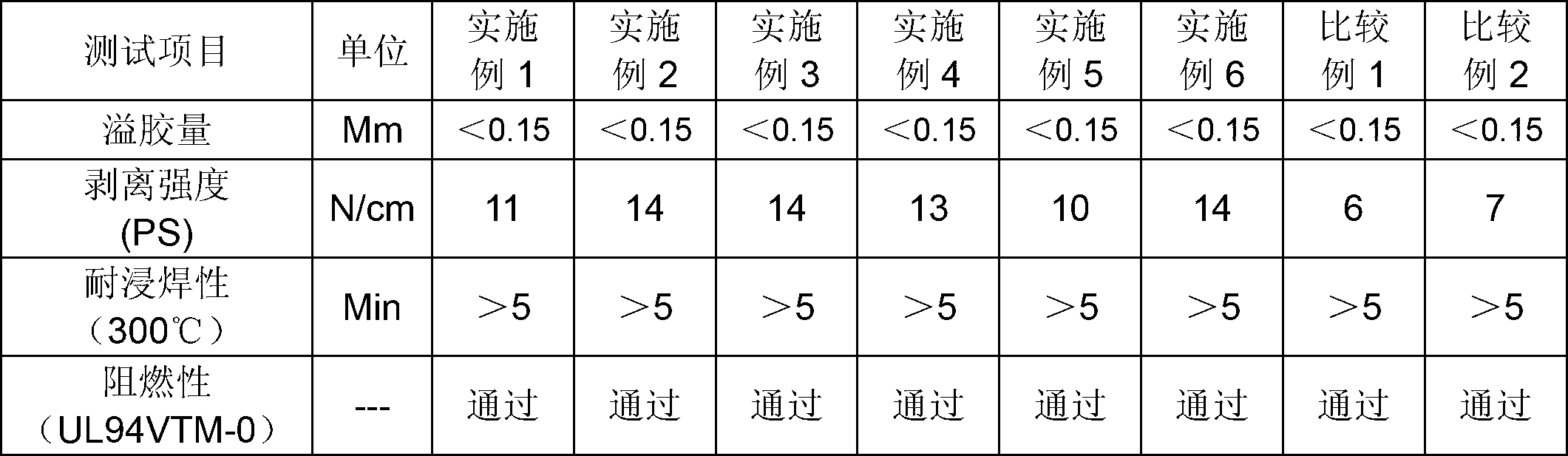

A halogenated epoxy resin, epoxy resin technology, applied in the field of halogen-free flame retardant epoxy resin composition, can solve the problems of reduced clarity of processing insulation layer, decline of corona discharge treatment effect, low speed limitation, etc., and achieves excellent size Effects of stability and processability, excellent peel strength, excellent solder dip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

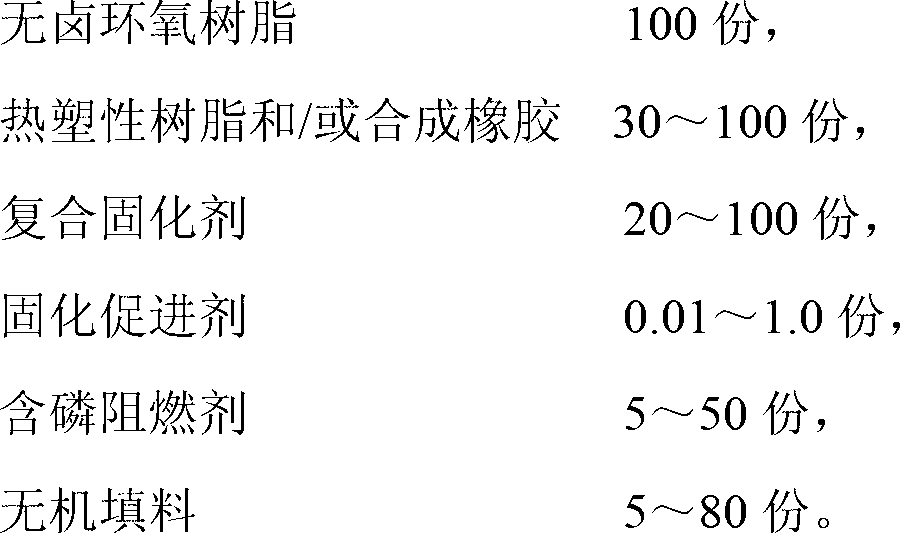

Method used

Image

Examples

Embodiment 1

[0028] 1) Use a screen printing roller to coat a polyurethane-based resin compound on one main surface of a polyimide insulating film with a thickness of 12.5 μm, and dry it online at 120°C for 2 minutes to obtain a coating composed of a polyurethane-based resin compound. The polyimide insulation film with a thickness of 0.5 μm undercoating, rolled up for use;

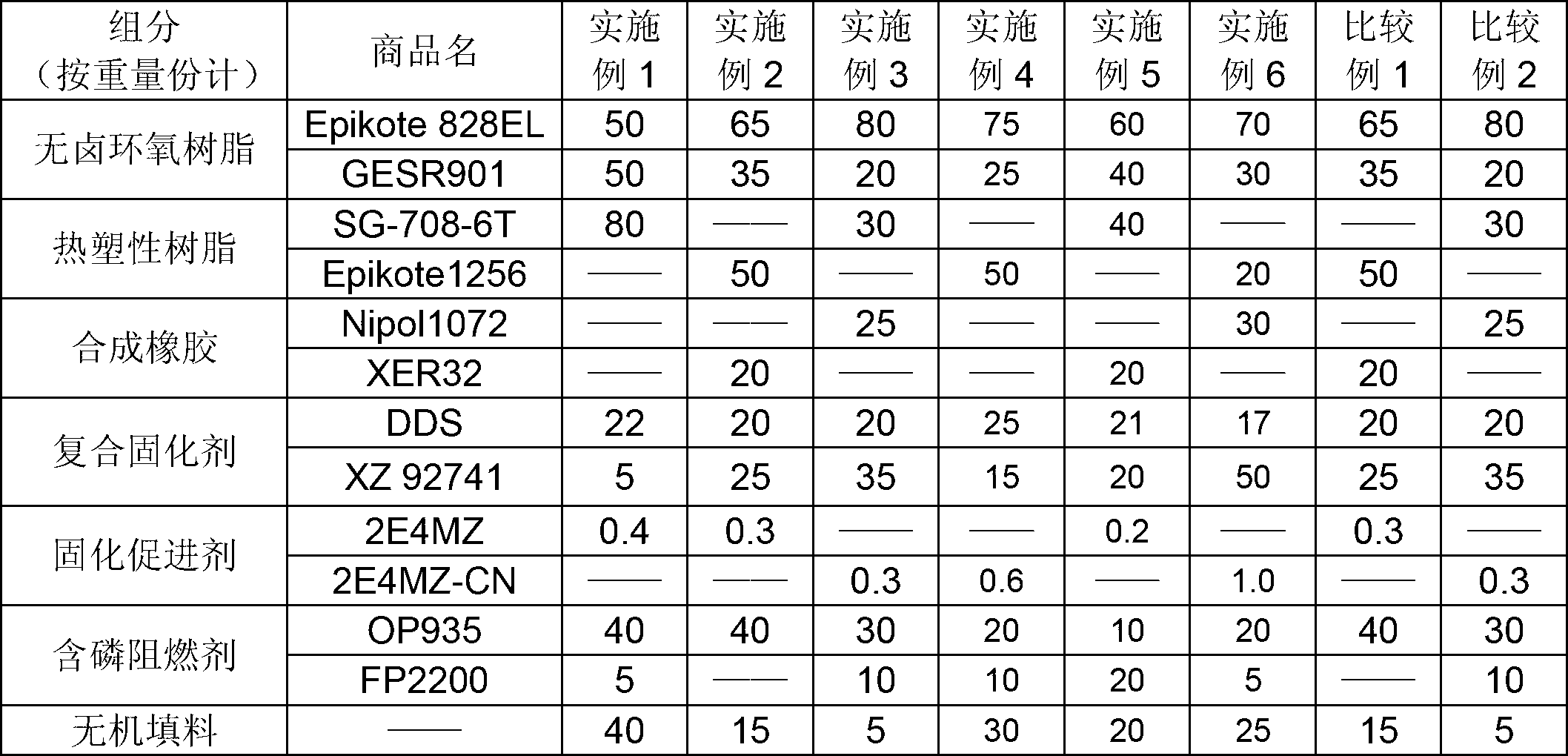

[0029] 2) Add the halogen-free flame-retardant epoxy resin composition to methyl ethyl ketone and stir to obtain a uniform mixed glue solution with a content of 35% of the halogen-free flame-retardant epoxy resin composition. The halogen-free flame-retardant epoxy resin composition The composition by weight of the product includes: 50 parts by weight of halogen-free epoxy resin A-1, 50 parts by weight of thermoplastic resin A-2, 80 parts by weight of thermoplastic resin, 22 parts by weight of diaminodiphenyl sulfone, 5 parts by weight The phosphorus-containing phenolic resin of weight part, the curing accelerator of 0....

Embodiment 2

[0032] 1) Use a screen printing roller to coat a polyurethane-based resin compound on one main surface of a polyimide insulating film with a thickness of 25 μm, and dry it online at 100°C for 4 minutes to obtain a thickness coated with a polyurethane-based resin compound. Polyimide insulating film with a base coat of 1.0 μm, rolled up for use;

[0033] 2) Add the halogen-free flame-retardant epoxy resin composition into acetone and stir to obtain a uniform mixed glue solution with a content of 40% of the halogen-free flame-retardant epoxy resin composition. The weight composition includes: 65 parts by weight of halogen-free epoxy resin A-1, 35 parts by weight of halogen-free epoxy resin A-2, 50 parts by weight of thermoplastic resin, 20 parts by weight of synthetic rubber, 20 parts by weight of di Aminodiphenylsulfone, 25 parts by weight of phosphorus-containing phenolic resin, 0.3 parts by weight of curing accelerator, 40 parts by weight of phosphorus-containing flame retardant...

Embodiment 3

[0036] 1) Use a screen printing roller to coat the polyurethane-based resin compound on both main surfaces of a polyimide insulating film with a thickness of 25 μm, and dry it online at 90°C for 5 minutes to obtain a coating composed of a polyurethane-based resin compound. A polyimide insulating film with a thickness of 1.0 μm for the primer layer, which is rolled up for use;

[0037] 2) Add the halogen-free flame-retardant epoxy resin composition to cyclohexanone and stir to obtain a uniform mixed glue solution with a content of 45% of the halogen-free flame-retardant epoxy resin composition. The halogen-free flame-retardant epoxy resin The composition by weight comprises: 80 parts by weight of halogen-free epoxy resin A-1, 20 parts by weight of halogen-free epoxy resin A-2, 30 parts by weight of thermoplastic resin, 25 parts by weight of synthetic rubber, 20 parts by weight of Diaminodiphenyl sulfone, 35 parts by weight of phosphorus-containing phenolic resin, 0.3 parts by w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com