Method for quickly determining calcium fluoride and calcium oxide contents in desulfurizer for steel making

A rapid determination and desulfurization agent technology, applied in the direction of material electrochemical variables, thermal excitation analysis, material excitation analysis, etc., can solve the problems of large fluctuations in CaF2 content, complex sample processing methods, poor accuracy and precision, etc. To achieve the effect of reducing the inspection cost, shortening the analysis cycle, and reducing the use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

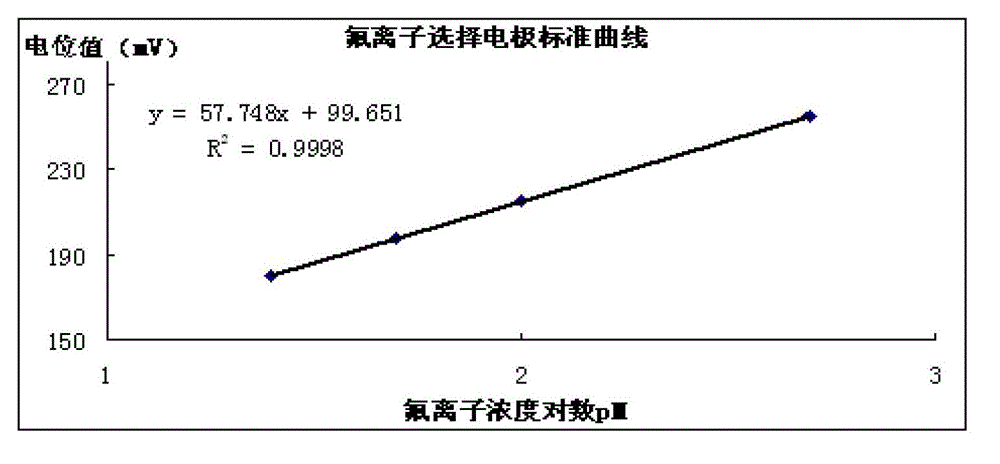

Image

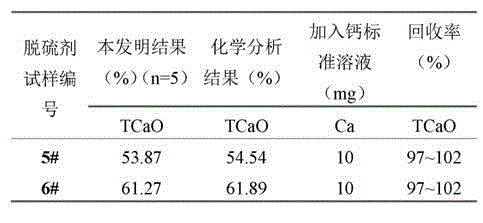

Examples

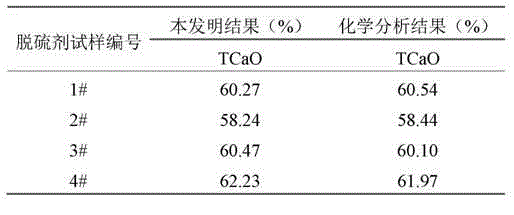

Embodiment 1

[0027] 1) Determination of TCaO content in the sample

[0028] (a) Draw the working curve of the limestone chemical analysis standard sample according to the requirements of the ICP-AES instrument;

[0029] Select the standard sample in Table 1 and follow the melting steps to dissolve and constant volume for ICP-AES analysis (can you provide the working parameters).

[0030] Table 1 Preparation table of working curve test solution

[0031]

[0032] (b) Weigh 0.1000g of the first desulfurizer sample numbered 1# and place it in a platinum crucible, add 1.0g of boric acid and anhydrous sodium carbonate in a volume ratio of 1:2 mixed flux, mix it in Melt at 950°C for 5 minutes. After cooling, place the platinum crucible in a pre-boiled dilute hydrochloric acid solution with a volume of 85mL for heating and leaching. During the leaching process, add 5mL of concentrated hydrochloric acid solution to control the acidity and keep the solution volume at 80mL. After complete leachi...

Embodiment 2

[0049] 1) Determination of TCaO content in the sample

[0050] (a) Draw the working curve of the limestone chemical analysis standard sample according to the requirements of the ICP-AES instrument;

[0051] (b) Weigh 0.2000g of the second desulfurizer sample numbered 2# and place it in a platinum crucible, add 2.0g of boric acid and anhydrous sodium carbonate in a volume ratio of 1:4 to form a mixed flux, and mix it at temperature Melting at 940°C for 10 minutes, after cooling, place the platinum crucible in a pre-boiled dilute hydrochloric acid solution with a volume of 170mL for heating and leaching. During the leaching process, add 10mL of concentrated hydrochloric acid solution to control the acidity and keep the solution volume at 160mL. After complete leaching, take it out and cool it to room temperature, then set the volume to 200mL. The dilute hydrochloric acid solution is a mixture of concentrated hydrochloric acid and water in a volume ratio of 1:10;

[0052] (c) Ta...

Embodiment 3

[0064] 1) Determination of TCaO content in the sample

[0065] (a) Draw the working curve of the limestone chemical analysis standard sample according to the requirements of the ICP-AES instrument;

[0066] (b) Weigh 0.3000g of the third desulfurizer sample numbered 3# and place it in a platinum crucible, add 3.0g of boric acid and anhydrous sodium carbonate in a volume ratio of 1:1 to form a mixed flux, and mix it at temperature Melt at 960°C for 3 minutes. After cooling, place the platinum crucible in a pre-boiled dilute hydrochloric acid solution with a volume of 240mL for complete leaching. During the leaching process, add 30mL of concentrated hydrochloric acid solution to control the acidity and keep the solution volume at 230mL. , after being fully leached, take it out and cool it to room temperature and then set the volume to 300mL, wherein the dilute hydrochloric acid solution is a mixture of concentrated hydrochloric acid and water in a volume ratio of 1:10;

[0067]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com