193nm fused quartz grating polarizer and application thereof to photoetching equipment

A technology of lithography equipment and fused silica, which is applied in the direction of microlithography exposure equipment, polarizing elements, and photolithography exposure devices, etc. It can solve the problems of energy loss in transmitted light intensity, incomplete lattice matching, and poor device stability. , to achieve low mechanical alignment accuracy requirements, small thickness, and good device stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawings and examples, but the protection scope of the present invention should not be limited thereby.

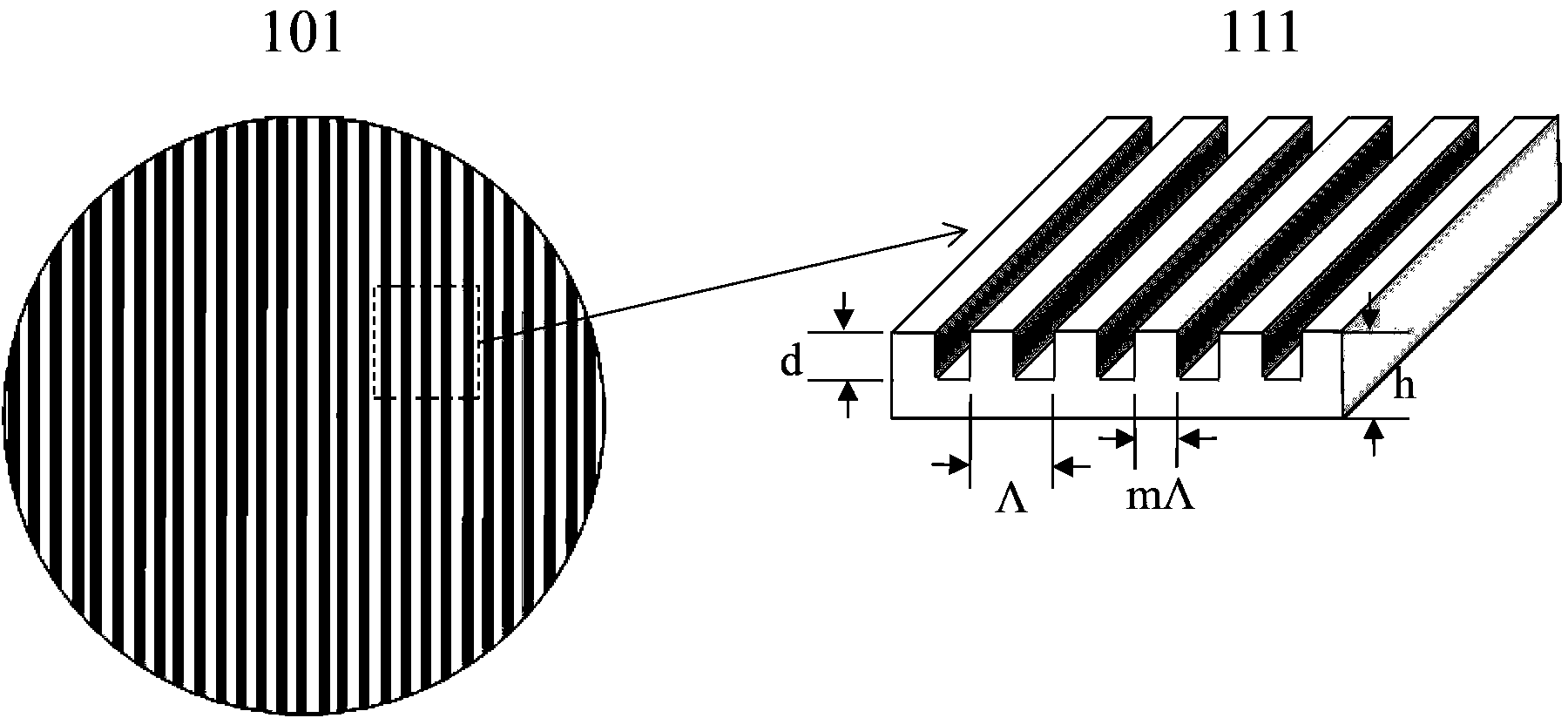

[0023] see first figure 1 , figure 1 is a schematic diagram of an embodiment of the fused silica grating polarizer of the present invention, a linear fused silica grating polarizer 101 . The characteristic size of the grating includes a line density 1 / Λ of 5260~5400 lines / mm, a grating depth d of 1.1~1.2μm, and a duty cycle m of 30%~40%. The thickness of the grating polarizer was 1 mm. The grating is a high-density deep-etched grating, and the diffraction theory it uses cannot be explained by a simple scalar method, but a vector diffraction equation must be used, that is, to solve Maxwell's equations with boundary conditions, which needs to be numerically solved by computer coding. The coupled-wave algorithm used to solve this equation has been published (see M.G. Moharam et al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com