Compound encapsulated lactic acid bacteria product and preparation method thereof

A technology for lactic acid bacteria and lactic acid bacteria fermentation liquid, applied in the field of lactic acid bacteria microcapsule products and their preparation, can solve problems such as poor temperature resistance and stability of lactic acid bacteria, and achieve the effects of avoiding bacterial activity loss, reducing production power costs, and improving tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation of embodiment 1 coated lactic acid bacteria

[0035] (1) Preparation of lactic acid bacteria fermentation broth

[0036] ①Preparation of primary seed liquid: take 1 bacterial cell preserved on a slant plane, inoculate it into the primary seed liquid medium, cultivate it in a shaker at 37±0.5°C and 180rpm / min for 8±1h after inoculation, and obtain a Grade Shake Flask Seed Solution.

[0037] The proportioning (weight-to-volume ratio W / V) method of the medium of the primary seed is as follows: glucose 1-2%, soybean peptone 1-3%, yeast extract 0.5-1%, magnesium chloride 0.05-0.1%, sodium chloride 0.2% -1%, calcium carbonate 0.2-0.5%, the filling amount of first-grade seeds is 40%, sterilized at 121°C for 30min, and ready for use.

[0038] ②Preparation of the secondary fermentation liquid: transfer the primary seed liquid to the secondary seed medium, the inoculation amount is 1-5%, the tank temperature after inoculation is controlled at 38±0.5°C, and the r...

Embodiment 2

[0059] Embodiment 2 coated lactic acid bacteria gastric acid resistance assay

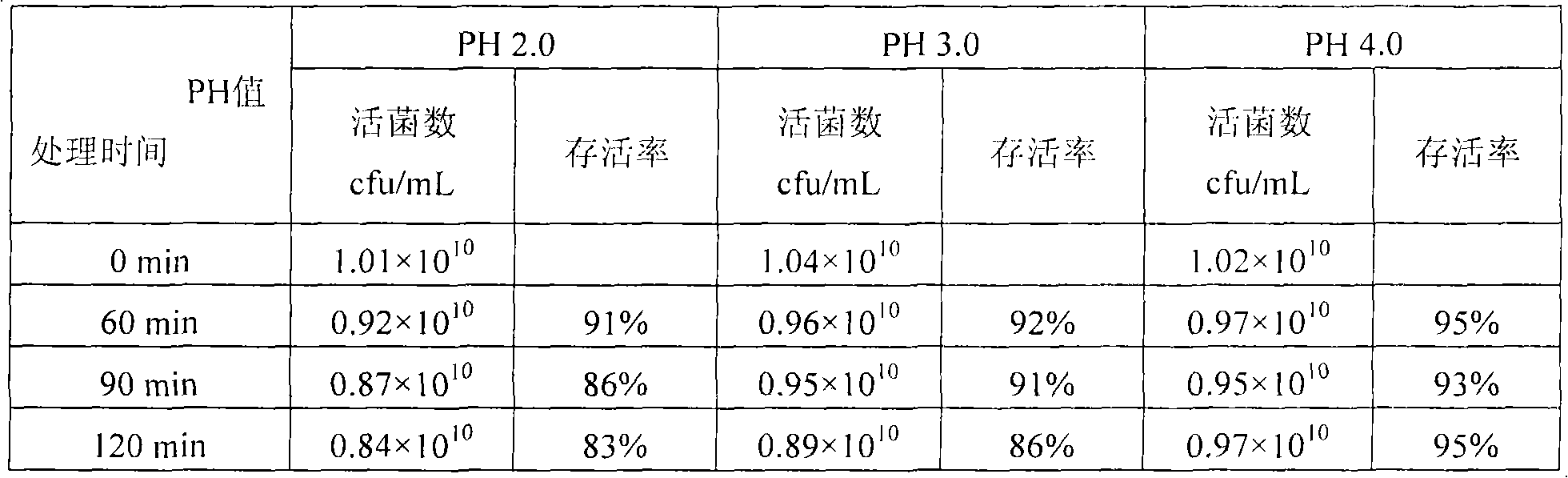

[0060] The impact of gastric acid on the survival rate of microencapsulated coated lactic acid bacteria lactic acid bacteria is shown in Table 1. The residence time of food in the stomach of livestock and poultry animals is generally 1-2 hours. This experiment artificially simulates the gastric juice environment. When the pH value of the gastric juice is 4, after 120 minutes, the survival rate of lactic acid bacteria is 95%. 3. After 120 minutes, the survival rate of lactic acid bacteria is 86%. When the pH value of gastric juice is 2, after 120 minutes, the survival rate of lactic acid bacteria is still 83%.

[0061] Table 1 Effect of gastric acid on the survival rate of microencapsulated coated lactic acid bacteria

[0062]

[0063] Tests show that the microencapsulated coated lactic acid bacteria prepared by the invention has better gastric acid resistance, can pass through the stomach of an...

Embodiment 3

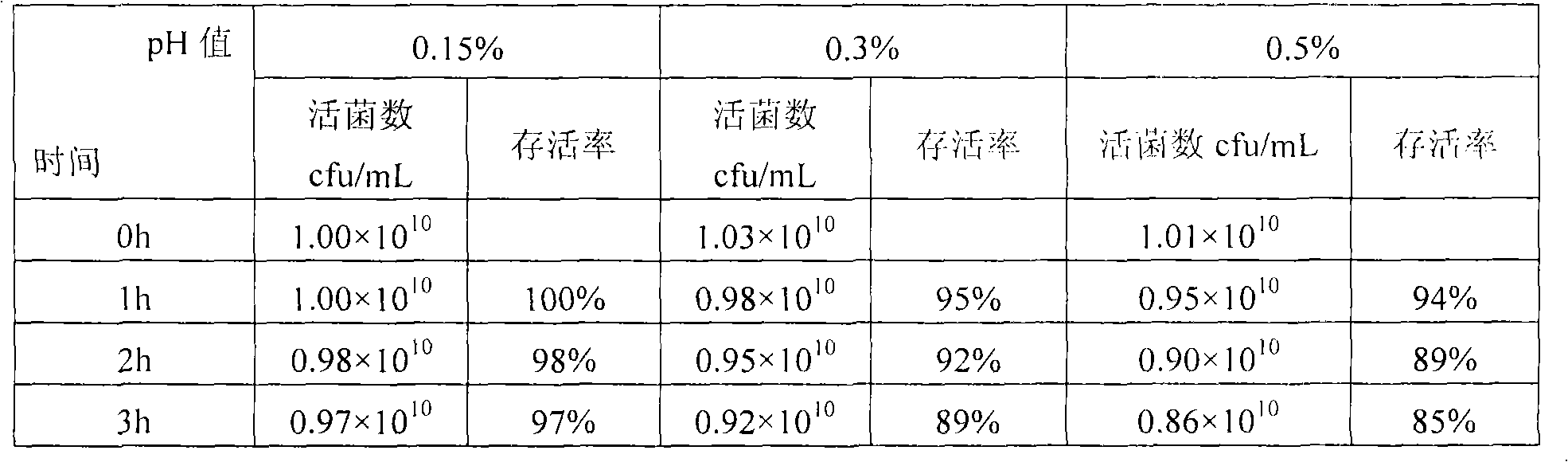

[0064] Embodiment 3 coating lactic acid bacteria bile-resistant determination

[0065] The effect of bile salts on the survival rate of microencapsulated coated lactic acid bacteria is shown in Table 2. As seen from Table 2, along with the raising of bile salt concentration, the prolongation of time, the survival rate of lactic acid bacteria constantly reduces, when bile salt concentration 0.3%, the survival rate of lactic acid bacteria after 3 hours is 89%, when bile salt concentration 0.5% , the survival rate of lactic acid bacteria was still 85% after 3 hours.

[0066] Table 2 The impact of bile salts on the survival rate of microencapsulated lactic acid bacteria

[0067]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com