Preparation method for high-molecular compound-containing metakaolin-based geopolymer cement

A technology of high molecular compound and metakaolin, which is applied in the field of preparation of metakaolin-based soil-polymer cement, can solve the problems of low flexural strength and mechanical properties of soil-polymer cement to be improved, and achieve enhanced compressive strength, simple process, easy-to-operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

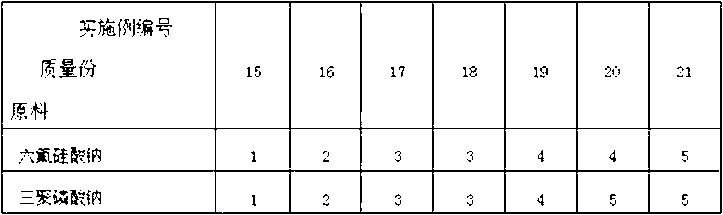

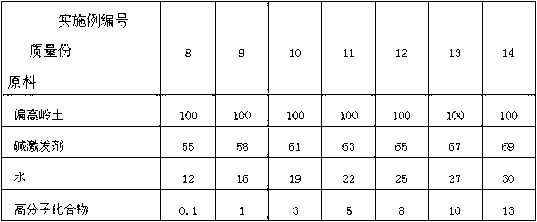

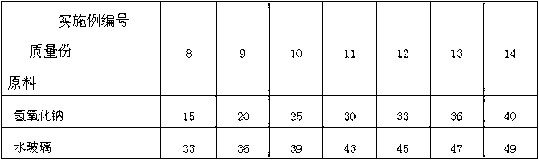

[0025] A method for preparing metakaolin-based soil polycement containing polymer compounds, which is to add 10-40 parts by mass of sodium hydroxide into 30-50 parts by mass of water glass (modulus 3.2), and stir to prepare alkali-excited cement. agent. Weigh 100-200 parts by mass of metakaolin, add 1-5 parts by mass of sodium tripolyphosphate and 1-5 parts by mass of sodium hexafluorosilicate, then add 40-60 parts by mass of alkali activator and 10-40 parts by mass part of water, mix and stir to form a slurry, and add 0.1-15 parts by mass of polyvinyl alcohol. After stirring for 5 minutes, pour into a mold of 20mm×20mm×20mm, put it into a curing box with a temperature of 20±3°C and a relative humidity of 90%-95% for 24 hours. Remove the mold and continue curing to the corresponding age (1d, 3d or 7d), to obtain the final product - metakaolin-based geopolymer cement containing polymer compounds. The compressive strength of the prepared cement added with polyvinyl alcohol was...

Embodiment 2

[0027] A method for preparing metakaolin-based soil polycement containing polymer compounds, which is to add 10-40 parts by mass of sodium hydroxide into 30-50 parts by mass of water glass (modulus 3.2), and stir to prepare alkali-excited cement. agent. Weigh 100-200 parts by mass of metakaolin, add 1-20 parts by mass of polyacrylamide, add 1-5 parts by mass of sodium tripolyphosphate and sodium hexafluorosilicate, mix well, and then add alkali activator 40- 60 parts by mass and 10-40 parts by mass of water, mixed and stirred for 5 minutes to form a slurry, and poured into a 20mm×20mm×20mm mold, placed in a room with a temperature of 20±3°C and a relative humidity of 90%-95%. Curing in the curing box for 24 hours. Remove the mold and continue curing to the corresponding age (1d, 3d or 7d) to obtain the final product - metakaolin-based soil-polymer cement containing polymer compounds. It is measured that the compressive strength of the prepared cement is higher than that of th...

Embodiment 3

[0029] A method for preparing metakaolin-based soil polycement containing polymer compounds, which is to add 10-40 parts by mass of sodium hydroxide into 30-50 parts by mass of water glass (modulus 3.2), and stir to prepare alkali-excited cement. agent. Weigh 100-200 parts by mass of metakaolin, add 1-15 parts by mass of epoxy resin, add 1-5 parts by mass of sodium tripolyphosphate and 1-5 parts by mass of sodium hexafluorosilicate, mix well, and then Add 40-60 parts by mass of alkali activator and 10-40 parts by mass of water, mix and stir for 5 minutes to form a slurry, and inject it into a mold of 20mm×20mm×20mm. Curing in the curing box for 90%-95% for 24 hours. Remove the mold and continue curing to the corresponding age (1d, 3d or 7d) to obtain the final product - metakaolin-based soil polycement containing polymer compounds. The compressive strength of the prepared cement was measured to be higher than that of the cement without epoxy resin added.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com