Method and device for separating and recycling butanone by three-tower pressure-variable rectification and heat integration

A technology for pressure swing rectification and recovery of methyl ethyl ketone, which is applied in the separation/purification of carbonyl compounds, chemical industry, climate sustainability, etc. It can solve the problems of high equipment requirements, inability to meet the separation requirements of complex systems, and difficult recovery, etc. problem, to achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

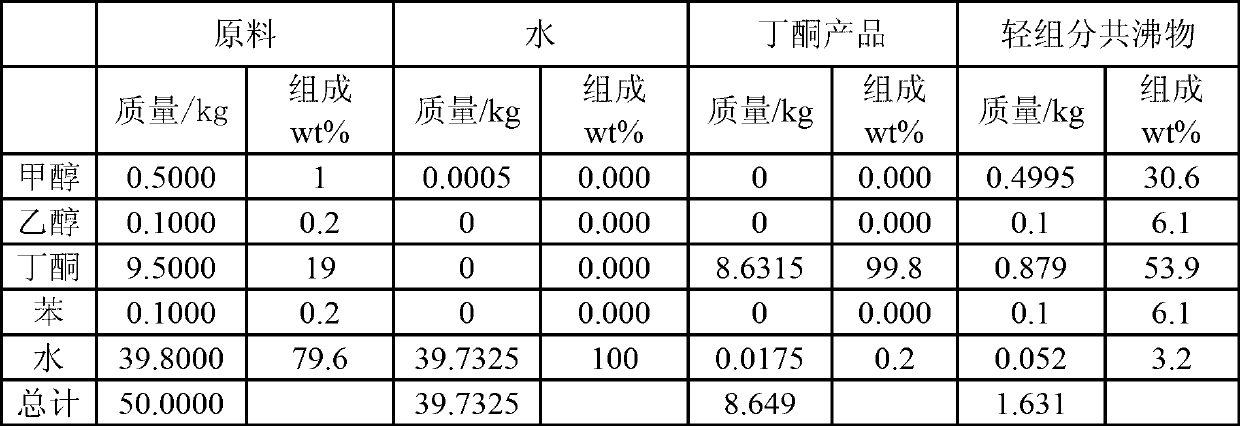

[0030] Table 1 Raw material composition

[0031] components

Contentwt%

1

0.2

butanone

19

0.2

water

79.6

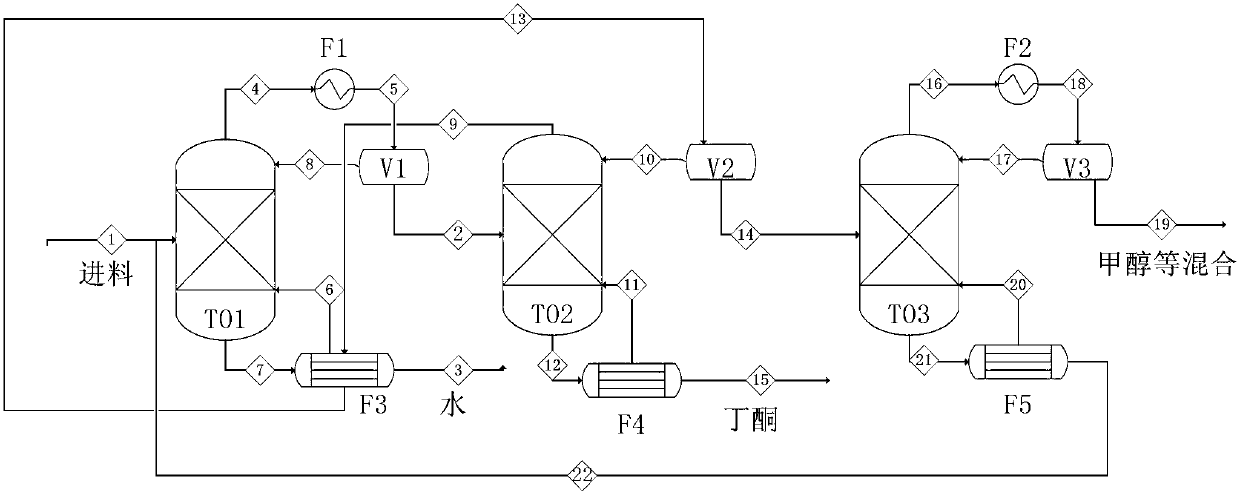

[0032] Feed raw material 1 (the raw material composition is shown in Table 1) into the dehydration tower T01 at 50kg / h for atmospheric distillation operation, the feed temperature is 30°C, the tower top pressure is controlled at 100kpa (absolute pressure), and the tower top temperature is 72 °C, the temperature of the tower kettle is 100 °C, the mass reflux ratio is controlled at 2, and the top of T01 is extracted as an atmospheric azeotrope 2, and the atmospheric pressure azeotrope 2 is injected into the methyl ethyl ketone product column T02 by pressurization, and the top pressure Control 550kpa (absolute pressure), the temperature at the top of the tower is 135°C, the temperature at the bottom of the tower is 150°C, the mass reflux ratio is controlled at 10, the butanone...

Embodiment 2

[0041] Table 4 raw material composition

[0042] components

Contentwt%

9

[0043] ethanol

0.5

butanone

29.5

benzene

1

water

60

[0044] Feed raw material 1 (the raw material composition is shown in Table 4) into the dehydration tower T01 at 75kg / h for normal pressure operation, the feed temperature is 30°C, the pressure at the top of the tower is controlled at 120kpa (absolute pressure), and the temperature at the top of the tower is 77.2°C. The temperature of the tower kettle is 104.8°C, the mass reflux ratio is controlled at 1, and the top of T01 is produced as an atmospheric azeotrope 2, and the atmospheric pressure azeotrope 2 is injected into the methyl ethyl ketone product column T02 through pressurization, and the top pressure is controlled at 1000kpa ( absolute pressure), the temperature at the top of the tower is 151°C, the temperature at the bottom of the tower is 173°C, th...

Embodiment 3

[0052] Table 7 raw material composition

[0053] components

Contentwt%

8

ethanol

0.2

butanone

30

benzene

0.3

water

61.5

[0054] Feed raw material 1 (the raw material composition is shown in Table 4) into the dehydration tower T01 at 50kg / h for normal pressure operation, the feed temperature is 30°C, the pressure at the top of the tower is controlled at 150kpa (absolute pressure), and the temperature at the top of the tower is 84°C. The temperature at the bottom of the tower is 112°C, the mass reflux ratio is controlled at 0.5, the top of T01 is extracted as atmospheric azeotrope 2, and the atmospheric pressure azeotrope 2 is pumped into the methyl ethyl ketone product column T02 through pressurization, and the pressure at the top of the tower is controlled at 1500kpa ( Absolute pressure), the temperature at the top of the tower is 162°C, the temperature at the bottom of the tower is 174°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com